Airports recruit NEXT GEN

Airports recruit NEXT GEN

ORDERS UP: RMIT turns coffee to concrete

Protect your critical assets with the most reliable systems made in Australia.

Century Yuasa has been protecting critical power assets for 30 years with our local design, construct and onsite teams. Our DC systems are built with the best of global technologies and supported with the globally recognised Yuasa VRLA batteries which are the only batteries you can genuinely rely on to protect your critical assets and business services year after year.

To learn more about Australia’s own DC power systems, maintenance services, and the Yuasa range of VRLA batteries, visit our website.

For enquiries call 1300 364 877 https://cyb.com.au/industries-markets/industrial

Published by

Monkey Media Enterprises

ABN: 36 426 734 954

C/- The Commons, 36–38 Gipps St, Collingwood VIC 3066 P: (03) 9988 4950 monkeymedia.com.au info@monkeymedia.com.au infrastructuremagazine.com.au news@infrastructuremagazine.com.au

Editor April Shepherd

Assistant Editor Stephanie Nestor

Journalists

Tess Macallan, Kody Cook, Steph Barker, Yasmin Isaacs

National Media Executives

Rima Munafo, Brett Thompson, Ryan Sheehan

Design Manager

Alejandro Molano

Senior Designer

Luke Martin

Designers

Danielle Harris, Jacqueline Buckmaster

Marketing Manager

Radhika Sud

Marketing Associates

James Holgate, Rhys Dawes

Digital Marketing Assistants

Isabella Predika, Emily Gray

Publisher Chris Bland

Managing Editor

Laura Harvey

ISSN: 2206-7906

As we say goodbye to another year, and 2024 peaks over the horizon, I am sure many of you are excited for some R&R after what has been yet another eventful year.

Our last issue of 2023 brings with it two huge features; Airports and Rail, and two huge events; the Australian Airports Association (AAA) National Conference, and AusRAIL. To celebrate these two highlights in the events calendar, we have brought together some of the hottest projects in the sectors.

For rail, we cover Adelaide Metro’s new electric powered fleet (pictured on the cover), Parramatta’s light rail and New South Wales’ regional rail overhaul – showcasing regional, metro and suburban rail projects.

In the airport sector, we have an eye-opening piece from James Goodwin, AAA Chief Executive, discussing the industry’s career-drive, and we also hear from Perth and Ballarat airports respectively about the projects supporting the future of aviation.

Outside of these major features we cover some of the hottest topics in the industry at the moment, such as the Level Crossing Removal Project garnering global attention, gender diversity in the sector, and how cities are preparing for future population growth.

Industry leaders are looking to the future, as TasWater tells us all about their future-proof plan for Hobart’s water supply and RMIT researcher, Dr Rajeev Roychand, shares findings from a new report discussing how leftovers from your morning coffee can be turned into enhanced concrete to support sustainable construction.

As always, I look forward to delivering the latest news and content from the sector, and if you have a story idea or a tip, reach out – my digital door is always open.

GENDER DIVERSITY CRITICAL TO ADDRESSING OUR

SKILLS SHORTAGE

As the infrastructure sector continues to face a significant skills and labour shortage, we also face a very real solution — improving gender diversity.

TASWATER FUTURE-PROOFING GREATER HOBART’S WATER NEEDS

A new chapter of water security for 200,000 customers in southern Tasmania was written in September 2023, with TasWater officially opening its upgraded Bryn Estyn Water Treatment Plant (WTP).

MAXIMISING WATERPROOFING PERFORMANCE, LONGEVITY: THE VITAL ROLE OF MAINTENANCE

OPINION: AN INDUSTRY ON THE CUSP OF CHANGE

BANNING ENGINEERED STONE: PROTECTING LIVES AND ENSURING WORKER SAFETY

TURNING COFFEE INTO CONCRETE: RMIT STUDY BREAKS FRESH GROUND

As a country known for its thriving coffee culture, it’s no surprise that Australia generates 75 million kilograms of ground coffee waste every year. Most of this ends up in landfill, contributing to greenhouse gas emissions and exacerbating environmental degradation. To combat this, a team of RMIT University researchers are on a mission to transform discarded

into a

that

support

HOW MELBOURNE WATER IS KEEPING UP WITH A GROWING POPULATION

THE INVISIBLE WORK TOWARDS ACHIEVING A SUSTAINABLE FUTURE

BUILDING A RESILIENT ROAD NETWORK WITH THE NEW FITZROY RIVER BRIDGE

The Fitzroy River Bridge formed part of a vital freight route in Western Australia until it was permanently damaged following a cyclone, prompting the construction of a replacement bridge. With a disaster resilient design, the new bridge promises to support this remote road network by reconnecting communities and industries.

PARRAMATTA LIGHT RAIL DELIVERS SUSTAINABLE INFRASTRUCTURE

From its Australian-first innovative rail boot system to its award-winning green track, the Parramatta Light Rail Stage 1 project is leading industry best practice in delivering sustainable public transport infrastructure for the New South Wales community.

KEEPING RAILWAYS ON TRACK WITH INNOVATIVE REMEDIATION SOLUTIONS

HOW TAILORED LIDAR SOLUTIONS ARE CHANGING THE GAME

ADELAIDE METRO NET-ZERO PUBLIC TRANSPORT

In the pursuit of its net-zero emissions by 2050 target, South Australia is taking aim at its largest emissions contributor: transportation. Here Infrastructure Magazine explores what the future of sustainable public transport will look like in Adelaide as Adelaide Metro begins its transition to a zero-emissions system.

GETTING ON TRACK WITH NSW’S REGIONAL RAIL UPGRADE

In late July 2023, construction activities began to extend the existing rail siding at Coolamon, New South Wales. As part of the Fixing Country Rail Program, the project is aimed at removing freight bottlenecks, improving efficiency and making the state’s rail network safer for all services and customers.

PREPARE TO TAKE OFF WITH MY AIRPORT CAREER

Airports are bustling hubs of activity, connecting people, cultures, and destinations, but behind all the action exists a hidden world of opportunities.

INNOVATIVE TECHNOLOGIES FOR RAPID REPAIR AT AIRPORTS

DESTINATION WA: PERTH AIRPORT SUPPORTING REGIONAL AVIATION SERVICES

IOT & CLOUD COMMUNICATION

NHP’S MEDIUM VOLTAGE SOLUTIONS

STRENGTHENING OT CYBERSECURITY: A STRATEGIC IMPERATIVE

LEVEL CROSSING REMOVAL PROJECT’S DIGITAL SOLUTIONS RECEIVE GLOBAL RECOGNITION

For Melbourne residents, the Level Crossing Removal Project has become a part of daily life, as many locals take the city-wide works in their stride, with the knowledge that the transformational project will make the city safer and more efficient for generations to come. To make this momentous project as efficient as possible, the Victorian Government has utilised a plethora of digital solutions – garnering international attention, and awards.

RIVERLINK: A MODEL OF PROACTIVE SUBSURFACE RISK MANAGEMENT

IMPROVING SAFETY, EFFICIENCY IN RUGGED INDUSTRIES: THE BENEFITS OF VOICE RECOGNITION SOFTWARE

EARLY DETECTION: HOW SYDNEY WATER’S IOT ROLLOUT IS PREVENTING OVERFLOWS

With blockages and overflows being frequent problems for wastewater infrastructure, Sydney Water is undertaking a $15 million wastewater monitoring internet of things (IoT) deployment across its network. Already, Sydney Water is saving hundreds of thousands of dollars per month with sensors that can detect blockages before they cause damage.

6. EXPERIENCES AS A WOMAN IN ENGINEERING – MEET KATE FALLON

8. $70M MAJOR ROAD EXTENSION COMPLETE

9. $2M ENGINEERING SCHOLARSHIP PROGRAM TO SUPPORT WORKFORCE

10. WA COUNCIL TO TEST AUSTRALIA’S FIRST TRACKLESS TRAM

11. POWERLINK CALLS FOR LOCAL SUPPLIERS FOR COPPERSTRING 2032

12. MONARO HIGHWAY UPGRADE CONTRACT AWARDED

13. QUEST LARGEST BY LOCATION, FASTEST GROWING ACCOMMODATION PROVIDER IN NZ

Adam Copp was appointed Acting CEO of Infrastructure Australia in August 2022. An accomplished and transformational public sector leader, he has over 15 years’ experience in the Federal Government holding a range of policy, strategy and public affairs roles across infrastructure, workplace relations and the Council of Australian Governments. Prior to his appointment, Mr Copp was Infrastructure Australia’s Chief Operating Officer.

