Issue 8 September 2018 ROAD - RAIL - AIRPORT - PORT - URBAN - UTILITY

DESIGN PHILOSOPHY OF THE MODERN TUNNEL

THE LOGISTICS OF AUSTRALIA’S BLUE HIGHWAY The technologies DISRUPTING ASSET MANAGEMENT

ROAD RAIL TUNNEL UTILITY VERMEER Vermeer and the Vermeer logo are trademarks of Vermeer Manufacturing Company in the United States and / or other countries. © 2018 Vermeer Australia. All Rights Reserved. CONSTRUCTION EQUIPMENT SOLUTIONS FOR AUSTRALIA’S INFRASTRUCTURE INDUSTRY / VermeerAustralia VERMEER.COM.AU | 1300 VERMEER

AS AUSTRALIAN INFRASTRUCTURE PROGRESSES, WE’RE PROUD TO PARTNER WITH THE CONTRACTORS THAT ARE LEADING THE WAY FORWARD.

8,313

ABN: 36 426 734 954 PO Box 1763

Preston South VIC 3072

P: (03) 9988 4950

F: (03) 8456 6720

monkeymedia.com.au info@monkeymedia.com.au infrastructuremagazine.com.au news@infrastructuremagazine.com.au

Editor Jessica Dickers

Associate Editors

Lauren Cella

Charlotte Pordage

Journalists

Elisa Iannunzio

Lauren Butler

Digital Marketing Manager

Sam Penny

Business Development Manager

Rima Munafo

Marketing Assistant

Helena Brace

Production Coordinator

Erin Foster

Senior Designer

Alejandro Molano

Designer

Aileen Ng

Publisher Chris Bland

Managing Editor

Laura Harvey ISSN:

EDITOR’S WELCOME

As of Tuesday 7 August at around 11pm, Australia’s population ticked over 25 million, according to the Australian Bureau of Statistics’ Population Clock. This milestone has people concerned that if the population keeps increasing this rapidly, infrastructure in major cities won’t be able to cope.

The need to take a closer look at how we plan, deliver and use infrastructure across the country to deal with this increased pressure has already been discussed at length over the last few years. Now the emphasis needs to be placed on more integrated infrastructure planning, in particular for our transport infrastructure, and using the technologies that we have available to start overhauling current and future infrastructure.

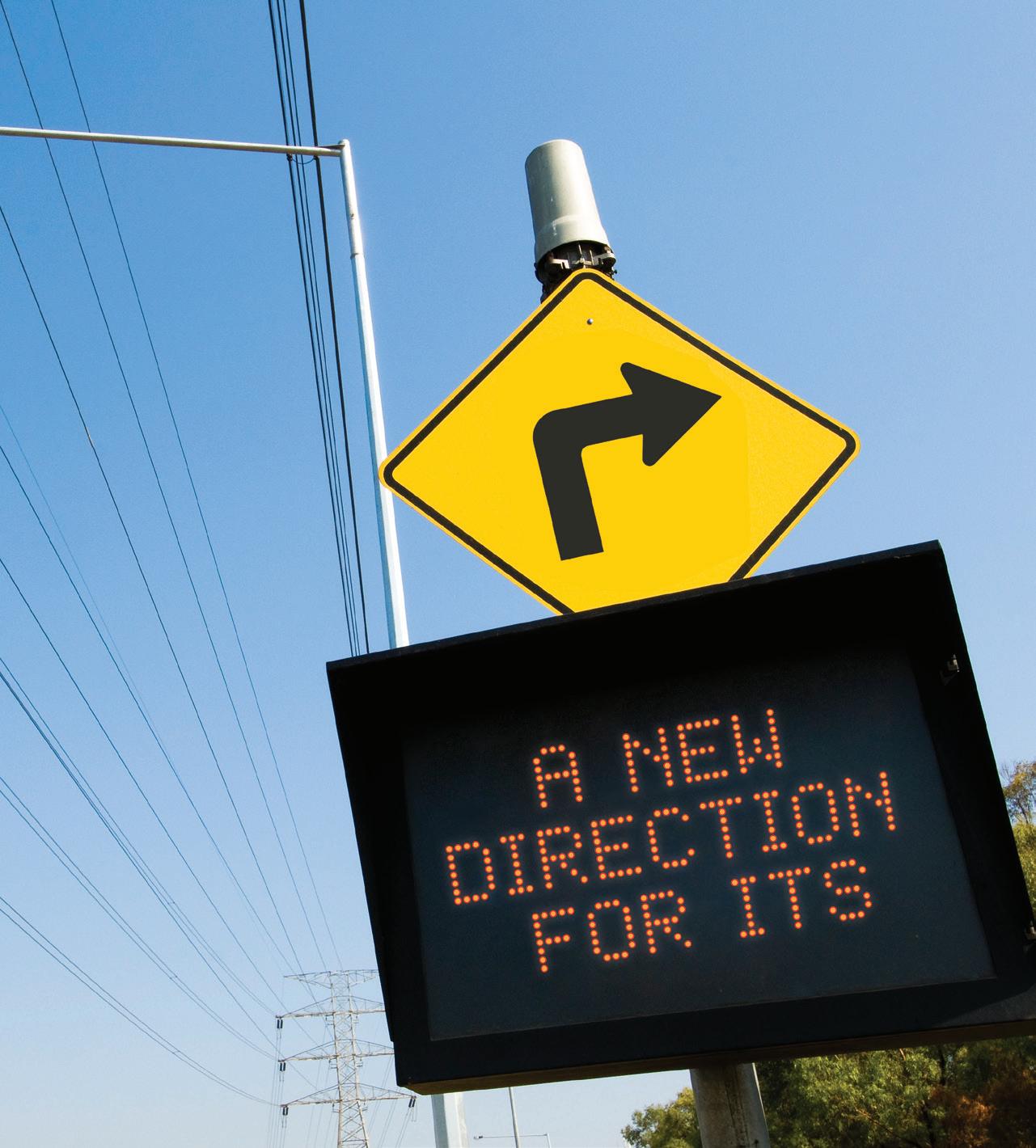

Smart cities, intelligent transport systems (ITS), information and communication technology – we now have the ability to connect and enable communication across assets to give us incredible volumes of data. This has the potential to fundamentally change the way infrastructure is planned, designed and built.