As Chief Operating Officer, Mr Copp was responsible for leading Infrastructure Australia’s Strategy, Finance, People & Culture and Digital Technology functions. He joined Infrastructure Australia in 2014 and set up the public affairs and stakeholder engagement function, before expanding his role across the other operational functions of the business. He is a passionate advocate for Reconciliation and First Nations engagement.

Principal Technical Safety and Risk Engineer, Kent

Kate Fallon has over ten years of safety engineering experience in the oil and gas industry. She has a wide variety of exposure in the industry, including knowledge and understanding of working on large-scale projects providing safety and risk engineering input and support. Ms Fallon joined Kent in 2022 as a Principal Technical Safety and Risk Engineer in Perth, Australia.

Chief Executive, Australian Airports Association (AAA)

James Goodwin is an experienced executive and non-executive director with a corporate affairs and public policy background, with a particular interest in the transport, aviation and infrastructure sectors.

He was appointed Chief Executive of the Australian Airports Association in early 2020 and successfully guided the AAA through one of its most difficult challenges in history.

He continues to lead the AAA in supporting its members and advocating for national airport policy to ensure the nation has a thriving aviation system that is safe, secure, competitive, and environmentally responsible, with a skilled workforce to benefit all Australians and visitors.

A former journalist and news presenter, he worked for major network news outlets in Sydney and Canberra, including several years in the Federal Parliamentary Press Gallery.

Chief

Executive Officer,Thoracic Society of Australia and New Zealand (TSANZ)

Vincent So is CEO of The Thoracic Society of Australia and New Zealand (TSANZ). TSANZ is the only health peak body representing a range of professions (medical specialists, scientists, researchers, academics, nurses, physiotherapists, students, and others) across various disciplines within the respiratory/sleep medicine field in Australia and New Zealand.

Dr Rajeev Roychand Research Fellow, RMIT University

Dr Rajeev Roychand Research Fellow, RMIT University

Dr Rajeev Roychand is a Postdoc Research Fellow working at RMIT University, Melbourne. He has more than 15 years’ experience in material research and structure design. He has published 46 high impact research papers and has secured more than $1 million in research funding. Nine of his research papers have extensively been covered by the international media. He is a recipient of the RMIT award for impact and collaboration (2022).

Michael Kilgariff Principal, Kilgariff AdvisoryMichael Kilgariff is a former CEO of Roads Australia and Managing Director of the Australian Logistics Council. In these and previous roles, he has developed a reputation for building strong working relationships across industry and government, with the aim of supporting and achieving outcomes that are mutually beneficial to industry, government and the community.

In recognition of his work in this area, Michael won the Transport and Logistics Executive of the Year in the CEO Magazine 2014 Executive of the Year Awards

Infrastructure Magazine caught up with Kate Fallon, Principal Technical Safety and Risk Engineer at Kent, for an exclusive Q&A where Kate shared with us her experiences as an engineer.

Kate discusses the importance of striking a balance between career and motherhood, emphasising the need for greater support and encouragement for women in engineering.

What made you choose a career in engineering?

I finished high school at 17 with my highest marks in mathematics and chemistry so a teacher suggested I study Engineering. When I looked at the number of women studying Engineering, Chemical Engineering had the highest percentage of female graduates and that was actually a key decision in choosing to study Chemical Engineering.

What are the advantages/challenges of being an engineer in a male-dominated industry?

Let’s be honest, Engineering and Oil and Gas has always been a “man’s world”. As a graduate, I would be in meetings and workshops and asked if I was the receptionist or HR. But in the past ten years there has been a huge shift in promoting women and ensuring we acknowledge and celebrate their successes. My current manager on the project I am seconded to is a woman and she is one of the best bosses I have worked with.

Choosing to be both an engineer and a parent I find often presents unique challenges to women. Women will usually take maternity leave when they have a baby. I know women that have felt rushed to return to their positions otherwise they would

be overlooked for promotions or career progression. I know women whose employers have made the assumption that their interests would now be with their kids and not their jobs and subsequently given smaller roles on projects.

We need to support engineers that choose to be mothers and encourage their return to work when they are ready, without holding their careers back or penalising them. We need to acknowledge that women, regardless of parenthood, are as much a part of the workforce and as important as the men who did not take any parental leave.

In recent years, I have seen companies install creches and offer flexible working arrangements to allow employees to be mothers as well as be part of the workforce which is truly amazing.

I am very fortunate to work for Kent, which is a company that embraces women and allows them the flexibility to do their job and do it well, as well as be a mother.

Is enough being done to promote/encourage women in engineering?

There could be a bigger push at the high school or university level to promote young women to study engineering. A few years after I graduated, some universities were offering women scholarships to study and there are now STEM programs in high schools which is great, but there is still more that can be done.

I joined WISE (Women in Subsea Engineering) and they hold regular events to celebrate women, which is a great way to bring people together.

What has been your biggest win throughout your time at Kent?

When the junior engineers realised they could approach me for advice. I joined Kent in a man-only team, where I am still the only female, so now I regularly look to support junior engineers by sharing my experience and knowledge. Hearing from them on their own work and career journeys, and sharing my own perspective, allows for transparency and open conversations that have created a great team dynamic.

The Queensland Government has officially opened the Sunshine Coast’s $70 million Bells Creek Arterial Road, which aims to reduce travel times to improve the state’s transportation into the future.

The State Government invested $35 million into the road’s construction and development.

Queensland Premier, Annastacia Palaszczuk, State Minister for Transport and Main Roads, Mark Bailey, and Member for Caloundra, Jason Hunt, officially opened the 8km extension of Bells Creek Arterial Road, completing the 11.9km link between the Bruce Highway and Caloundra Road.

Delivered as part of a $70 million project, the road was co-funded by development company Stockland and the State Government, aiming to provide a vital second gateway from the Bruce Highway to the southern Sunshine Coast.

The project has delivered significant economic benefits, including the creation of over 300 direct jobs and 550 indirect jobs over the life of the project, with Sunshine Coast business Shadforth Civil Contractors appointed to build the road.

Ms Palaszczuk, said, “The population of the Sunshine Coast is booming – one of the reasons our government put funding on the table to bring its construction forward from 2030.

“We promised the accelerated delivery of the Bells Creek Arterial in 2020 and today we are delivering on that commitment.

“More than 50,000 drivers use Caloundra Road every day so this brand new road will give those people a crucial second access to the Bruce Highway,” Ms Palaszczuk said.

“Our Big Build is not just a promise, it’s a guarantee. A guarantee that our government will build the roads, bridges, school, hospitals and infrastructure Queenslanders need now and in

Mr Bailey said the development of the Bells Creek Arterial Road marks the start of the government’s transportation projects across the state.

“Bells Creek Arterial Road now spans nearly 12km and will bust congestion on the Sunshine Coast, thanks to local member Jason Hunt’s tireless advocacy, and the workers who got the job done,” Mr Bailey said.

“As an avid bike rider, I’m excited to announce we’ve delivered improved active transport connections, including an overpass bridge from Baringa and Nirimba, helping more Queenslanders get outside and enjoy our great lifestyle.

“And that’s not all – over the next four years, the State Government is investing over $32.1 billion in road and transport projects all over Queensland, supporting 25,200 good, secure jobs across the state.

“We’re delivering more lanes, better roads and safer interchanges, helping Queenslanders get home sooner and safer.”

Featured image: Bells Creek Arterial. Image: Queensland Government.

Future Charles Sturt University students are being encouraged to apply for Transgrid’s engineering scholarships – a $2 million program aiming to boost the infrastructure workforce.

Applications are now open for 25 scholarships for first-year engineering students at the university’s Bathurst campus in 2024, under Transgrid’s Engineering Scholarship Fund.

The fund will support 100 engineering students at the university’s Bathurst campus between 2023 and 2026 to help grow a skilled workforce in regional Australia as the clean energy transition accelerates.

Executive General Manager of Major Projects, Gordon Taylor, said that Transgrid is delivering the critical infrastructure and priority projects identified by the Federal and New South Wales Governments to enable Australia’s clean energy transition.

“Our major projects such as EnergyConnect, HumeLink and VNI West will require world-class engineering expertise and we are delighted to support the next generation of engineers to help build our skilled workforce as we enable Australia’s renewable energy transformation,” Mr Taylor said.

“I encourage prospective students to apply for a scholarship with each recipient to receive $20,000 over four years to help meet the costs associated with their study, living expenses and learning resources.”

The first 17 engineering scholarships were awarded earlier this year, with recipients hailing from New South Wales regional centres including Albury, Bathurst, Dubbo, Orange, Port Macquarie and Wagga Wagga, as well as Victoria and Queensland.

Bachelor of Technology (Civil)/Master of Engineering (Civil) student, Olivia Tait, from Wagga Wagga, received a Transgrid scholarship to help with the cost of her studies, including travel to and from the Bathurst campus.

Ms Tait encouraged prospective engineering students to apply for a scholarship to help them realise their goal of becoming a professional engineer.

“Receiving the Transgrid engineering scholarship has really aided me in my studies and allowed me to focus more on my academic goals and progress my career goals,” Ms Tait said.

“I hope to become a professional engineer in the civil engineering field and make a positive change in the community and improve our community infrastructure.”

Charles Sturt Head of the School of Engineering, Mathematics and Engineering, Associate Professor Michael Kemp, said the Transgrid scholarships were a great addition to the paid internships already offered through the university’s engineering courses.

“A Transgrid scholarship will help a student in the earlier part of their course before the internship has started, with half the value being offered in the first year when it is most needed,” Professor Kemp said.

“This allows a student to fully engage from the beginning in the real world team based engineering challenges as well as starting the innovative and flexible ‘topic tree’, offered at Charles Sturt.”

Transgrid scholarships are open for commencing students undertaking a Bachelor of Engineering (Civil) (Honours) or a Bachelor of Technology (Civil)/ Master of Engineering (Civil) at Charles Sturt University.

Applications are now open for 2024, with the early bird round closing on 26 November and offers to go out on 12 December. Applications will remain open with a second round of offers to be made on 22 January.

Australia’s first Trackless Tram has arrived in the City of Stirling after a long journey from Shanghai, where it will soon be undergoing testing to determine its suitability for use along Scarborough Beach Road.

The $2 million business case and trial for the 30m-long Trackless Tram has been funded by the Federal Government, with the project being delivered with partners Curtin University, CRRC, Shanghai Electric and Infrastructure Technology Solutions.

Through the trial, a range of experts will examine how this technology works to help determine whether it can be implemented along Scarborough Beach Road.

Council said that, with its efficient and eco-friendly features, the trackless tram is part of Stirling’s vision for a sustainable region with a local focus.

It is hoped the tram will connect people to busy, vibrant areas, creating better accessibility and generating urban redevelopment within the Scarborough Beach Road Activity Corridor.

Representing the latest in sustainable mid-tier transport technology, Trackless Trams have the potential to achieve positive economic, business, transport, innovation and sustainability outcomes.

This new mode of commuting could be a game changer for Perth and encourage people to make the switch from cars to public transport.

City of Stirling said that it’s part of the region’s plan to reduce congestion, improve access to employment and contribute to urban regeneration.

As a net-zero emission vehicle the Trackless Tram will also support a reduction in carbon emissions as well as decreasing the number of cars on the road.

However, Council said it will require collaboration across community, business and government sectors.

The trial of the Trackless Tram will commence over the coming weeks and will run through to November, where locals and stakeholders will have the chance to ride the tram and be part of some user-experience testing.

In conjunction with event partners and sponsors, the City will also present a Net Zero Transit Symposium on 21 and 22 November at Rendezvous Scarborough.

Powerlink and its construction partners, UGL and CPB, have released 40 works packages for the CopperString 2032 project, giving local suppliers the opportunity to work on Australia’s largest transmission works.

These packages cover a range of activities and services, such as engineering, construction, environmental management, logistics, camp construction, haulage and communications.

They are designed to maximise the opportunities for local businesses and communities to participate in the

delivery of the nation-building project, which will stimulate new industries and innovation in the North West Minerals Province and aims to unlock the renewable energy potential of North Queensland.

Powerlink Executive General Manager for Major Projects, Ian Lowry, said the release of these packages sends a clear signal to the market that Powerlink is ready to start work.

“Since Powerlink took on this project earlier this year, we have been focused on starting work on the ground as soon as possible,” Mr Lowry said.

“Our process is not just about finding the best value for money, but also about finding the best fit for our vision. That’s why we want to hear from you, the local businesses and suppliers that know the region and identify who has the capability, capacity, and experience to deliver high-quality outcomes for the CopperString 2032 project.

“We want to work together to create a sustainable and resilient supply chain that benefits local communities along the CopperString line.

“This is an opportunity for regional businesses to register their interest in being a part of a project that will transform North and North-West Queensland for generations to come.”