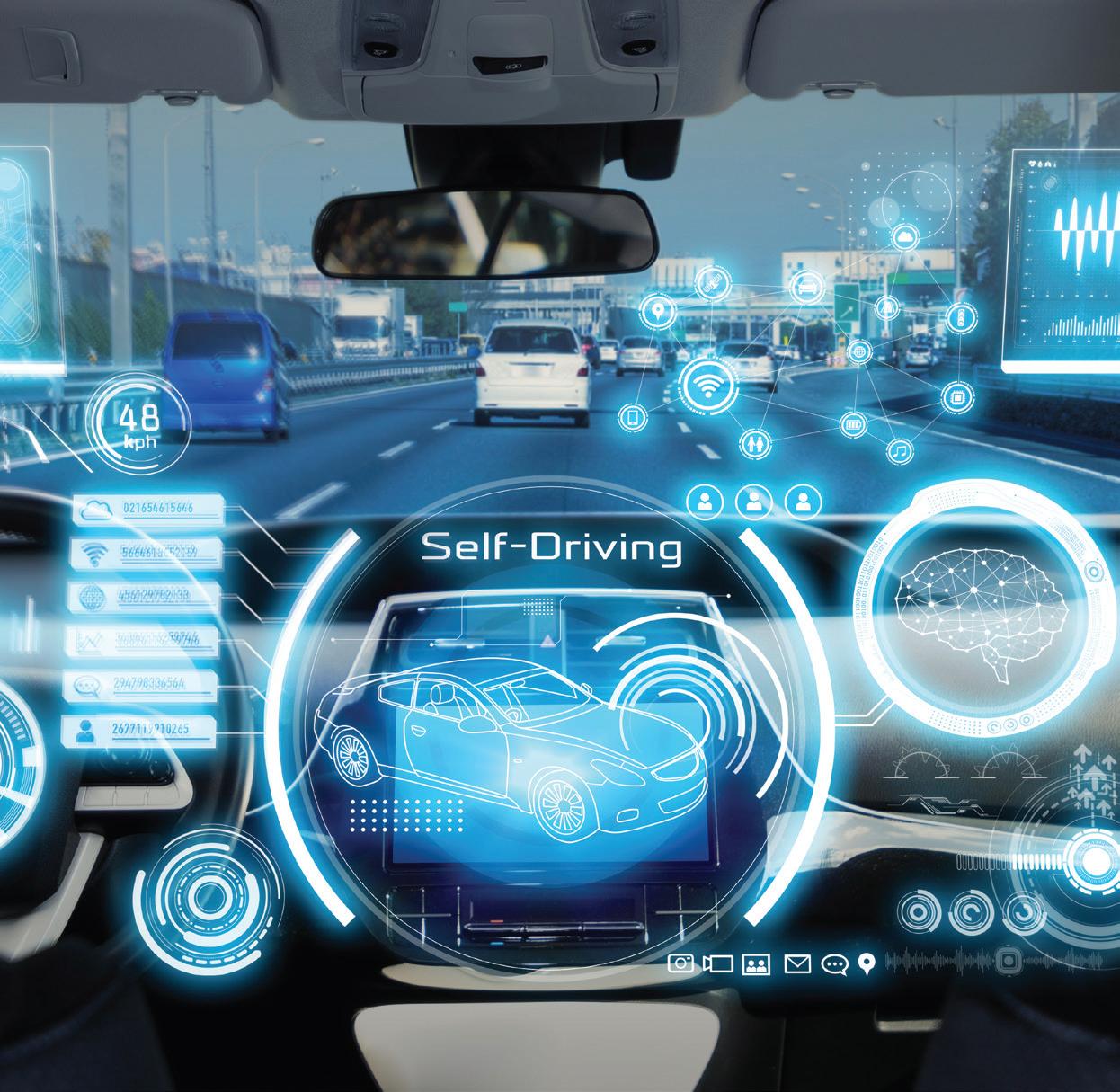

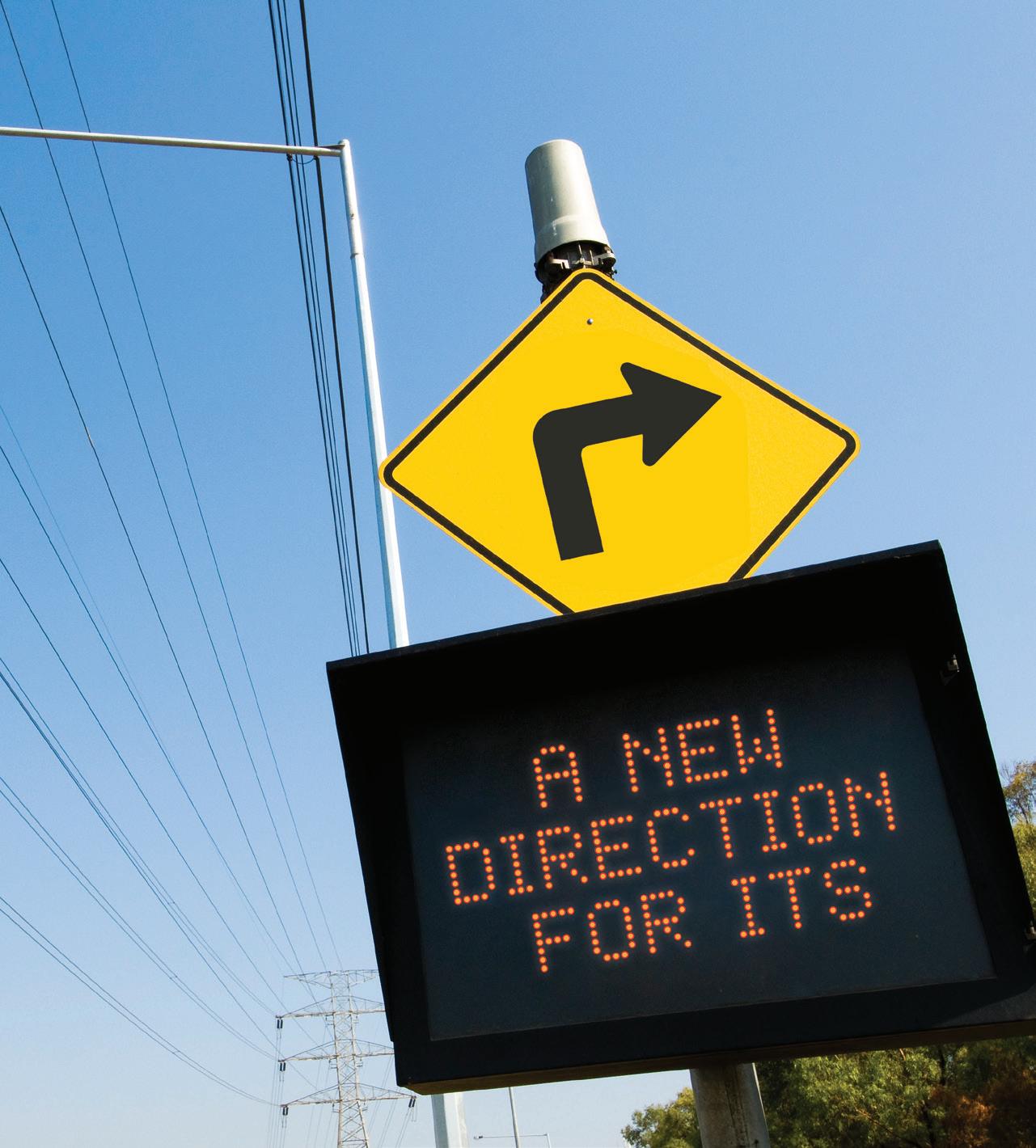

An increasing population will only add to the congestion on our cities’ roads, but ITS infrastructure, and the uptake of driverless and electric vehicles, could help to minimise this. Intelligent installations, from variable speed limit and electronic message signs, to CCTV cameras and vehicle detection loops, all increase communication to drivers, helping them make more informed decisions.

If, or when, driverless vehicles become a common sight on our roads, they could dramatically reduce congestion by having less cars on the roads. Their uptake could also change the requirements for road infrastructure, including the implementation of

charging infrastructure. There is also talk of hydrogen fuel cell vehicles potentially improving the heavy vehicles and freight sector.

Technologies could even be implemented to change the way Australians pay for roads by assessing exactly which roads people use and how often.

This issue of Infrastructure looks at the current and future possibilities for ITS and other technologies, including robotics, to get a better understanding on their impacts across all infrastructure, from roads, to energy and freight.

While some of these might be a long way off, integrating current technologies into our infrastructure and making data-based planning decisions is needed to help the infrastructure sector better prepare for future challenges like population growth.

While politicians like to make big announcements and promises to build flashy projects, there’s a lot of improvements to current infrastructure that, while they might not be as exciting, could have even bigger impacts on the way Australians move around and where they choose to live.

If these new technologies are implemented now, they can support our current aging infrastructure, and help to better plan for a future where Australia’s population is even higher.

Jessica Dickers Editor

I’m keen to hear your thoughts and

feedback on Infrastructure. Drop me a line at jessica.dickers@monkeymedia.net.au or feel free to call me on 03 9988 4950 to let me know what you think.

Published by Monkey Media Enterprises

2206-7906

1 October 2017 - 31 March 2018 Issue 8 September 2018 ROAD RAIL AIRPORT PORT URBAN UTILITY THE LOGISTICS OF AUSTRALIA’S BLUE HIGHWAY The technologies DISRUPTING ASSET MANAGEMENT DESIGN PHILOSOPHY OF THE MODERN TUNNEL

650 + ATTENDEES

80 + EXHIBITION BOOTHS

60 + SPEAKERS

REGISTER, PARTNER AND EXHIBIT

LARGEST AIRPORT EVENT IN AUSTRALIA events@airports.asn.au • +61 02 6230 1110 • airportsconference.asn.au BRISBANE 18 AUSTRALIAN

NATIONAL CONFERENCE

AMPLIFY YOUR BRAND AT THE

AIRPORTS ASSOCIATION

13-16 NOV

INDUSTRY INSIGHT

ADDRESSING INFRASTRUCTURE GAPS THROUGH REFORM

SUSTAINABLE MATERIALS IN ROAD CONSTRUCTION

INVESTMENT

STRENGTHENING THE COMMONWEALTH AS AN INFRASTRUCTURE PARTNER

CRANES AND HEAVY LIFTING

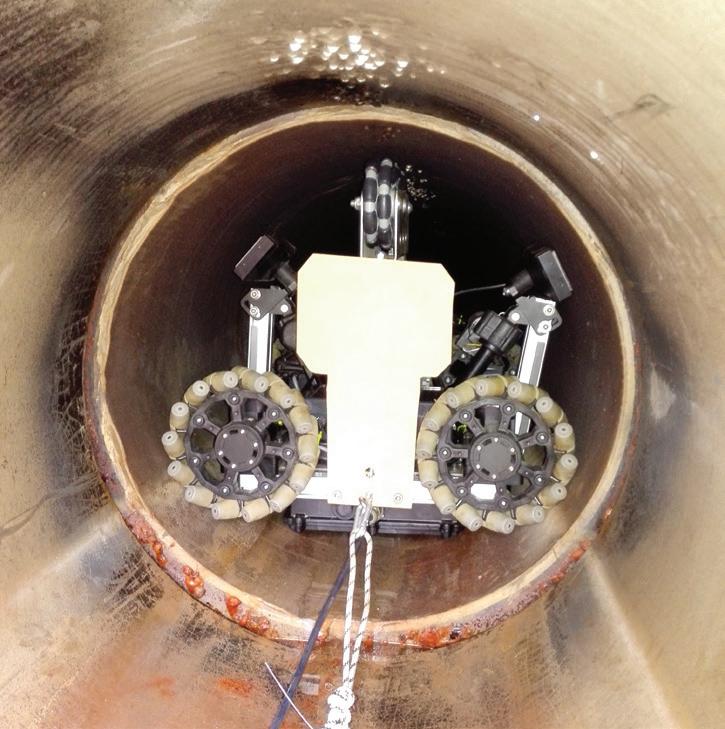

THE FUTURE OF ROBOTICS IN INFRASTRUCTURE

TUNNEL VISION

ROBUST TUNNELLING WATER TREATMENT AND SOLIDS DEWATERING

ASSET MANAGEMENT

JOIN INFRASTRUCTURE EXPERTS AT ASSET MANAGEMENT FOR CRITICAL INFRASTRUCTURE

RUGGED TABLETS SMOOTHING OUT ROAD IMPROVEMENT

CONCRETE AND CULVERTS

WHERE HAVE ALL THE CONCRETE EXPERTS GONE?

INTELLIGENT TRANSPORT SYSTEMS (ITS)

IS AUSTRALIAN INFRASTRUCTURE FUTURE READY? CAN FREIGHT SAVE THE LUCKY

INTELLIGENT INSTALLATIONS - THE

4 September 2018 // ISSUE 8 www.infrastructuremagazine.com.au CONTENTS

PROJECTS MOBILITY AS A SERVICE IN AUSTRALIA: CUSTOMER INSIGHTS AND OPPORTUNITIES

FOR

ROADS

DRIVING AUTOMATED AND ZERO EMISSIONS VEHICLES 60 62 PORTS FREIGHT AND LOGISTICS

PORT OF NEWCASTLE: A GLOBAL GATEWAY FOR REGIONAL AUSTRALIA 56 18 20 24 28 30 32 34 38 46 50 52 42 TUNNELS

IMPACT

VICTORIAN

EVIDENCE

COUNTRY?

SAFETY AND RISK MANAGEMENT

SAFETY IN ACTION

OVERHAULING CONSTRUCTION SAFETY CULTURE

REDUCING DOWNTIME WITH GPS AND 3D MACHINE CONTROL

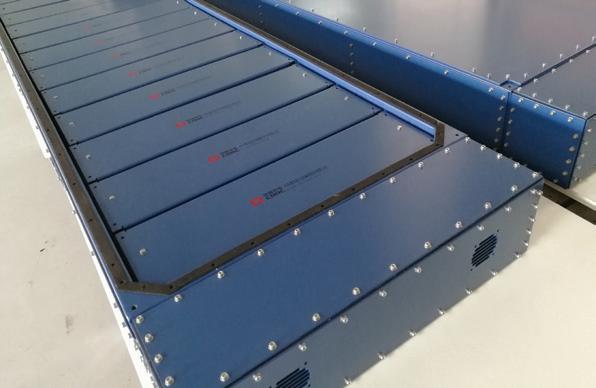

ENERGY INFRASTRUCTURE

SELECTING THE RIGHT FOUNDATION FOR GROUND-MOUNTED PV PANELS

THE ENERGY TECHNOLOGY THAT COULD OVERHAUL TRAM SYSTEMS

LET'S GET CONNECTED - IMPLEMENTATION OF THE CIVIL SKILLS CADETSHIP (CSC) PROGRAM

ACCELERATING SUSTAINABILITY THROUGH INFRASTRUCTURE

08 NEW GUIDELINES FOR INFRASTRUCTURE DECISION-MAKING

SYDNEY BRIDGE DESIGN RELEASED 10 NT GOVERNMENT RELEASES STRATEGIC PLAN FOR INFRASTRUCTURE 11 NORTHERN ROAD CONTRACT AWARDED TO SUPPORT WESTERN SYDNEY AIRPORT

MELBOURNE AIRPORT RAIL LINK SET TO GO AHEAD

CONTRACTS AWARDED FOR INLAND RAIL PROJECT 16 IS TAMWORTH THE HOME OF ‘COUNTRY ROADS’?

5 www.infrastructuremagazine.com.au September 2018 // ISSUE 8 CONTENTS

REGULARS 02

06 CONTRIBUTORS 80

NEWS 76 78

SKILLS AND TRAINING EVENTS 72 74 64 66 70

EDITOR’S WELCOME

ADVERTISERS’ INDEX 80 FEATURES SCHEDULE

08

12

14

Leilani Frew

CEO, Infrastructure and Project Financing Agency

Leilani Frew was appointed as the inaugural CEO of the Commonwealth Government’s Infrastructure and Project Financing Agency (IPFA) in 2017. IPFA is an executive agency that works with the Commonwealth, states and territories, as well as private sector stakeholders and provides independent commercial and financial advice to support the Australian Government’s infrastructure investment decisions. With a career spanning over 25 years, Leilani is a respected and experienced infrastructure finance and advisory professional having held a number of leadership positions in both the private and public sectors. Prior to joining IPFA, Leilani spent nearly five years leading NSW Treasury teams in the provision of commercial and financial advice to the NSW Government and its agencies delivering on the government’s major infrastructure and services commissioning priorities, and serving on a number of government advisory boards and committees. Her contribution to the infrastructure industry was recognised by her peers in 2015 when she received the Women's Achievement in Infrastructure Award from Infrastructure Partnerships Australia.

Mike Gallacher

CEO, Ports Australia

Following an intensive and varied 16 year career as a Police Officer, Mike Gallacher was appointed to the NSW Legislative Council in 1996. He has been the Shadow Minister for a variety of portfolios including Ports, Industrial Relations, Transport and Police. Winning government in 2011, Mike was appointed Minister for Police and Emergency Services, Minister for the Hunter, and later the further role of Minister for Industrial Relations. Mike is widely recognised for his robust approach to policy development and his preparedness to strongly advocate the need for reform. As Minister he led on behalf of government the public debate on issues such as measures to reduce alcohol related violence, rampant gang/gun related crime and introduced initiatives to change driver behaviour. Leaving Parliament in 2017, he has now taken the role as CEO of Ports Australia, the peak industry body for the ports industry.

Ed Taylor

President, Australasian Tunnelling Society (ATS)

Ed is a Chartered Professional Engineer, a Fellow of the Institution of Engineers, Australia, and is currently the President of the Australasian Tunnelling Society and Engineering Manager, Tunnelling at John Holland. His tunnelling experience commenced in Melbourne’s sewer and water construction boom of the early 1970s during the innovative period of hard rock TBM development. This experience lead to a period on the Thomson Dam tunnel works in the early 1980s and then to the Melbourne City Link Road Project, the first in Australia utilising large road headers. This was the first of four major road tunnels where he was employed in engineering management roles for the contractor. Other notable recent projects include Downtown Line Contract 935, Singapore and North West Rail Link, Sydney. He is currently working on the Melbourne Metro project. Ed’s experience on various infrastructure tunnels has enabled him to develop a unique range of technical competencies for which he is well renowned. Over the years he has fine-tuned the balance between the technical requirements of large civil infrastructure projects and the practical needs of construction requirements.

6 Contri

butors

David Millar CEO, Concrete Institute of Australia

David Millar CEO, Concrete Institute of Australia

As a civil engineering graduate from the University of Sydney, David began his career in the concrete aggregates industry before expanding into precast concrete, construction chemicals and concrete materials. With a great appreciation of what industry and professional associations can provide to the concrete industry, David has been, and still is, an active member on a number of concrete related committees as a volunteer. He was also the Executive Director of the Concrete Pipe Association of Australasia from 2005 to 2013 before commencing his current role with the Concrete Institute of Australia in 2014. David’s 25+ years in the construction industry has revolved entirely around concrete, and through this experience he understands the importance this most traditional, but ever evolving, material has on society and the environment.

Anna Chau

Acting Chief Executive, Infrastructure Australia

Anna leads the ongoing development of the national Infrastructure Priority List (IPL) and the assessment of project business case submissions which are considered by the IA Board for the IPL. She is a leading applied economist in infrastructure with 27 years’ professional experience, specialising in transport economics. Anna was previously Chief Economist at AECOM Australia and led AECOM’s national Economics team. Her previous positions include Principal at Booz & Company, Executive Director of EY’s Economics team in Sydney, and Senior Manager in the business development group at a major train operating company in the UK. She has led numerous cost-benefit analyses and business cases, as both a practitioner and a reviewer, in a range of infrastructure sectors, including transport, water and waste, energy, law enforcement, justice, IT and the environment. Her contribution to the transport sector was recognised in 2017 when she was shortlisted as a finalist for the Professional Woman in Logistics and Transport Award by the Chartered Institute of Logistics and Transport Australia (CILTA).

Dr Roberto Perez-Franco

Senior Research Fellow – Supply Chain Strategy, Deakin University

Roberto Perez-Franco is a Senior Research Fellow in Supply Chain Strategy at the Centre for Supply Chain and Logistics (CSCL) at Deakin University where he leads the Supply Chain Strategy Lab, a research initiative dedicated to exploring the long-term, big-picture issues concerning supply chains. Last year, Roberto served as Principal Researcher of the scenario planning project conducted by CSCL for the Department of Infrastructure and Regional Development, to inform Australia’s national inquiry into freight and supply chain priorities, which will inform the National Freight and Supply Chain Strategy to be released early next year.

Before joining Deakin, Roberto spent almost 12 years at the Massachusetts Institute of Technology (MIT), first as a masters and doctoral student, and then as Research Associate at the Centre for Transportation and Logistics (CTL). There he was a member of the core team that conducted the Future Freight Flows project for the United States Government.

7

NEW GUIDELINES FOR INFRASTRUCTURE DECISION-MAKING

Infrastructure Australia has released new guidelines to drive greater accountability and transparency in infrastructure decision-making.

The guidelines aim to reduce instances of major projects receiving funding before appropriate planning and assessment.

Developed by Infrastructure Australia out of a recommendation in the 2016 Australian Infrastructure Plan, the Infrastructure Decision-making Principles are designed to ensure major public infrastructure investments deliver the best outcomes for the community and the best value for taxpayers.

Former Infrastructure Australia Chief Executive, Philip Davies, said the Australian Infrastructure Plan acknowledged that Australia’s governments and the community would benefit from a set of clear principles to

provide a benchmark for high-quality infrastructure decision-making.

“While the Infrastructure Priority List has helped create a credible pipeline of future infrastructure investments, too often we are still seeing instances of projects being committed to before a business case has been prepared, a full set of options have been considered, and rigorous analysis of a potential project’s benefits and costs has been undertaken,” Mr Davies said.

“Ultimately, we want to ensure that community needs are properly understood, all options considered and communities consulted before projects are committed. This should include making better use of existing infrastructure by deploying new technologies or utilising the data we’re already collecting.”

Mr Davies said the Infrastructure Decision-making Principles should act as a guide for Australia’s governments, establishing clear lines of responsibility and accountability for major infrastructure projects, and providing the broader community with a clear set of expectations with which to hold decision-makers to account.

“We want to see Australia’s governments do more to engage with communities, both in communicating long-term infrastructure plans, problem identification and by incorporating community input in a meaningful way into the project development processes.

“Part of this involves being more transparent around project decisionmaking by publicly releasing the analysis and processes that form the basis of funding decisions.

“Many of these principles are already embedded in Infrastructure Australia’s broader approach to providing infrastructure advice, as well as our Assessment Framework, which guides the assessment of nationally significant infrastructure priorities and provides advice to project proponents in preparing their submissions.

“The scale of investment in major projects and the long life of most infrastructure assets warrants rigorous decision-making processes.

“Our hope is that Australia’s governments embrace these Infrastructure Decision-making Principles and give the community added confidence that decisions on public infrastructure projects are robust, transparent and accountable,” Mr Davies said.