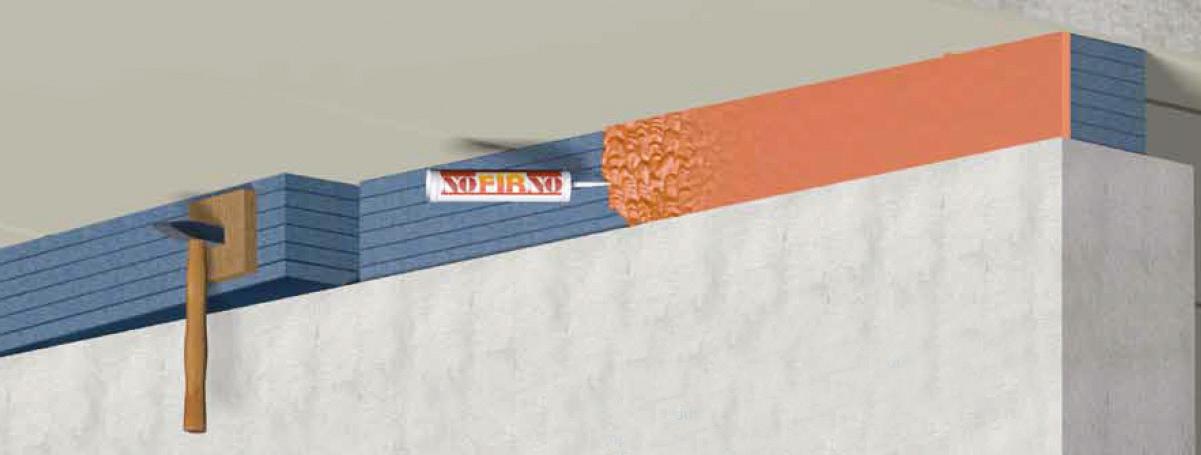

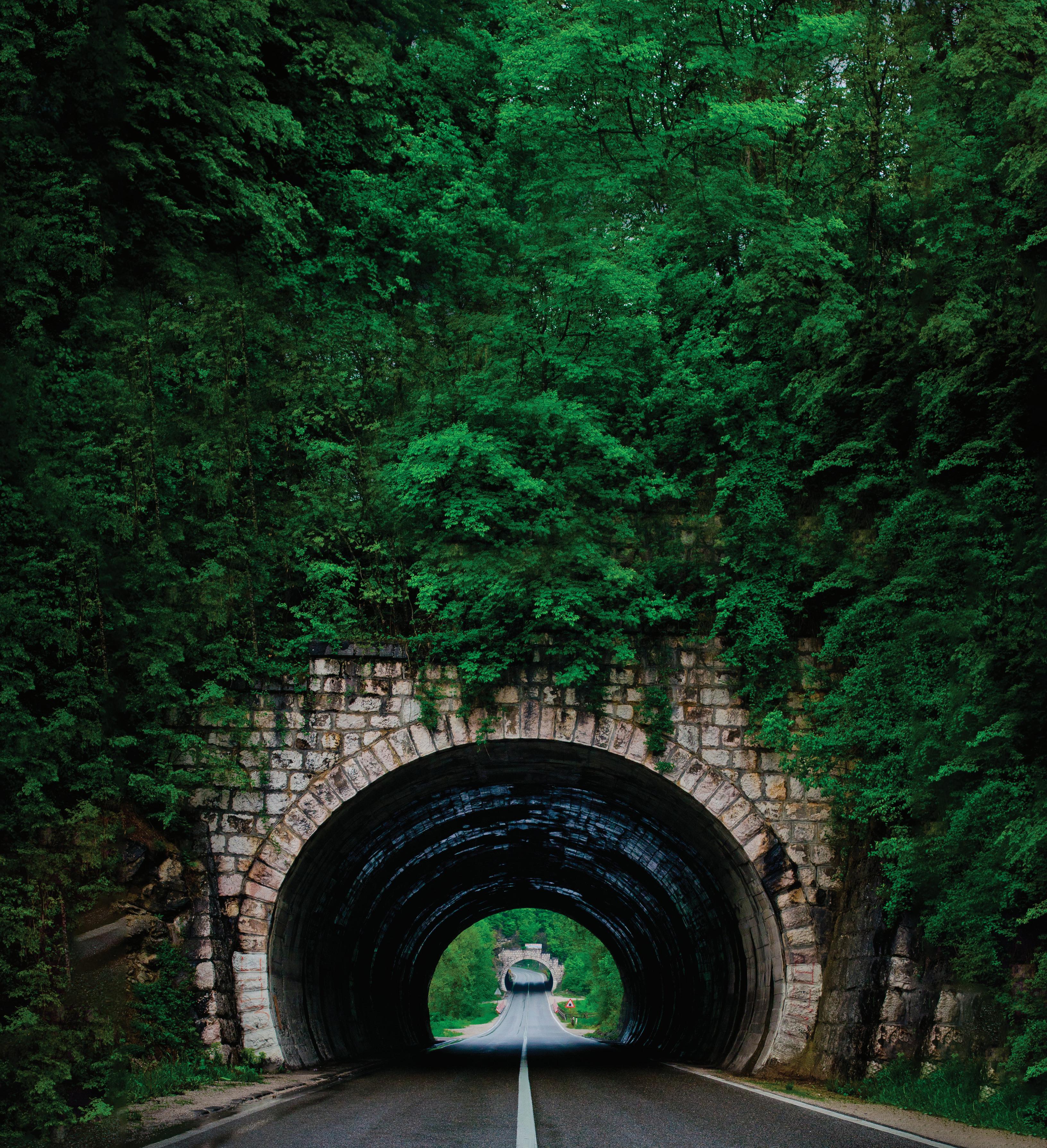

Beele Engineering provide the ultimate solution for fire resistance, smoke-proof and gas-tight requirements in tunnels and underpass environments whilst fully capable to deal with Dangerous goods / Hydrocarbon applications.

The detailed design and construction contract for the Monaro Highway Upgrade Project, at the Lanyon Driveinterchange, has been awarded –representing a $70 million investment in this major corridor.

The contract has been awarded to local Australian Capital Territory company, Woden Contractors, marking a significant milestone for the project which is expected to start in 2024.

This contract aims to make the highway safer, improve travel times and support freight movements.

The contract includes:

♦ A new southbound flyover of the Monaro Highway over Lanyon Drive (including 3m wide sealed shoulders)

♦ Upgrading of the highway road pavement from David Warren Road through to Sheppard Street (including 3m wide sealed shoulders)

♦ A new widened bridge on the northbound carriageway over Dog Trap Creek just north of Lanyon Drive

Another major package of works for the interchange is planned for 2024, subject to environmental and other approvals.

This will include the removal of traffic lights at the Alexander Maconochie Centre and extension of David Warren Road to Lanyon Drive, with a new roundabout and signalised intersection

connecting with a new Monaro Highway off-ramp and Sheppard Street.

The Lanyon Drive interchange is being designed to minimise the impact on existing native vegetation in the area.

The landscaping plans are set to be finalised during the detailed design phase and focus on local and native species, prioritising tree planting, water sensitive urban design and biodiversity conservation.

Detailed design will soon be finalised with major construction works expected to start in 2024 and take around three years to complete.

Previous works on the Monaro Highway Upgrade have already been completed as part of a program of works jointly funded between the Federal and Australian Capital Territory Governments.

This includes completed safety improvements and new overtaking lanes on the rural section of the Monaro Highway between Old Cooma Road and Williamsdale Road.

Extensive utility works, which started in January 2022, have also been completed near Lanyon Drive in preparation for the flyover, including relocation and protection of major watermains and telecommunication networks.

The relocation of two gas mains is expected to be completed in the coming months, which are necessary before main construction works get underway on the new Lanyon interchange.

Federal Minister for Infrastructure, Transport, Regional Development and Local Government, Catherine King, said that the Federal Government understands the importance of investing in infrastructure that supports growing populations, reduces congestion and improves travel times.

“This project will provide a major economic stimulus to the Canberra and Monaro region including an estimated 700 jobs to be created during the detailed design and construction phases,” Ms King said.

“Projects like this are important to not only keep local people employed and businesses running, but also to provide the region’s community with better infrastructure and safer roads into the future.”

ACT Minister for Transport and City Services, Chris Steel, said that the Australian Capital Territory Government is building the infrastructure its growing city needs.

“Our investment in projects like this supports our growing population, improves safety and the efficient movement of people and freight,” Mr Steel said.

“The Lanyon Drive flyover is part of a program of works to improve safety on the Monaro Highway by removing dangerous at-grade intersections and separating traffic turning across the highway, in and out of the Hume industrial precinct and New South Wales.”

Quest Apartment Hotels have quickly become a trusted staple for travellers, with the hotel group currently having 40 properties across New Zealand, with two additional properties in Christchurch scheduled to open in the next 12 months.

The two new locations are Quest on Cambridge, due to open on the 15th November 2023 and Quest on Kilmore, due to open June 2024.

Quest Apartment Hotels aim to be traveller’s home, or office, away from home, complete with separate living, dining and sleeping areas, workstations and a fully equipped kitchen and laundry facility. Allowing guests to cook their own meals, do their own laundry, and relax with plenty of space.

Apartments are serviced daily; in house services include valet laundry and dry cleaning, babysitting services, grocery delivery and charge-back with selected local restaurants.

Quest attracts guests staying for days, weeks or months at a time, with the combination of flexible accommodation and services making guests feel like they never left home.

Quest is perfectly equipped to cater for families attending conferences, with locations close to all major conference venues in New Zealand.

To find out more, go to www.questapartments.co.nz

Quest has turned 25, and there’s a lot to celebrate.

STAY IN THE HEART OF CHRISTCHURCH

Quest on Cambridge opening this November. Enjoy introductory rates from $135 per night for stays from 15th November 2023 to 14th January 2024*.

OUR SUSTAINABILITY QUEST

We’ve replaced almost all single-use plastic toiletries with dispensersremoving 3.68 tonnes of plastic out of circulation. We’re also recycling old soap bars into new ones together with Soap Aid.

Find out more at soapaid.org

*Rates start at $135 for a studio and $155 for a 1-bedroom apartment all booked via the Quest App and the Quest website. All bookings must be for stays between November 15th 2023 to January 14th 2024 to qualify for the introductory rate.

QUESTAPARTMENTS.CO.NZ

As the infrastructure sector continues to face a significant skills and labour shortage, we also face a very real solution — improving gender diversity.

Recently, I participated in a panel discussion at the 2023 Women in Construction, Engineering, and Infrastructure Summit.

Facilitated by Infrastructure NSW Acting CEO, Janine Lonergan, and joined by Australian Constructors Association CEO, Jon Davies, and Maree Bridger, Department of Infrastructure, Transport, Regional Development, Communications and the Arts COO, the conversation covered a range of issues relating to diversity in the workforce.

Panelists all made the critical point that increasing diversity is imperative to the success of any workforce, especially at a time when labour shortages are a significant issue.

It is a well-known fact that the infrastructure sector is facing a critical skills shortage.

From our Market Capacity research, we know that this year public infrastructure projects are expected to face a shortage of 226,000 skilled workers.

While this skills shortage is not unique to the sector, what is unique is the lack of diversity across its workforce.

Insights from our Market Capacity research also reveal that female representation across the construction sector stands at just 14 per cent. For on-site roles, this number falls dramatically to just two per cent.

This hasn’t changed in over a decade.

In the face of critical skills shortages, the infrastructure industry has tried to power through by demanding more of its workforce. Put simply, workers have had to go harder and faster to meet project demands.

The result has been excessively long working hours, stress, burnout, job dissatisfaction and poor mental health.

It’s a complicated landscape in a sector facing a number of challenges, but this approach has made the industry an undesirable place to work.

In fact, we know through early findings of our 2023 Market Capacity research that over 50 per cent of apprentices and trainees who completed infrastructure training in recent years did not enter their intended occupation, while 20 per cent did not enter any infrastructure-related occupation.

So how can gender diversity lead to better outcomes?

Importantly, it is the morally right thing to do. We should strive for equity and inclusion as a normal way of operating. But the benefits of increasing gender diversity within any workforce, especially for the infrastructure sector, are incredibly rich and rewarding.

We all know diversity encourages a flow of different ideas, fresh perspectives and creativity that can drive positive change and innovation. For the infrastructure sector, greater innovation will be necessary for its survival in the face of stagnating productivity.

There are also significant economic benefits for increasing diversity. According to the World Economic Forum, companies with more diverse management teams have reported 19 per cent higher revenue. In addition, improving gender pay is estimated to improve the global economy by a staggering 26 per cent.

Then there is the significant cultural change that can follow by introducing greater diversity, which ultimately benefits everyone.

In the current climate, a significant benefit for the industry would be an increased pool of people to draw from to alleviate the pressure felt by the skills shortage.

The methods for increasing diversity in the workforce are clear and already laid out for us by bodies such as the Workplace Gender Equality Agency.

Companies need to develop diversity and inclusion policies, strategies and plans, and address key issues such as flexible working arrangements, while also embedding equality, diversity and inclusion KPIs.

From Infrastructure Australia’s perspective, in our Delivering Outcomes Report, we advocate for the embedding of equality, diversity and inclusion objectives through each infrastructure investment as part of a holistic and consistent approach to achieving this need.

Governments at all levels also have a role to play in leveraging the procurement process for public infrastructure projects to achieve this as well.

This is one of the most powerful tools available to governments to drive effective change and guide the industry towards achieving greater diversity.

Changing the way projects are delivered and adopting more innovative working practices can also be a powerful way to attract and retain more diverse workforces.

One example is for companies to switch to modern methods of construction such as off-site manufacturing, which can ease the physical burden for workers and provide more flexibility in the hours needed to deliver a project.

These are just a few key examples of how gender diversity can be improved within the infrastructure industry.

Although, there is one more key element for enabling gender diversity to truly be able to grow within the infrastructure industry, which is through strong leadership.

Senior leaders in the sector should be trained to fully appreciate the challenges and benefits of equality, diversity, and inclusion, and learn the best practice methods for achieving effective outcomes.

There are some really strong examples of leaders taking charge to make a difference.

The experience of Alison Mirams, founding CEO of Roberts and Co, is a shining example; real and impactful solutions were implemented under her leadership.

Solutions such as a five-day work week, which fundamentally changed workplace flexibility, equality, and health and wellbeing outcomes.

By relentlessly advocating for diversity, challenging the status-quo and connecting to the practical issues impacting women in the workplace, real change was achieved.

Then there is the leadership of Mr Davies to set the goal of having 75 per cent of members achieve the Workplace Gender Equality Agency Employer of Choice citation.

At the end of the day, all avenues need to be explored and adopted to drive greater gender diversity within the infrastructure sector if collectively we are to make headway in addressing the labour gap and productivity challenges.

Traditional security can provide reliable protection for critical infrastructure by actively monitoring and preventing theft or damage, so long as security personnel are onsite. Smart security systems can provide eyes where traditional security cannot, offering a comprehensive service that ensures buildings and assets are not left vulnerable.

Security guards cannot always be onsite and traditional camera systems cannot always be installed, especially on remote or occupied sites, leaving opportunities for potential criminals to break-in and cause damage.

However, smart security technology can complement traditional systems to provide responsive surveillance and active deterrence.

Spectur provides smart security platforms that can not only detect danger, but also actively deter threats. With a variety of applications, Spectur’s systems can keep an eye on remote sites, prevent break-ins and theft, monitor ecosystems and protect communities.

When paired with intelligent surveillance that utilises cameras, sensors and artificial intelligence (AI) to gather imagery and information, smart security systems can offer an all-encompassing service to keep critical sites safe.

For nationally-significant infrastructure, security is vital to prevent theft, vandalism or damaged equipment that would cause interruptions and delays. Developers and managers cannot afford guards or cameras to miss anything, especially if that means adding weeks or months onto a multi-year project’s timeline in order to fix damage or replace equipment.

If security guards are not onsite at the time of a break-in, the intruders are often long-gone by the time any personnel turn up. Deploying Spectur’s security systems can help deter any potential intruders on large construction

sites by responding to intruders before they break-in.

Spectur’s camera systems are selfcontained, smart platforms capable of capturing imagery and responding in real-time to threats. With AI-enabled cameras and sensors, Spectur’s systems can trigger alarms, identify number plates, detect motion and send out alerts to create a digital fence that actively prevents criminal activity.

When a building is left unoccupied and there is no staff around to monitor the site, it can become a target for intruders. Spectur’s camera systems can provide another set of eyes while security personnel are away.

But not all intruders breaking into unoccupied buildings will be potential criminals. Sometimes they are homeless people seeking shelter or children looking for fun. Certain sites are dangerous for the general public to enter, which means deterring intruders not only protects the site but also keeps people safe from harm or injury.

Especially for homes or schools left vacant during the holiday season, when there is no one around, a smart security system can provide assurance that a building is always being monitored.

Remote energy assets are particularly vulnerable to theft and vandalism, being far away from urban areas, hard to access and regularly left unattended. For many locations, traditional security systems such as cameras and security guards are difficult to set up or employ, so many asset owners have no choice but to do nothing.

However, Spectur camera platforms can be set up anywhere, since they are wireless and solar-powered, making them ideal for remote locations where there is no wired electricity or internet connection.

Unlike traditional systems, Spectur’s systems have a built-in 3G/4G modem to transmit data and are powered by solar PV and battery storage. While a regular camera would need to be set up close to an asset or on the building itself in order to be connected to power and internet, a Spectur platform can be set up on the perimeter of a site, meaning intruders can be stopped before they even make it onto the property.

When there is no one else around and traditional security options are not possible, smart security systems offer an alternative to protect these critical remote energy assets.

Traditional security has its limitations, with cameras being unable to respond to threats and security guards not always being on patrol. But, when paired with smart security systems, the additional capabilities of AI, sensors, remote functionality and more can fill in the gaps to make sure no site is left unguarded and vulnerable.

For more information on boosting your security system with smart capabilities using Spectur’s solutions, call 1300 802 960 to talk to our team and find the right solution for your unique onsite challenges.

A new chapter of water security for 200,000 customers in southern Tasmania was written in September 2023, with TasWater officially opening its upgraded Bryn Estyn Water Treatment Plant (WTP).

The project, which was TasWater’s largest ever capital works project, was delivered on time and under its $243.9M budget.

The new water treatment plant will provide safe, clean, and reliable drinking water for generations to come.

TasWater Chief Executive Officer, George Theo, said the opening marked a major milestone for Greater Hobart.

“This was a landmark day for southern Tasmania,” Mr Theo said.

“The new plant is able to treat 160 million litres of water per day. It’s been designed for future population and economic growth, with the potential to be expanded to treat another 40 million litres of water per day if required.

“The project is a story of infrastructure, economic benefits, current and future jobs, protecting and enhancing the natural environment, and providing opportunities for Tasmanians. It is also the story of TasWater’s dedication to securing the best possible customer outcomes now and long into the future.”

TASWATER’S LARGEST EVER CAPITAL WORKS PROJECT

Located north of Hobart in the Derwent Valley, the Bryn Estyn WTP is Greater Hobart’s primary source of drinking water, providing around 60 per cent of the water supplied to southern customers.

Water from Bryn Estyn winds its way through 433km of water mains and into 145 reservoirs before reaching the taps of customers in Hobart, Glenorchy, Kingborough, Brighton, Derwent Valley, Southern Midlands, Sorell and Clarence.

The original plant was built in 1962, with capacity augmentations in 1972 and 1992, and construction work on the current upgrade commencing in mid-2021.

All major structures, buildings, electrical and mechanical installations are now complete, with the new infrastructure commissioned, and the plant officially opened at an event on 22 September 2023, which gained widespread media interest in Tasmania and beyond.

TasWater’s General Manager Project Delivery, Tony Willmott, said the scale of the project is unprecedented for TasWater.

“In the early phase of the works, 11,456 cubic metres of concrete was poured, 2,800 tonnes of reinforcing steel placed, and more than 93,000 cubic meters of soil was excavated,” Mr Willmott said.

“TasWater is currently delivering a planned 10-year, $1.84 billion capital investment program for completion in the financial year 2025-26. The program is delivering important customer and environmental outcomes for the benefit of all Tasmanians.”

“During construction the project employed around 1500 people directly, and 500 indirectly,” Mr Willmott said.

“At its peak, around 150 people were working on site every day, generating benefits for Tasmanian businesses across the state.”

The Bryn Estyn project was delivered by TasWater’s Capital Delivery Office (CDO), an alliance with UGL Limited and CPB Contractors, along with their sub-alliance partner WSP, which will continue to deliver TasWater’s accelerated Capital Works Program through to July 2025.

It is a model that continues to directly support the Tasmanian economy, with more than 80 per cent of the total value of CDO packages being awarded to Tasmania-based suppliers, providing a significant economic boost for the local civil construction sector and its supply chain, growing the capability of the local contractor market for future projects.

TasWater’s Head of Water and Environment Services, Fran Smith, said the upgrade expanded the capacity for the organisation to deliver greater volumes of high-quality, safe drinking water for Hobart.