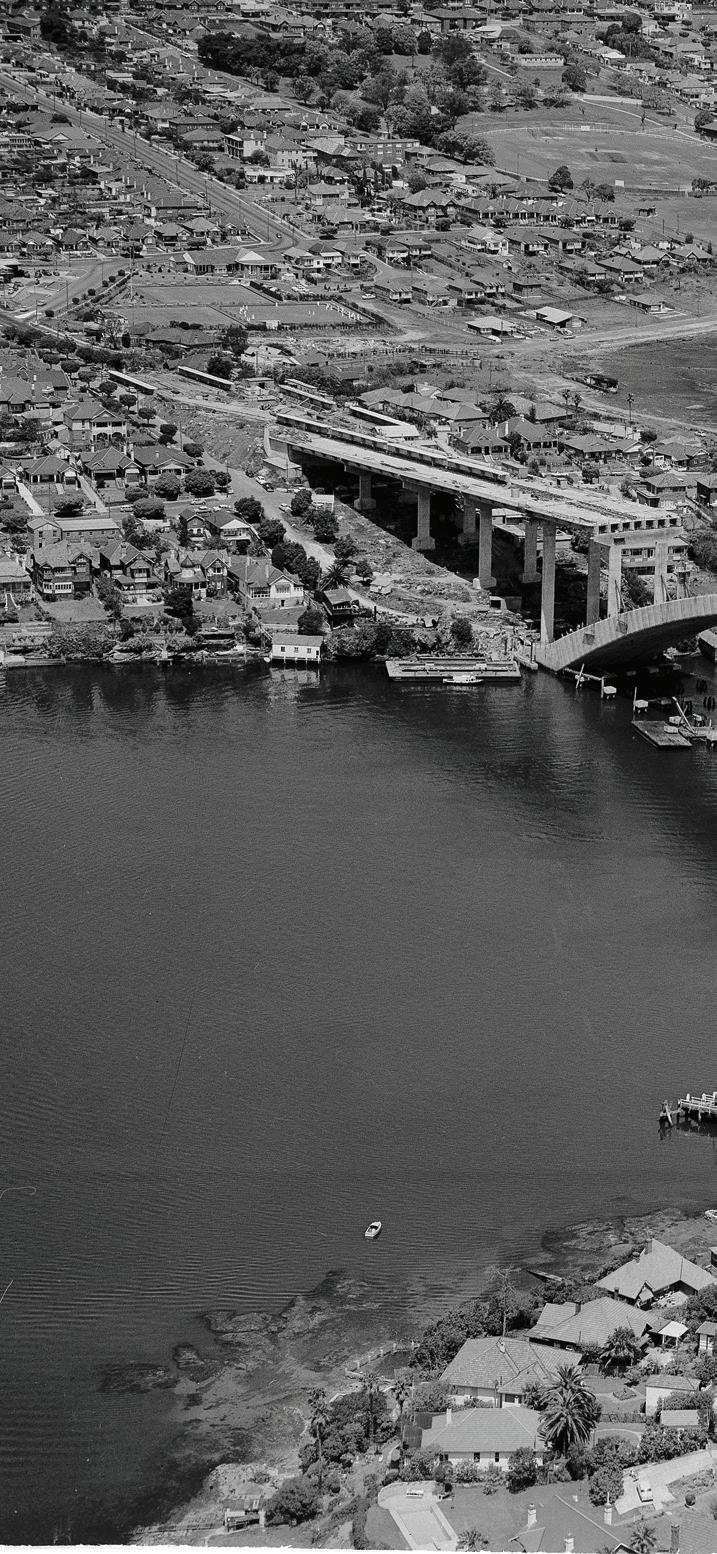

SYDNEY BRIDGE DESIGN RELEASED

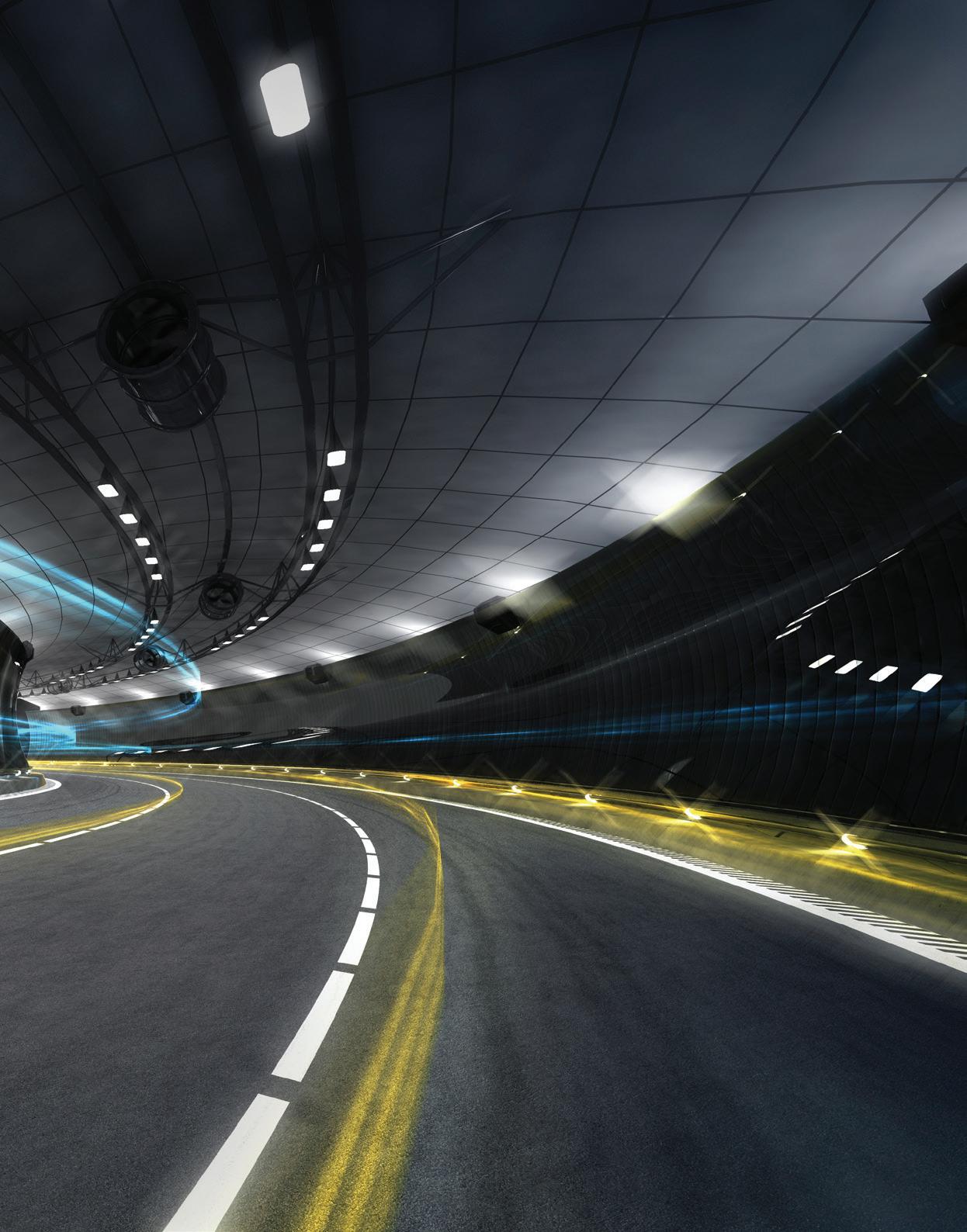

The New South Wales Government has released a detailed design for the Western Harbour Tunnel and Beaches Link, taking pressure off other major bridges in Sydney.

The Western Harbour Tunnel will create a western bypass of the CBD, taking pressure off the Sydney Harbour Bridge, Anzac Bridge and Western Distributor. It will also cut a journey from Olympic Park to North Sydney by 13 minutes, or more than two hours per week.

The Beaches Link will, for the first time, provide a motorway link between the Northern Beaches and the rest of Sydney. It will also reduce the travel time from Brookvale to the CBD by 27 minutes and slash a trip from Dee Why to the airport by 41 minutes.

NSW Premier, Gladys Berejiklian, said since announcing a preferred route last year, the NSW Government has listened to the community and massively improved the locations for the ventilation outlets, reduced the number of properties to be acquired to 37 and sought to minimise construction impacts.

“We know the Western Harbour Tunnel and Beaches Link are important projects that will benefit the wider road network,” Ms Berejiklian said.

“We also know this has been promised over many decades, but only the NSW Liberals and Nationals will deliver it because

the strong economic management of this government means these vital road connections are finally becoming a reality."

Minister for Roads, Maritime and Freight, Melinda Pavey, said the NSW Government had committed $550 million to the projects in the recent Budget. The final cost will be determined when a final design and financing options from the private sector have been finalised.

The detailed design for the Western Harbour Tunnel and Beaches Link will now be subject to extensive community consultation until November, with feedback to be taken on board to refine the design, ahead of the planning assessment phase.

Early works on the projects, expected to start in late 2018, include initial work around the Warringah Freeway and initial work to allow the Western Harbour Tunnel to connect to the Rozelle Interchange.

Subject to planning approvals and finalised financing and procurement, major construction is due to begin in 2020 with the tunnels expected to open to traffic by 2026.

The Western Harbour Tunnel and Beaches Link are part of the NSW Government’s record investment in both public transport and roads, including Sydney Metro Northwest, Sydney Metro City and Southwest, Sydney Metro West, WestConnex and NorthConnex.

September 2018 // ISSUE 8 www.infrastructuremagazine.com.au 8 NEWS

TO EXPECT BESIDES 2 DAYS OF

ARE

YOU

AN ARA MEMBER?

ARA Members receive a 20% discount on conference attendance, sponsorship and exhibition bookings.

YOUNG RAIL PROFESSIONALS – AUSRAIL SHINES A SPOTLIGHT ON TOMORROW’S LEADERS

• Next Generation Scholarship – Entries NOW OPEN! (Available to sponsor)

• Young Rail Professionals Pitching Competition – Finalists to be announced in August (Available to sponsor)

• NEW FOR 2018 – Mentor rate discount available for those 30 years and under (conditions apply)

Visit www.ausrail.com

To sponsor a function, innovative package, exhibit, advertise within the Official Event Guide and much, much more, please contact Deborah Bocock, email: Deborah.Bocock@informa.com.au

THE LARGEST RAIL EVENT IN AUSTRALASIA RETURNS TO THE NATION’S CAPITAL

WHAT

INDUSTRY ENGAGEMENT

Rail – For a Better Future PREMIUM PLATINUM & GALA DINNER SPONSOR PREMIUM GOLD & HERO IMAGE SPONSOR LANYARD SPONSOR EXHIBITION NETWORKING DRINKS SPONSOR APP SPONSOR

70 0+ CONFERENCE AT TENDEES 120+ EXHIBITING ORGANISATION S 4 SOCIAL FUNCTIONS 1 ULTIMATE RAIL NE TWORKING EXPERIENCE SPONSORSHIP

EXHIBITION OPPORTUNITIES

Photo courtesy of CAF

AND

NT GOVERNMENT RELEASES STRATEGIC PLAN FOR INFRASTRUCTURE

The Northern Territory Department of Infrastructure, Planning and Logistics is focused on driving sustainable, economic and social advancement of the Territory through strategic land use and transport planning, infrastructure investment, building regulation and effective logistic supply chains, its 2018-2021 strategic plan has revealed.

The plan will direct the department over the next three years. It aligns with the NT Government’s strategic themes of investing in the bush, trust, putting children at the heart of government, jobs and the economy, and safer and vibrant communities.