“To be able to treat and deliver 160 million litres of water every day, with every litre meeting the Australian Drinking Water Guidelines, is not a small task,” Ms Smith said.

“Each drop of water that has passed through Bryn Estyn has been subjected to a treatment process that includes filtration, ozone, absorption using activated carbon, chlorination, and now Ultra Violet disinfection for an extra layer of treatment.

“Just last year alone, across the state we undertook 273,000 tests to ensure Tasmanians could turn on the tap with confidence knowing their water is absolutely safe to drink, one test every two minutes.”

Mr Theo said TasWater was all about a customerfocused future.

“TasWater has a range of initiatives underway as we ramp up our customer and community focus and continue our journey to being the best service provider in Tasmania. The project takes us one step closer to realising our strategic vision ‘to unlock the full potential of water’ for a thriving Tasmania.

“We are proud of what TasWater is delivering, and the Bryn Estyn WTP is a prime example. While it is a story of a vast infrastructure project, it is also a human story for so many people, not least our customers, who will receive the benefits of the Bryn Estyn WTP upgrade for decades to come.”

In our home lives, we understand the value of maintenance. We wash our cars, check our gutters, vacuum our floors and look after our health. The same care and maintenance is applicable to the buildings we protect through waterproofing, because, when certain areas are neglected or left unchecked, the consequences can be damaging and costly.

Colin Picton, Fosroc ANZ Product Segment Specialist for Waterproofing and Joint Sealants, emphasises the importance of regular maintenance, and prompt rectification of any damage.

"Maintenance plays a crucial role in maximising the longevity and performance of waterproofing products," Mr Picton said.

"Keeping exposed areas clean makes it easier to check for cracking caused by movement or damage from falling debris.

"Checking for, and clearing, a blocked drain is far more effective and financially palatable than spending big money on re-waterproofing and the ensuing disruption it causes. Following a planned cleaning and maintenance program not only keeps the structure looking good, it will help avoid unexpected costs moving forward."

When it comes to waterproofing solutions, Fosroc ANZ's Nitoproof systems provide trusted, world-class results.

The liquid-applied range of membranes and topcoats, together with Nitoseal sealants, are made to withstand the toughest Australian conditions, and preserve the durability of the underlying structures it protects.

FOSROC’S TOP MAINTENANCE TIPS

Stay ahead with regular inspections

Create and action a scheduled maintenance plan in accordance with AS4654.2 2012. Pay close attention to joints, corners and terminations, and look for membrane cracking and blistering, bald spots or any other wear and tear. Storm damage from hail or fallen branches and debris can block drains. Record the inspection, including taking photographs.

Regular cleaning is essential for preserving the effectiveness of the Nitoproof system. Exposed to the elements, the membrane may accumulate dirt, debris, or other contaminants

that could compromise its performance. Clean coatings with a neutral pH cleaner or detergent and apply to the surface using a soft bristle broom. Rinse off thoroughly with clean water using low pressure spray. In coastal areas more regular cleaning may be required to prevent the build-up of salt contamination, every six months is recommended.

Keeping drains clear and functional prevents water accumulation, which can cause additional stress on the waterproofing membrane. Checking regularly, especially after storm or hail events will reduce the risk of leaks or structural damage.

Timely repairs for lasting performance

In the event of accidental damage or unforeseen circumstances, timely repairs are crucial for sustaining the performance of the Nitoproof waterproofing membrane. Before undertaking any repairs ensure the underlying cause has been identified and addressed. Any necessary repairs or maintenance should be carried out promptly by a suitably qualified contractor.

Commitment to waterproofing success

Regular inspections, proper cleaning, optimal drainage, and timely repairs are the cornerstones of effective maintenance. "Regular and comprehensive maintenance practices optimise the durability of any waterproofing system," Mr Picton said.

"By incorporating these practices into your routine, you can safeguard your structure, avoid costly repairs, and have peace of mind knowing that your waterproofing system is well-maintained."

The Australian infrastructure landscape is undergoing a profound transformation, marked by comprehensive policy reviews, and a noteworthy shift from transport infrastructure to renewables, electricity transmission, social infrastructure (such as water and hospital) and defence (in the north).

This era of change has left Catherine King, Minister for Infrastructure, Transport, Regional Development, and Local Government, contemplating two pivotal reports: the Infrastructure Investment Program (90 day) Review and the National Partnership Agreement (NPA) on Land Transport Infrastructure Projects

The 90-day Review, executed by an experienced trio comprising Mike Mrdak AO, Clare Gardiner-Barnes, and Reece Waldock AM, sets the stage for intense consultations between the Federal and State/Territory Governments.

Those negotiations are focused on three central themes: productivity, liveability, and sustainability. The liveability dimension is a nod to Prime Minister Anthony Albanese's urban vision, evaluating infrastructure based on its impact on the quality of life for people and communities.

The government's response to this 90-day review is eagerly anticipated by industry, and it's expected the response will coincide with the release of the Mid-Year Economic and Fiscal Outlook in early December.

The prevailing messaging from both is expected to emphasise fiscal and economic challenges, potentially necessitating a recalibration of the infrastructure agenda. Brace for funding cuts or delays for numerous infrastructure projects, considering an eye-popping $33 billion overrun in the infrastructure pipeline.

In the meantime, while these reviews are underway, the infrastructure spending tap has been turned off, causing many engineering consulting firms to feel the sting. Anecdotal evidence is mounting of large-scale redundancies by major consulting firms, which, in turn, will have a ripple effect on contractors who may find themselves bidding for a smaller pool of contracts up to a year behind schedule.

While this is all underway, Jane Halton AO PSM, a former senior public servant, was entrusted with overseeing the Independent Review of the NPA on Land Transport Infrastructure Projects, a critical mechanism through which the Commonwealth invests in land transport infrastructure in tandem with states and territories. As the NPA approaches its expiry date on 30 June 2024, the findings from this review will serve as the blueprint for negotiations surrounding a new Land Transport National Partnership Agreement.

This renegotiation will zero in on the project commitment and approval process, with a spotlight on administrative efficiency.

The 80:20 federal/state funding model in regional Australia is almost certain to be abolished given it is viewed by some in the government as a mechanism to favour regional electorates.

As part of the NPA Review, organisations like the Australian Owned Contractors Association and the Civil Contractors Federation are vigorously advocating for the government to meet its commitments in the Buy Australian Plan, to foster a more accessible and level playing field by implementing project package caps of $500 million.

The Buy Australian Plan aims to boost industry productivity and competitiveness by incentivising states and territories to embrace a set of rules, promoting opportunities for local mid-tier firms in bidding for significant infrastructure projects. One key component involves the subdivision of contract sizes to ensure they do not exceed $500 million in value.

There's also a pressing need for both industry and government to confront the monumental task of decarbonising transport. In 2020 the transport sector contributed around 18 per cent of Australia’s emissions, predominantly related to road-based transport, and a staggering 70 per cent of Australia's greenhouse gas emissions are tied to infrastructure.

The Commonwealth is resolute in its commitment to reducing greenhouse gas emissions, and while it's almost a given that Australia will miss its target of a 43 per cent

reduction below 2005 levels by 2030, it remains committed to the goal of net-zero emissions by 2050.

In response, the Commonwealth is crafting a Transport and Infrastructure Net Zero Roadmap and Action Plan to guide the reduction of transport emissions.

Furthermore, the Commonwealth is on the cusp of releasing an Infrastructure Policy Statement, aimed at establishing a comprehensive framework for both the industry and the government to navigate this new infrastructure landscape.

Simultaneously, the focal point of Australian infrastructure activity is shifting significantly from transport infrastructure to renewables, electricity transmission, social infrastructure and defence. This transformation is expected to be most pronounced in regional Australia, giving rise to a commensurate demand for a skilled workforce.

The latest Infrastructure Partnerships Australia Pipeline Report spanning from January 2022 to August 2023 highlights a substantial surge in energy-related expenditures, surging from $44.9 billion to $116.7 billion.

In contrast industry research and forecasting company, Macromonitor has predicted that while Australian major transport construction spending is at over $23 billion per annum, that will now start to tail off.

From a national perspective, the zenith of transport construction has been reached, with attention now firmly shifting towards renewables, transmission, social infrastructure and defence.

The Commonwealth has unveiled its monumental $20 billion Rewiring the Nation program, aimed at access to clean energy while striving to meet stringent emissions reduction targets.

A pivotal element of this initiative involves the construction of 10,000 km of new transmission lines, promising a substantial surge in infrastructure spending for regional Australia, driven by the renewable and transmission sectors.