The strategic plan is informed by both The Economic Development Framework and the 10 Year Infrastructure Plan. Strategic objectives include:

Long-term planning – Long-term planning that integrates community needs and industry best practice

♦ Provide a more transparent and planned approach to land and planning policy in the NT

♦ Deliver government’s vision for planning across the Territory

♦ Deliver and support Darwin and Alice Springs CBD revitalisation

♦ Deliver the Territory Wide Logistics Master Plan

♦ Implement the Northern Territory Road Safety Action Plan – Towards Zero

♦ Plan for Weddell and Cox Peninsula in partnership with land owners

Infrastructure Delivery – Deliver the Territory’s Infrastructure Program and maintain its Infrastructure Portfolio

♦ Plan and maintain the Territory’s infrastructure portfolio including delivery of government’s extensive infrastructure program ensuring a rolling pipeline of works

♦ Promote government’s infrastructure priorities and achievements as outlined in the 10 Year Infrastructure Plan

♦ Deliver improvements to transport infrastructure including roads, bridges, barge landings and aerodromes

♦ Support the development and implementation of government’s Aboriginal Contracting Framework

♦ Create a safer, more productive contractor environment by ensuring compliance with safety standards and requirements

Quality Services – Deliver innovative, well regulated, safe and sustainable services

♦ Implement contemporary regulatory frameworks that support innovation and efficiency, reduce red tape and deliver safe outcomes. This includes a review of building regulatory framework, progression towards swimming pool safety reform and progression towards planning reform

♦ Improved service delivery and increased online service options at Motor Vehicle Registries

♦ Develop and deliver a regulatory model to facilitate ridesharing in the Northern Territory

♦ Develop policy options which support autonomous and electric vehicles in the NT

Contemporary Organisation – Create an organisation with the values, capacity and capability to deliver effective services

♦ Create workplaces that foster innovation and promote excellence, underpinned by a culture of collaboration

♦ Ensure our worksites and working arrangements prioritise the health and safety of staff, where risks are identified and effectively managed

♦ Develop programs to recruit and retain quality staff, develop leadership and workforce capability, including a focus on Aboriginal employment

♦ Explore and develop new ways of doing business that create efficiencies in our operations and enable agile responses to changes in our environment

September 2018 // Issue 8 www.infrastructuremagazine.com.au 10 NEWS

NORTHERN ROAD CONTRACT AWARDED TO SUPPORT WESTERN SYDNEY AIRPORT

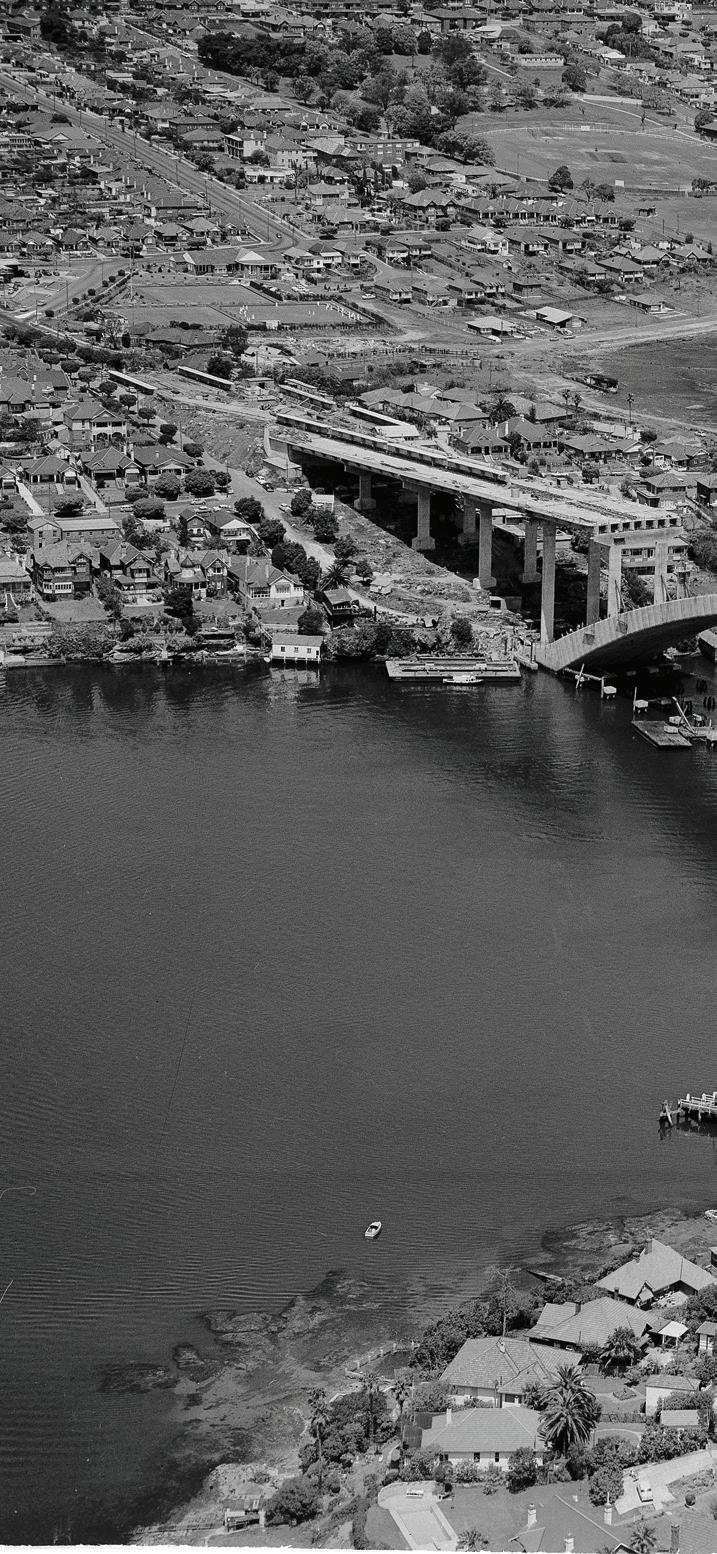

Major progress is being made on the construction of The Northern Road in Western Sydney, with the bridge at the M4 Motorway interchange now being built.

Federal Minister for Urban Infrastructure and Cities, Paul Fletcher, said the upgrade was part of the $3.6 billion Western Sydney Infrastructure Plan, delivering new and upgraded roads in preparation for the new Western Sydney Airport.

“The Turnbull Government is committed to ensuring that Western Sydney will capitalise on the huge economic benefits that will flow from our $5.3 billion commitment to build Western Sydney Airport. This is possible because of a stronger economy,” Mr Fletcher said.

“Together with the Berejiklian Government, we’ve signed the Western Sydney City Deal with eight Western Sydney Councils, setting out a clear plan to attract business and generate jobs for the region, and along with our commitment to have the new airport connected to rail when it opens, we are delivering the transport and jobs that Western Sydney needs to thrive.”

“Infrastructure is about more than bridges, roads and airports, it is an opportunity to build stronger communities by connecting people to jobs closer to home,” Mr Ayres said.

“Crews are installing 40 of these massive 32m long super-T girders using a 600-tonne crane, with the new bridge to be complete by early next year.”

Senator for Western Sydney, Marise Payne, said there was major progress being made on The Northern Road upgrade Stage 3 between Glenmore Parkway at Glenmore Park and Jamison Road at South Penrith, with start of work on the new bridge at the M4 Motorway interchange a significant milestone for the project.

NSW Minister for Western Sydney and Member for Penrith, Stuart Ayres, said the Northern Road upgrade is part of a huge investment in Western Sydney roads, jointly funded by the Australian and NSW Governments.

“This new upgrade is a real win for Western Sydney motorists, particularly for residents in Glenmore Park and Penrith who use the M4. Delivery of this project will mean more time with your family and less time spent on the road,”

Ms Payne said.

While work is carried out, the M4 Motorway will be closed between 10pm and 8am between the M4 Motorway entry and exit ramps to The Northern Road to allow work to be carried out safely.

The Australian Government has committed $1.2 billion to the $1.6 billion Northern Road Upgrade with the New South Wales Government funding the remainder.

www.infrastructuremagazine.com.au September 2018 // Issue 8 11 NEWS

MELBOURNE AIRPORT RAIL LINK SET TO GO AHEAD

Major work will commence on the Melbourne Airport Rail Link under a re-elected Andrews Labor Government, with the State Government providing up to $5 billion towards the construction of the much anticipated project, matching the commitment of the Federal Government.

A route options assessment undertaken by Transport for Victoria has shown that of the four routes considered, the Sunshine alignment – previously known as the Albion East alignment – is the Victorian Government’s preferred route for the project.

The Sunshine Route will see trains travel to the airport from the CBD via a new Sunshine Super Hub, which will connect regional and metro train lines –including the Metro Tunnel – to the new airport link.

This new transport hub will also pave the way for fast regional rail services

from Geelong and Ballarat, connected to Melbourne Airport, via just one change.

From Sunshine, trains will head north utilising both the Albion East rail reserve and sections of tunnel to protect homes and businesses, before connecting in to Melbourne Airport.

The rigorous new analysis produced as part of initial work on the Airport Rail Link Business Case shows that the Sunshine Route rated 4.3 out of five overall in the comparative analysis of routes, with a total cost in the range of $8-13 billion.

Funding under a re-elected Andrews Labor Government will match funding from the Commonwealth, while private sector contributions will also play a part in the delivery of the project.

The Federal Government was briefed on the outcome of the route options assessment in early July 2018 and work is underway on the full business case which will be completed by Rail Projects Victoria in 2019.

Mobile Laser Scanning

• Terrestrial Laser Scanning

• 3D Modelling and BIM

• Drone mapping

• Z boat hydrographic surveys

• Virtual and Augmented Reality Solutions

• TIMMS (Trimble Indoor Mobile Mapping System) preliminary development estimates

• servicing advice on master planning

• roads, earthworks, drainage, sewer and water main design

• water quality modelling

• site and environmental management plans www.taylorsds.com.au

• construction surveillance, field audits

Melbourne | Brisbane | Perth | Christchurch | Jakarta NEWS September 2018 // ISSUE 8 www.infrastructuremagazine.com.au 12

GEARING UP FOR THE STATE’S LARGEST MAJOR PROJECTS CONFERENCE

The 10th Annual NSW Major Projects Conference will be returning on the 21st & 22nd November 2018 at the International Convention Centre in Sydney.

Attracting upwards of 250 delegates annually, this two-day event continues to be the state’s largest major projects and infrastructure conference. Over the course of the event, attendees will have the opportunity to cultivate industry connections through key networking events.

With over 20 expert speakers and government policy makers discussing major infrastructure projects, attending delegates will be provided with a glimpse at key updates and best practice solutions for future projects.

Chief Executive Officer of Infrastructure NSW, Jim Betts, will present on the future of NSW’s infrastructure and its impression on the states expected $1.3 trillion economy.

In a complementary presentation, Kiersten Fishburn, Chief Executive Officer of Liverpool City Council will explore the influence of the impending Western Sydney Airport on the Liverpool area.