While there are significant social license issues for transmission pending or currently in play, this sector will be a major contributor to regional employment and economic growth.

The realm of infrastructure is perpetually dynamic and exciting. However, the upcoming years promise not only a transformation in funding decisions but also a significant shift in the very nature and objectives of infrastructure development.

Michael Kilgariff is a former CEO of Roads Australia and Managing Director of the Australian Logistics Council. In these and previous roles, he has developed a reputation for building strong working relationships across industry and government, with the aim of supporting and achieving outcomes that are mutually beneficial to industry, government and the community.

Engineered stone (a.k.a. quartz or artificial stone) is a popular material widely used for stone benchtops in kitchens and bathrooms. However, recently this has come under scrutiny due to its health risks that it poses for workers, with the Federal Government considering a ban of the material.

The high levels of crystalline silica found in engineered stone pose a severe threat to the health and well-being of workers who handle it. These invisible silica dust particles are 100 times smaller than a grain of sand, so can travel deeply into your lungs where they wreak havoc – causing the lung disease called silicosis.

Recently, there has been an explosion of cases of silicosis in tradies, especially in stone benchtop workers. Silicosis is also a risk when working in any workplace which creates silica dust, such as excavation, mining, quarrying and mineral processing, tunnelling, construction, concrete or masonry, and pottery making, just to name a few.

Silicosis is the oldest occupational lung disease on record and is entirely preventable. More than 275,000 Australians are now at risk of cancer and lung disorders caused by silica exposure – that is, more than the entire population of Hobart and Launceston combined.

Curtin University researchers have shown that workers in trades have a 37 per cent risk of developing silicosis in later life. Monash University research published in June 2023 found that 28 per cent of Victorian stone benchtop workers had silicosis, and 21 per cent had advanced silicosis.

In the interests of protecting lives and ensuring workplace safety, a ban on engineered stone is a critical step towards a healthier and safer environment for all.

Engineered stone is produced by compressing ground stone such as crystalline silica and combined with resins. The crystalline silica content in stone bench tops can vary widely depending on the type of stone used.

Engineered stone benchtops can contain up to 95 per cent crystalline silica. Natural stone such as granite may contain from 20 to 60 per cent. It is the respirable crystalline silica released into the air which causes silicosis – no airborne silica dust, no silicosis.

Silica dust, generated during the fabrication and installation processes using engineered stone, poses a grave danger to workers. Silicosis is a debilitating and potentially fatal lung disease. Silicosis is irreversible, and its effects can be devastating, robbing workers of their lives and cutting short their careers.

The importance of prioritising workplace health and safety cannot be overstated. While measures such as dust control and personal protective equipment can help mitigate risks, they are not foolproof.

Despite reduction in dust levels and guidelines and regulations having been revised, instances of non-compliance or inadequate implementation are still common, leaving workers vulnerable to the dangers of silica dust exposure. A ban on engineered stone would eliminate this risk altogether in exposed workers, ensuring the highest level of protection for these workers.

Silicosis is silently progressive, usually only becoming noticed years after exposure to silica dust. Workers may not realise the severity of their condition until it is too late.

At TSANZ, we strongly advocate for a ban on engineered stone in Australia. By banning engineered stone, we have an

opportunity to prevent this silent suffering and protect the lives and livelihoods of many workers who are at risk.

Our members are the clinicians who diagnose and treat tradies with silicosis, and they tell us that this is the first and most important step to protect the workforce. Our tradespeople are getting sick, are forced out of employment, and die – for going to work every day to provide for themselves and their families, and that is simply not acceptable to us.

As a society, we have a moral and ethical responsibility to prioritise human lives over profits. While engineered stone has gained popularity for its aesthetic appeal and durability, the toll it takes on the health of workers cannot be ignored. Can your conscience cope knowing your faux stone benchtop contributed to a child or spouse losing their parent or partner?

By implementing a ban, we, as a society, send a strong message that the well-being of individuals should never be compromised in the pursuit of commercial gains or aesthetic appeal.

Advocating for a ban on engineered stone does not mean sacrificing progress or design options. It presents an opportunity to promote the adoption of safer alternatives that do not pose the same health risks.

The development and utilisation of materials which do not pose a risk of lung disease is possible and can create a safer work environment without compromising industry growth or aesthetic choices for consumers.

One of our trusted colleagues, Kate Cole, who is a certified Australian occupational hygienist, researcher, and thought leader in this area, has some great educational resources. Some examples of alternative materials she recommends include stainless steel, timber, and laminate. Stainless steel and timber (depending on the type) are highly durable materials, while laminate is a great low-budget option for homeowners who like to upgrade their kitchen as trends change.

Silicosis often affects individuals in their prime working and tax paying years, thus creating economic dependency

for workers who may have to rely on e.g., unemployment or disability benefits.

The treatment and management of silicosis requires specialised medical care, including diagnostic tests, medications, and sometimes lung transplantation. These expenses contribute to the overall healthcare burden and can strain healthcare systems. Besides being good public policy, it is in the Federal Government’s financial interest to address this issue head on and prevent rather than treat the disease.

Tradies who receive a silicosis diagnosis should consult with their employer and lawyer as soon as possible. It’s important that workers get the support and compensation they need and are entitled to, but workers’ compensation processes need to be followed.

We encourage any person who is concerned that they are suffering from a respiratory condition and who interacts with materials containing silica to have conversations with both their employer and legal representation as early on as they can.

Banning engineered stone is an essential step to protect the lives and health of workers who handle this material. Silicosis is a completely preventable disease and should not be occurring in the 21st century.

By taking decisive action, we can ensure that no worker suffers these devastating effects. By advocating for a ban, we affirm our commitment to workplace health and safety, responsible decision-making, and the wellbeing of our workforce and their families. Let us prioritise human lives above all else and work towards creating a safer and healthier future for all workers.

Vincent So is CEO of The Thoracic Society of Australia and New Zealand (TSANZ). TSANZ is the only health peak body representing a range of professions (medical specialists, scientists, researchers, academics, nurses, physiotherapists, students, and others) across various disciplines within the respiratory/sleep medicine field in Australia and New Zealand.

As a country known for its thriving coffee culture, it’s no surprise that Australia generates 75 million kilograms of ground coffee waste every year. Most of this ends up in landfill, contributing to greenhouse gas emissions and exacerbating environmental degradation. To combat this, a team of RMIT University researchers are on a mission to transform discarded coffee grounds into a valuable resource that can support a more sustainable construction sector.

The construction industry is one of the largest consumers of natural resources and a significant contributor to carbon emissions, making circular practices crucial for mitigating the impacts of resource depletion and climate change. From the repurposing of end-of-life work apparel to freeway noise walls made of plastic waste, circular initiatives are becoming increasingly prevalent across the sector.

Due to this need for more sustainable options in the sector, a team of engineers from RMIT University have published a study, Transforming spent coffee grounds into a valuable resource for the enhancement of concrete strength, that offers a new way to utilise coffee grounds.

Lead author, Dr Rajeev Roychand, said the motivation behind the research was reducing some of the 6.87 million tonnes of organic waste that ends up in Australia’s landfills per year, which contributes to three per cent of the country’s greenhouse gas emissions.

“Our research group discussed shifting our focus to diverting this waste from landfills and developing innovative solutions to transform waste into a valuable resource for different applications,” Dr Roychand said.

“Incidentally, this conversation happened over a cup of coffee in our team meeting. That’s why we decided to start with coffee grounds.”

The developed technique uses a low-energy process without oxygen at 350 degrees Celsius to turn used coffee grounds into biochar, which can then be used to make concrete 30 per cent stronger.

As the first study to prove that waste coffee grounds can be used to improve concrete, it has not been without its challenges.

“Organic waste in its raw form is detrimental to the concrete strength due to the organic compounds hindering the hydration reaction of cement,” Dr Roychand said.

“They need to be converted into biochar to make it compatible with concrete. But even to make biochar the process parameters are highly critical to deliver the best performance in its concrete applications.

“We started with raw coffee waste, which saw a significant reduction in concrete strength. This is because coffee waste leaches out organic compounds that hinder cement reaction, thereby negatively impacting its strength development. The team then worked on a method to break these organic compounds while preserving the carbon content, for that we used the pyrolysis process.”

Typically, pyrolysis – heating organic waste in the absence of oxygen – is carried out at higher temperature for the efficient thermal decomposition of organic waste. However, a key focus of the study was minimising energy use.

“We started with pyrolysing at a temperature of 500°C,” joint lead author Dr Shannon KilmartinLynch said.