Touching on some of the state’s largest infrastructure projects to date, the 10th Annual NSW Major Projects Conference is guaranteed to be a must-attend event.

www.nswconference.com.au

SYDNEY INTERNATIONAL CONVENTION CENTRE

NOVEMBER 21 - 22

CONTRACTS AWARDED FOR INLAND RAIL PROJECT

The Australian Rail Track Corporation (ARTC) has appointed its first preferred construction contractor and awarded contracts for the Inland Rail project.

INLink is the preferred construction contractor for the Parkes to Narromine section of Inland Rail. Calvani Crushing and Ausrock Quarries have also been awarded contracts for ballast and capping work on the project.

The appointment allows INLink, a joint venture with BMD Constructions and Fulton Hogan, to begin preparing for the start of construction for Inland Rail later this year.

Inland Rail CEO, Richard Wankmuller, said INLink would be scoping out suppliers in the market with many opportunities for regional companies and local businesses.

“With early works on Inland Rail now well under way, residents and local businesses will increasingly see the flow on benefits, including jobs and new investment opportunities.

“INLink will be putting together their environmental management plans and applying for their Environment Protection Licence to lay the foundations for major construction,” Mr Wankmuller said.

The economic benefits of Inland Rail continue to flow with up to 16 new jobs created in the Parkes region, as two local companies, Calvani Crushing and Ausrock Quarries, work to supply about $7 million in ballast and capping for the project’s first stage in NSW.

Calvani Crushing has been awarded a $4.8 million contract to supply more than 150,000 tonnes of ballast and 75,000 tonnes of capping; while Ausrock Quarries has been awarded a $2.1 million contract to supply more than 45,000 tonnes

of ballast and 45,000 tonnes of capping. This product will be delivered over the next 12 – 18 months.

Mr Wankmuller said the first track for Inland Rail will be laid later this year between Parkes and Narromine, and there is now a steady stream of supply contracts bringing jobs and opportunities to various parts of Australia.

“Inland Rail is securing jobs in regional Australia and our cities. We now have ballast and capping supplied from Parkes, concrete sleepers from Mittagong, steel track from Whyalla; and there are many other significant contracts to be awarded,” Mr Wankmuller said.

“This is just the beginning job-wise. Inland Rail is gathering momentum each day and is delivering on its great potential. It’s expected to deliver 16,000 new jobs at peak construction, and an average of 700 additional jobs a year over the entire program.”

About 3.6 million tonnes of ballast and 3.4 million tonnes of capping will be required for the 1,700km length of Inland Rail, which will provide further opportunities for quarries in regional areas along the rail alignment.

September 2018 // Issue 8 www.infrastructuremagazine.com.au 14 Unified Critical Communications for the Utilities sector www.simocowirelesssolutions.com inquiry.aus@simocowirelesssolutions.com Tel: +61 1300 363 697 NEWS

new digital magazine from Infrastructure

Your look at the biggest issues in the rail sector, from in-depth expert features, to news, events, and a round up of exactly what the industry is talking about.

Subscribe today at infrastructuremagazine.com.au/railmonthly

RAIL MONTHLY A

Introducing

IS TAMWORTH THE HOME OF ‘COUNTRY ROADS’?

When the Centre for Pavement Engineering Education (CPEE) recently staged a training course in Tamworth, much of the information presented was “music to the ears” of the delegates wishing to learn how to better manage their road network.

With Australia having over 800,000km of roads, it was a surprise for the delegates to learn that two thirds of them are unsealed, and that it takes quite a different engineering mindset to maintain this network compared to a sealed road network.

For a sealed pavement, it is the impact of commercial vehicles that eats into the pavement life, and the impact of cars and light vehicles can largely be ignored.

Unsealed roads fail through surface wear, most significantly when the ‘sheeting layer’ slowly disappears in a cloud of dust — and a chorus of complaints. In these situations, the damaging effect of cars is just as important as trucks.

Because of this, unsealed roads can be a large consumer of natural materials. How sustainable is this and what engineering controls can be used to manage this?

These and many other unsealed road quirks and issues were explained and discussed at a two-day training course held by CPEE in Tamworth recently, which was attended by local government staff from Tamworth and several adjoining councils.

Many of the delegates were surprised at the number of tools and options available to help manage their networks. Some of them said they wished that their councillors could have attended too!

Tamworth is well known as Australia’s home of country music, but what if it were to become the home of country roads as well?

For more information, please visit www.pavementeducation.edu.au

E N H A N C E Y O U R T E C H N I C A L C A P A B I L I T I E S

is Australia’s premier provider of higher education and training in roads, pavements and infrastructure asset management. Offering online postgraduate programs alongside specialist short courses and workshops MASTER OF PAVEMENT TECHNOLOGY Short Courses Workshops Masters Graduate Certificates BACHELOR OF ENGINEERING TECHNOLOGY (PROFESSIONAL HONOURS IN INFRASTRUCTURE ASSET MANAGEMENT) w w w . p a v e m e n t e d u c a t i o n . e d u . a u [ 0 3 ] 9 8 9 0 5 1 5 5 Roads, Pavements and Infrastructure Asset Management NEWS // PARTNER SOLUTIONS September 2018 // ISSUE 8 www.infrastructuremagazine.com.au 16

CPEE

Australian Tunnelling Conference

Best practice in tunnelling design, construction and maintenance 15 – 16 October 2018

TECHNOLOGY SHOWCASE SPONSORS: EXHIBITORS:

LANYARD SPONSOR: SPECIAL RATEAUSTRALASIAN TUNNELLING SOCIETY MEMBERS SAVE UP TO $600!

SUPPORTED BY:

Conference

Function Centre PRESENTING THE 15TH ANNUAL REGISTER NOW www.informa.com.au/tunnellingconf

| SMC

&

ADDRESSING INFRASTRUCTURE GAPS THROUGH REFORM

by Anna Chau, Acting Chief Executive, Infrastructure Australia

by Anna Chau, Acting Chief Executive, Infrastructure Australia

When Infrastructure Australia published the Australian Infrastructure Plan in February 2016, we set out a national reform agenda to address today’s infrastructure gaps and meet the challenges of the future.

made 78 comprehensive

way we plan, deliver and use our infrastructure.

These recommendations were comprehensive and long term, and laid out for Australia’s governments the reforms and investments needed to drive productivity, improve our standard of living and deliver world-class services in our cities and regions.

We knew, however, that the national reform agenda we put forward would only be as good as the commitments and leadership that followed.

To keep up the momentum on reform and encourage Australia’s government to stay the course over the long term, we have released a new report, Prioritising Reform, which reviews the progress made against the key recommendations in the 2016 Plan.

WHAT PROGRESS HAS BEEN MADE?

The Australian Infrastructure Plan

recommended a material increase in both public and private infrastructure funding to meet the needs of Australia’s growing population and drive productivity growth.

It’s pleasing then to report an upward trend in public and private infrastructure investment in transport, energy, water and communications, which has been discernible since early 2016.

This has been driven primarily by increased investment in transport infrastructure, which is the biggest category of spending in each state and territory – and represents about half of all private and public spending across the four sectors.

Another positive development highlighted in Prioritising Reform is the improved quality of long-term integrated infrastructure planning occurring across the country.

Our four largest cities, Sydney, Melbourne, Brisbane and Perth, have improved their metropolitan-level planning and coordination, while forward-thinking action has been taken to protect strategically important infrastructure corridors in New South Wales and Queensland.

We have also been pleased to see the Australian Government take up Infrastructure Australia’s recommendation to establish a National Freight and Supply Chain Strategy to define nationally significant freight corridors and precincts.

This action will be critical to meeting the growing national land freight task, which is set to grow by 86 per cent between 2011 and 2031.

WHAT REMAINS TO BE DONE?

While our recommendations have guided progress in these and other areas, there has been little or no progress on other critical opportunities for reform.

The Australian Infrastructure Plan recommended that more work be done to develop stronger market characteristics in the urban water sector to meet significant challenges over coming decades.

However, it is clear that urban water reform has stalled and progress towards full cost recovery and independent price regulation has slowed and in some instances, reversed.

The continued absence of a national

September 2018 // Issue 8 www.infrastructuremagazine.com.au

18 INDUSTRY INSIGHT

Anna Chau, Acting Chief Executive, Infrastructure Australia

population policy has fostered uncertainty around how to manage Australia’s growing population.

It is also needed to inform better infrastructure planning by correctly projecting the costs, benefits and optimal timing of major projects.

Progress on how we fund and deliver our roads has also stalled. The Plan recommended that the Australian Government initiate an inquiry into the potential benefits and impacts on road market reform, with a view to transitioning to a fairer user-pays approach.

The Australian Government signalled its support for this approach in 2016, however no inquiry has been forthcoming.

IMPROVING TRANSPARENCY AND ACCOUNTABILITY IN PROJECT SELECTION

A significant focus of the Australian Infrastructure Plan was the need for greater transparency and accountability in infrastructure decision-making and project selection.

The Infrastructure Priority List, a prioritised list of nationally significant investments assessed by the independent Infrastructure Australia Board, has helped guide investment towards projects with demonstrated economic benefits.

The update to the Infrastructure Priority List in March this year included $55 billion worth of projects, with $25 billion worth of projects moving off the list and into the delivery phase.

Australia’s governments are increasingly favouring a more methodical process for selecting major infrastructure projects, while the standard of business cases for major infrastructure projects has improved markedly.

Infrastructure Australia has been proud to work closely with the states

and territories to raise the quality of business cases, including by hosting workshops around the country to improve proposal development.

Greater collaboration between federal and state jurisdictions has further supported the development of quality business cases, as has the creation of dedicated infrastructure agencies in each state and territory.

However, early stage project funding announcements remain a concern. Too often we are still seeing instances of projects being committed to before a business case has been prepared, a full set of options have been considered, and rigorous analysis of a potential project’s benefits and costs has been undertaken.

These announcements risk foreclosing on other, possibly better, options, which can be costly for taxpayers and undercut public confidence in government decision-making.

A CLEAR SET OF PRINCIPLES TO GUIDE DECISION-MAKING

Building on our recommendation in the 2016 Plan, Infrastructure Australia has recently released the Infrastructure Decision-making Principles, a set of clear guidelines designed to ensure major public infrastructure investments deliver the best outcomes for the community and the best value for taxpayers.