“This saw significant enhancement in concrete strength compared to that of the raw coffee grounds in concrete, but it was still lower than concrete that does not contain any coffee waste.

“Since our focus was to minimise the energy consumption, we went for a lower pyrolysis temperature (i.e., 350 °C) and hoped that the lower decomposition could potentially help in improving the properties. It was a blessing in disguise. To our excitement, we noticed an improvement in concrete strength by almost 30 per cent.”

While the team’s research is still in the early stages, coauthor Dr Mohammad Saberian said the study is receiving plenty of attention from those who want to collaborate and translate the research into field applications.

“We are starting with field trials in collaboration with a local council and a few construction companies and we are hoping

Incorporating biochar into concrete offers several benefits. By significantly increasing the strength of concrete, the amount of cement content required can be reduced if needed. Furthermore, this waste to resource transformation creates the potential for diverting this waste from going to landfills in concrete applications, promoting sustainability and a closed-loop circular economy.

50 billion tonnes of natural sand is used in construction projects globally each year, with a considerable portion of this used in making concrete. This level of sand extraction has a significant impact on the environment, including habitat destruction, erosion, and disruption of river ecosystems. Coffee biochar could replace a portion of the sand that is used in concrete production, reducing that environmental impact.

Group Leader, Professor Jie Li, said, “The construction industry relies on continuous mining of finite natural resources to meet the ever-growing demand for the infrastructure development for the growing population.

“To keep this industry sustainable, we need to grab all innovative solutions that promote circular economy without compromising the mechanical and durability properties of the structural elements.”

to expand these trials internationally. We would be very happy to collaborate with local, state, and federal governments and construction companies willing to translate this research into field applications in different parts of the world.”

The construction industry has a long way to go until sustainability is fully integrated into everyday processes and projects. However, initiatives such as the recycling of organic waste, can support the sector to reduce its environmental footprint and drive sustainability forward.

The concrete industry is particularly well-positioned to contribute significantly to increasing the recycling of organic waste.

Dr Roychand said the research team will continue working on a range of waste materials and developing optimum process parameters for all forms of organic waste.

“There’s more groundbreaking research in the pipeline, so stay tuned.”

‘Transforming spent coffee grounds into a valuable resource for the enhancement of concrete strength’ is published in the Journal of Cleaner Production (DOI: 10.1016/j.jclepro.2023.138205).

Across the world, infrastructure projects wrestle with complex geotechnical challenges that quietly wait to trip up even the best planned road, tunnel, embankment, and foundation (plus many more), and it's not getting any easier for those in charge of these essential infrastructure projects.

Ground conditions can be unforgiving, deadlines unyielding, budgets restricting. Yet with any infrastructure project, geotechnical engineers are still expected to deliver an almost clairvoyant ability to predict how the ground will behave under certain conditions, and what that might mean for the asset during construction and throughout its life.

Engineers must assess ground behaviour and grasp the risks of settlement and impacts on neighbouring infrastructure, while facing the pressure of increasingly tough time and cost constraints. They have to feel confident they’ve got it right – now and in the days to come – and deliver a geotechnical analysis model able to support current and long-term decision making.

That means having tools they can trust to effectively see the future of the ground beneath their feet, and the asset built upon it.

In September PLAXIS celebrated 30 years of actively supporting the world’s geotechnical engineers, and giving them that ‘superpower’ (well, at least making it a lot easier).

In that time the software has developed from its core purpose as a user-friendly, finite element package, to become a resourceful, all-round companion for geotechnical engineers making critical, day-to-day decisions on the analysis of soil, rock and associated structures.

For example, in Australia, civil engineering consultancy WSP were faced with sand-capped, highly compressible peat swamp during the construction of a $165 million road extension project in Perth.

WSP Australia’s Principal Geotechnical Engineer, Shan Tom Wong, said, “If the approach embankments and bridge ramps were built without ground improvement, the peat would continue to settle significantly.”

However, the solution of driving concrete pillars through the peat to the stratum below called for 160 different design combinations to be analysed – an enormous task. By

automating the PLAXIS analyses, all 160 could be powered through easily, swiftly and efficiently, rather than doing them one-by-one, inviting errors and delays.

In a very different situation, the Laohutai mine in China faced the challenge of heavily laden mine trains inducing strong vibrations as they passed mine slopes and underground shafts.

Product Manager, Geotechnical Analysis, Sequent, Miquel Lahoz, said, “Safety was paramount with the possibility of slope or tunnel failure. “

Using PLAXIS 3D the Laohutai research team created a complex numerical model to simulate interactions between the rail track, slope, tunnels and underlying geology, and were reassured the mine could continue safely.

“Their predictions were validated with measurements taken on site and found to be stable with a safety factor of 1.2, well above the Chinese mining standard threshold,” Mr Lahoz said.

Unsurprisingly, the team said they valued PLAXIS for “its solid theoretical base, user-friendly interface, and strong logic for analysis in almost any geotechnical engineering field”.

Over the years, increasingly advanced iterations of PLAXIS have added creep or flow-deformation coupling through consolidation, simulating complex hydrological conditions, and determining how earthquakes or traffic flows can impact ground stability.

In addition to extensive geotechnical modelling capabilities, PLAXIS’ command-driven API has also been key in connecting it to other software, easily exchanging data, and automating model creation and the processing of results.

PLAXIS’ vision for the next 30 years revolves around several key pillars, including advancements in constitutive modelling and automated parameter determination, rock engineering, offshore geotechnical engineering, seamless integration with geological models, data-driven design and cloud computing. In short, it is and will keep constantly growing and evolving.

Now, three decades on from its original development at Delft University of Technology, PLAXIS fits seamlessly within Seequent’s broader range of products to boost interoperability and enhance communication within the industries it supports.

For over 30 years, PLAXIS has been trusted by geotechnical experts as the industry standard to perform advanced finite element analysis to solve common and complex geotechnical problems in soil and rock.

PLAXIS is more than just software; it’s a bridge connecting geotechnical engineering with a transparent approach to how structures interact with the subsurface, enabling better decision-making and ultimately ensuring the success of complex projects.

with a growing population

Over five million people live in Melbourne, with that number growing daily. As a result, the city’s sewerage infrastructure must be upgraded and expanded regularly to keep up with growing needs. This is why Melbourne Water’s tunnel boring machine – named Lucey – has been working hard underneath the Yarra to build the city’s eagerly awaited new Hobsons Bay Main Sewer.

The Hobsons Bay Main Sewer transports approximately 30 per cent of Melbourne's wastewater, sending it to the Western Treatment Plant, with the sewer main constructed in the 1960s and quickly approaching the end of its service life.

In order to make the necessary upgrades to keep it operating into the future, the Hobsons Bay Main will need to be temporarily shut down. Unfortunately, the needs of Melbourne’s waste network can’t be put on hold so easily.

To ensure the city continues to flow smoothly, Melbourne Water is funding a $206 million duplication project to reproduce the sewer, which will support the network while the original main is upgraded to modern standards.

Early works for the project began in 2021 and construction is expected to be completed in mid-2024.

Tunnelling works began in August of 2023, with Melbourne Water’s TBM, Lucey, operating at depths of between 24.5m and 27m below the surface of the Yarra, alongside the original sewer main.

The new 670m Hobsons Bay Main Sewer will stretch from Westgate Park, Port Melbourne to Scienceworks in Spotswood, under the Yarra River.

Melbourne Water’s Managing Director, Dr. Nerina Di Lorenzo, said that this major project forms part of a broader Melbourne Water capital infrastructure program that will enhance the reliability of the city’s sewerage network and services for the benefit of Melburnians today and for generations to come.

The Victorian Government, Melbourne Water, John Holland and Museums Victoria have all joined together to collaboratively deliver this significant upgrade project.

Dr. Lorenzo said that Melbourne Water is working hard to ensure that business as usual can continue for its neighbours, like Scienceworks and Grazeland, while considering the needs of the community and the impact these works have on everyone.

“We’ve developed a strong partnership with our delivery partner, John Holland. Our partnership extends over three years on this project, but has been ongoing as our long term partner on the Major Capital Delivery Water Framework,” Mr Le said.

“Our commitment to safety is of utmost importance to both companies. On the ground we hold joint safety forums, and mental health and wellbeing toolboxes, and these serve as a platform where we mutually learn from each other’s experiences, refining our practices for a safer work environment.”

John Holland Project Manager, Lucas Martinez, said that John Holland’s long-standing relationship with Melbourne Water spans over 20 years, including multiple tunnelling and deep sewer projects.