These 11 principles set a new benchmark for high-quality infrastructure decision-making and should act as a guide for Australia’s governments, while also providing the community with a clear set of expectations with which to hold decision makers to account.

Our hope is that Australia’s governments embrace these Infrastructure Decision-making Principles as they will give the community added confidence that decisions on public infrastructure projects are robust, transparent and accountable.

19 INDUSTRY INSIGHT

SUSTAINABLE MATERIALS

By Jessica Cairns, Senior Sustainability Advisor, Transurban

Increasing the uptake of sustainable materials across the roads sector is one of the infrastructure sector’s biggest challenges. To tackle this issue, Transurban Queensland and the Infrastructure Sustainability Council of Australia (ISCA) recently joined forces to host an industry forum and workshop solutions.

This forum brought together more than 60 representatives from the Department of Transport and Main Roads, Brisbane City Council and Brisbane Airport, as well as key road contractors and materials providers, to look critically at some of the key challenges associated with using sustainable materials in motorway construction.

Significant quantities of resources are consumed to build, operate and deconstruct infrastructure across the globe. In fact, across Australia, there is an estimated $55 billion worth of high priority infrastructure planned,

including approximately $8 billion of funding committed to building roads in Queensland over the next five years1

This presents a considerable opportunity to reduce the environmental and social impact of these upcoming projects, and strong participation in this forum is a positive indicator that there is a real willingness and ability to make some meaningful changes to the way materials are specified and used.

THE IMPACT OF MATERIALS

The impacts of material use go well beyond construction, with potential effects on the environment and

communities occurring across the full lifecycle of a project. For example, a typical two-lane bitumen road with an aggregate base can require up to 25,000 tonnes of material per kilometre2

The key stages of a material's lifecycle are:

♦ Extraction and treatment of raw materials

♦ Product manufacturing

♦ Transport and distribution

♦ Maintenance and replacement requirements

♦ End-of-life requirements to recycle or send materials to landfill

To reduce the overall impacts,

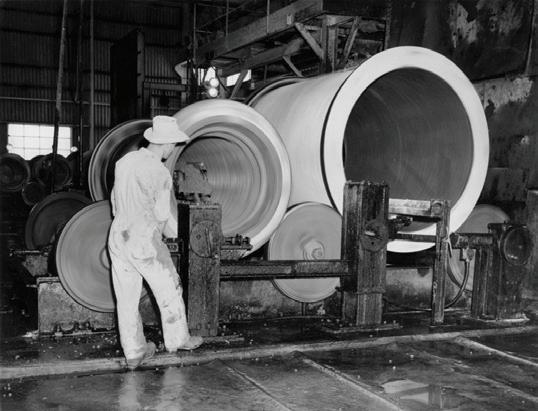

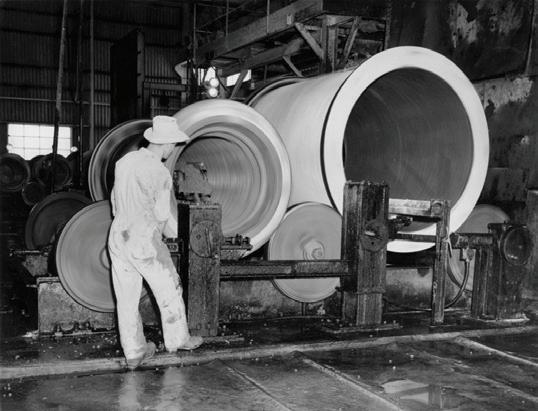

EME2 production on the Logan Enhancement Project, early 2018.

Enrobé à Module Élevé (EME2) was developed in the 1980s and is designed to reduce the thickness of pavement without compromising on performance requirements. The Logan Enhancement Project will be among the first projects in Australia to use this product and is planning to use approximately 220,000 tonnes over approximately 8-10kms of heavily trafficked road. Current estimates suggest the overall thickness of asphalt will be reduced by 17.5 per cent, saving approximately 62,000 tonnes of asphalt.

September 2018 // Issue 8 www.infrastructuremagazine.com.au

Major Projects Pipeline’ Infrastructure Association of QLD report, 2018 2 Reducing the environmental impact of road construction, Sustainable Built Environment National Research Centre 2012 20 INDUSTRY INSIGHT

1

IN ROAD CONSTRUCTION

stakeholders involved across the full lifecycle need to be engaged and willing to consider alternative design solutions, new and improved products, and different ways of working together to deliver better outcomes.

INDUSTRY COLLABORATION

On 29 May 2018, ISCA and Transurban Queensland facilitated a workshop with representatives from across industry and a number of key speakers.

Transurban Queensland Group Executive, Sue Johnson, opened the forum and said Transurban was passionate about bringing industry members together to work through the challenges of sustainable infrastructure.

“We are committed to sustainability across the full lifecycle of our road assets,” Ms Johnson said.

“We’re working to use more sustainable materials in our road projects and are excited to work with industry to explore opportunities to take this much further than what is currently best practice.”

Ms Johnson said the forum was a small but important step forward and Transurban Queensland was committed to continuing to build momentum in this area.

The format of the event was designed to encourage discussion, collaboration and inspire participants to consider solutions and actions for each challenge. Short presentations, delivered by key speakers across a range of different topics, were followed by workshop sessions and action planning across six topics:

♦ Innovation and the relationship with specifications – facilitated by Mike Pickering, Department of Transport and Main Roads

♦ Using sustainable materials in

practice – facilitated by Peter Murphy, Alex Fraser

♦ Enabling the supply chain –facilitated by Robin Mellon, The Supply Chain Sustainability School

♦ Balancing risk and innovation –facilitated by Darren Leeson, Jacobs

♦ Collaboration – facilitated by Daniel Baker and Angela Hili, Transurban Queensland

♦ Leadership – facilitated by Kieren Heikkinen, ISCA

KEY OUTCOMES

This event included professionals from the public and private sector, and with various technical and non-technical backgrounds. The willingness for 60 professionals to come together and discuss options for overcoming challenges related to sustainable materials is an outcome in itself.

A number of key messages emerged from the workshop:

Message 1: Creative and targeted contract requirements reduce barriers and deliver outcomes

The most consistent and common message was the need to use contract structures, requirements and tender processes, to effectively incentivise sustainability, reduce risk around innovation, encourage open communication and knowledge sharing, and set minimum standards for sustainability performance.

21 INDUSTRY INSIGHT

www.infrastructuremagazine.com.au

Having clear and measurable requirements for sustainability in a contract will allow the contractor to understand and have adequate time to identify solutions and prepare their response. It also means that the client or project lead agency will have a set of initiatives that can be used to measure performance. The Infrastructure Sustainability (IS) rating scheme can be used to set minimum requirements and can also be used as a framework to incentivise performance. Further assistance in helping the supply chain to understand requirements, and providing adequate support, is necessary to increase the use of sustainability requirements in contracts. Starting engagement early will also help to break down barriers between project parties and create a culture of knowledge sharing and positive decision-making.

Message 2: Performance-based specifications

One of the biggest barriers to implementing new or alternative products is the process required to either adjust road agency specifications, or demonstrate compliance with an already approved specification. Throughout a number of

discussions, a need for performance-based specifications was expressed.

Specifications are required to make sure structures are safe, durable and perform as needed. At times, detailed and prescriptive specifications limit the ability for industry to innovate and try new things. Performance-based specifications use performance indicators and standard acceptance criteria to determine the suitability of a product. They do not specify the exact details of any particular product that should be used. For example, they would not prescribe the concrete mix proportions.

This format gives industry greater scope to innovate and, based on the feedback from the forum, is an important aspect for improving the application of sustainable materials and products.

Message 3: Industry collaboration for new and innovative products

Before new or innovative products are implemented on a project, there is usually a significant amount of time where

September 2018 // Issue 8 www.infrastructuremagazine.com.au 22 INDUSTRY INSIGHT

solutions are conceptualised, socialised, tested and trialled. This process requires collaboration and input from stakeholders right across the value chain.

A common question is around ownership and who should drive innovation in this area. If a client doesn’t ask for sustainable options, a contractor may not feel it is their responsibility to invest in and deliver these options. At the same time a client may feel they can’t ask for a specific requirement because they don’t know what is available or possible, along with the associated cost, risk and performance differences.

The solution is for clients, contractors and suppliers to collaborate throughout the innovation process and to actively

THE INDUSTRY BODIES

The Infrastructure Sustainability Council for Australia is the peak industry body for infrastructure sustainability. The Infrastructure Sustainability (IS) rating scheme is facilitated by ISCA and applies to the design, construction and operation of infrastructure. Transurban is a member of ISCA and currently mandates the use of the Infrastructure Sustainability rating scheme on all major projects.

The Supply Chain Sustainability School is a national not-for-profit initiative. The school represents a collaborative approach to developing environmental, social and economic sustainability competencies through the supply chain. It is a free resource, available to any team, client or supplier working in the construction industry, and is part of a continued commitment to lead the industry into a more prosperous, sustainable future.

communicate the costs and benefits of new and alternative products once they have been tested or trialled.

There are a number of challenges related to collaboration, including competitive advantage and the need to protect intellectual property, the fast-paced nature of construction and infrastructure planning, and finally, sometimes there is a lack of desire to do things differently. Industry peak bodies and working groups can play a major role in overcoming many of these challenges. Road agencies can also assist in driving more innovation by leading the charge and setting a policy objective to reduce the impact of materials in construction.

Message 4: Accept failure for innovation

In a sector where failure and mistakes can have catastrophic impacts on life, communities and cities, it is not surprising that overall stakeholders involved in the construction of transport infrastructure are generally risk averse, fearing failure. However, failure can be an essential part of the innovation process and it is equally important for industry to communicate failure, along with success. Participants suggested that a consistent methodology could be used for measuring and monitoring innovation to overcome this particular barrier. More generally, there needs to be a shift in thinking that encourages people to take risks and celebrate the lessons, regardless of outcomes.

Message 5: Education to increase consistency in language and approach

Almost all participants raised the need for greater education and consistency across industry. This also relates to knowledge sharing and collaboration. Unfortunately, sustainability still comes with many negative connotations across the construction sector. It is often associated with being ‘green’ and 'doing without', or sometimes costing a project more money, creating delays and not supporting overall project objectives. The participants agreed that a consistent process for communicating and quantifying the benefits from sustainability initiatives, including new materials and products, is urgently needed to help stakeholders throughout our supply chains understand the drivers behind improving the overall sustainability of the infrastructure sector.

The Supply Chain Sustainability School provides a range of free resources for educating the supply chain around key sustainability requirements and opportunities.

A full report, including a detailed set of findings and next steps will be available on the ISCA website from October. For any further information, contact ISCA or Jessica Cairns directly.

www.infrastructuremagazine.com.au September 2018 // Issue 8

23 INDUSTRY INSIGHT

STRENGTHENING COMMONWEALTH INFRASTRUCTURE

Tmore important that we are strategic around both what we invest in and how we invest. In particular, this more strategic focus on ‘what’ and ‘how’ requires the Australian infrastructure industry to continue its journey of evolution.

STRENGTHENING THE INTEGRATION OF THE

‘WHAT’

The need for greater strategic planning has been a well accepted development over the last few years; the creation of Infrastructure Australia and the infrastructure bodies around the nation focused on the what, why and when, has been a critical development in our sector.

The recognition that infrastructure is no longer thought of as the end but as the means to enable services and deliver outcomes for citizens has underpinned business cases and procurements for projects currently being delivered.

by Leilani Frew, CEO, Infrastructure and Project Financing Agency (IPFA)

The provision of infrastructure in Australia faces challenges from vast distances, a population that is concentrated in sprawling cities, finite financial resources within our economy, competition between freight and commuter uses on many corridors, and citizens who expect quality outcomes that meet their needs and deliver on promised benefits.

The focus on placemaking and land use in recent times, particularly through City Deals, has created an environment where infrastructure planners embrace the challenge of developing future connectivity solutions for citizens that allow us to work, live and play in an integrated manner.

STRENGTHENING

THE INTEGRATION OF THE ‘HOW’

According to analysis of state, federal and territory budgets by Infrastructure Partnerships Australia, from 2018-2021 we will see around $170 billion in public infrastructure investment across all sectors.

This quantum of investment means now is the time to have a greater acknowledgement that it takes a village of equally capable partners with key roles to play in order to raise an infrastructure project.

Whether its private sector businesses of contractors, investors, financiers or

operators, not-for-profit organisations, local councils, state governments or the Commonwealth Government, we all have a role to play in delivering infrastructure-enabled services for citizens.

As with our placemaking and connectivity solutions, we need to deliver these services in a more integrated way. As a sector, we must also ensure that we each have the right capability to deliver both as individual organisations and collectively as the village.

THE INTEGRATION OF THE COMMONWEALTH AS AN INFRASTRUCTURE PARTNER

This focus on strengthened integration in delivering infrastructureenabled services creates a real opportunity to sharpen how the Commonwealth invests and partners with the states and the private sector to deliver improved services and outcomes.

September 2018 // Issue 8 www.infrastructuremagazine.com.au 24 INVESTMENT

Leilani Frew, CEO, Infrastructure and Project Financing Agency (IPFA)

STRENGTHENING THE COMMONWEALTH AS AN INFRASTRUCTURE PARTNER

This is my challenge as CEO of the Infrastructure and Project Financing Agency (IPFA), to strengthen the Commonwealth’s capacity as an investor and to provide the right capability to help the Commonwealth play its role in the collective infrastructure partnership so as to deliver for citizens and taxpayers.

IPFAs focus on applying the Commonwealth’s strategic investor mindset to its $75 billion commitment to transport infrastructure investment over the next decade acknowledges the responsibility of ensuring that taxpayer dollars are invested in a way that delivers them maximum returns. These returns could be in the form of outcomes and, if possible, the recycling of some or all of their investment back into other national infrastructure projects.

IPFAs team has a number of members who have private sector investment and/ or financing experience so we appreciate the value that private sector money, innovation and execution capability brings into infrastructure projects.

We particularly value private sector views on how government can best structure a deal to maximise private sector financing and contributions.

RETURN ON INVESTMENT

At IPFA, we are also very conscious that for some projects there is a need for taxpayer dollars to be invested. However, we want to be as clinical as we can in understanding this need and we want to ensure some return on this investment where we can.

For example, if taxpayer dollars are required to bridge the creation of markets, user pay revenue streams, or for regulatory certainty, then it is reasonable for the taxpayer to have the

opportunity to get some or all of its investment back.

Yes, this comes with the risk that the investment may not be returned but a grant comes with a 100 per cent guarantee that the taxpayer will not have the opportunity to get anything back. Furthermore, a purely grant-based approach will not create the opportunity to recycle investments into other national infrastructure needs.

Grant funding will always be a significant feature of the Commonwealth’s investor approach. IPFAs mindset of maximising private sector financing opportunities and maximising the return package for taxpayers (outcomes and if possible,

investment) will help increase the transparency of decisions on grants, with a clear focus on outcomes.

For example, IPFAs work with the Department of Environment and Energy to provide a financial contribution to the Solar Reserve concentrating solar thermal project in South Australia is focused on ensuring the structure of the Commonwealth funding can sit alongside private sector investors and financiers and benefit from the commercialisation of the project that the taxpayer’s contribution is enabling.

ADVICE TO COMMONWEALTH

In bringing our commercial experience to the table our focus is on providing

www.infrastructuremagazine.com.au September 2018 // Issue 8

INVESTMENT

25

Leilani presenting at the 12th Annual Infrastructure Oration and 2018 National Infrastructure Awards Dinner (27 May 2018).

September 2018 // Issue 8 www.infrastructuremagazine.com.au 26 INVESTMENT

Leilani, Deputy Prime Minister and Minister for Infrastructure and Transport, the Hon Michal McCormack MP, and Department of Infrastructure Secretary, Dr Steven Kennedy, at the IPFA one year anniversary event.

in-house advice to the Commonwealth on the ‘how’ of infrastructure investment and providing the expert capability to implement the infrastructure governance, commercial delivery and financial arrangements with our state, territory, local council and/or private sector partners.

Our team has a mix of private sector, public sector and public-private sector members. This allows us to speak the different languages of our partners, which we find helps facilitate stronger partnerships, greater appreciation by the Commonwealth of our partners perspectives, and better implementation.

The government’s City Deals are the best example of where an integrated ‘what’, an integrated ‘how’, and Commonwealth integration as a partner, is coming together.

Leveraging off the Commonwealth’s investment in the Western Sydney Airport, the Western City Plan developed by the Greater Sydney Commission and the joint funding commitments to the new North-South Rail line from St Mary’s to Bringelly, the Western Sydney City Deal is a partnership between the three levels of government. It will deliver a once-in-a-generation transformation of Sydney’s outer west to catalyse investment, development and employment, including via the development of the Western Sydney Aerotropolis.

IPFA has used its commercial advisory and financial sector capability to assist the Commonwealth in negotiating with the NSW Government to establish the Authority, which will have responsibility for planning and delivering the land use outcomes for the new city. In addition, we are working with the NSW Government and local councils to maximise private sector partnership opportunities to contribute to the development of the Aerotropolis.

Just as importantly, we are working through arrangements with the NSW Government to tap into the value uplift on surrounding land created by the new rail link (and Western Sydney Airport itself) within the Aerotropolis.

These additional streams of revenue will be shared by the Australian Government and NSW to offset the cost of rail and will help stretch taxpayer dollars to fund more projects. They will also ensure that taxpayers nationwide who ultimately fund the delivery of the North-South Rail asset can share in the value it creates.

COLLABORATION AND PARTNERSHIP KEY

The Commonwealth Government needs the right capability and expertise, including commercial and financial capability, to partner with states, territories, local councils and the private sector if we are going to collectively deliver, finance and fund the infrastructure outcomes for citizens.

From my perspective as IPFA CEO, collaboration and partnership through commercial and financial expertise to help make things happen is what we do. The strong support, engagement and number of partnership investments under development that we have with the states, territories, local councils and private sector organisations is testament to the benefits of strengthening the capability of the Commonwealth as an infrastructure partner.

As a taxpayer and a citizen, this gives me greater confidence that my infrastructure investment will deliver maximum returns; returns in terms of outcomes and, if possible, recycling some or all of my investment back into other national infrastructure projects. Of course, I would say that from where I sit, but I hope in time as these initiatives are delivered, my fellow taxpayers and citizens will share this confidence.

www.infrastructuremagazine.com.au September 2018 // Issue 8 27

INVESTMENT

JOIN INFRASTRUCTURE EXPERTS AT

ASSET MANAGEMENT FOR CRITICAL INFRASTRUCTURE

12-13 September

Swissötel Sydney

TThe

2018 Asset Management for Critical Infrastructure Conference is set to kick off on 12 September for two days of in-depth discussions

about the most pressing issues in the management of critical assets.

he full speaker lineup and program has been released, with experts from water and power utilities, government, industry associations and consultancies.

AN IN-DEPTH LOOK AT THE CURRENT STATE OF ASSET MANAGEMENT

Day One of the conference will see thought-leading individual presentations on:

♦ Learnings from the implementation of ISO 55001 at Sydney Water

♦ Changing asset management requirements in the energy sector due to rapid sector transformation

♦ Case studies exploring how to optimise cost against risk

♦ Leveraging data with digital twins and IoT techniques

♦ The future skills required of asset managers

♦ Incorporating sustainability into asset management systems

♦ New state asset management strategies for New South Wales Day Two’s keynote presentation explores how to develop strategic asset management plans and overcome current challenges, before the conference is split into four targeted streams on asset management in the rail sector, corrosion, renewable infrastructure and trenchless technologies. These specialised streams will run

as moderated panel sessions with key senior figures from each area providing delegates with information specific to the asset management challenges and solutions for that topic.

The conference is then rounded out with a Super Panel which brings back the speakers from across the two days to summarise some of the key discussions and answer any burning questions from attendees.

Asset Management for Critical Infrastructure 2018 is the key asset management event across the utility and infrastructure sectors; nowhere else will delegates have the chance to look in-depth at these issues and learn how other sectors are overcoming challenges.

EXHIBITION AND NETWORKING OPPORTUNITIES

In addition to the conference presentation and panel sessions, the event also features an exhibition showcase where delegates will see up close some of the newest innovation technologies, products and services that are changing the way critical assets are managed.

The conference and exhibition has been designed to allow for lots of networking between like-minded attendees. There are several speed networking sessions which are a structured and fun activity that gets conversations flowing and guarantees

delegates will make new industry connections. This is in addition to opportunities during the breaks and the networking drinks at the end of Day One.

BONUS STAKEHOLDER MANAGEMENT WORKSHOP

Conference MC Steve Doran will also be co-hosting the workshop Beyond Stakeholder Management: Influencing the relationships that can make or break your project with Mirella Di Genua, Owner of Tre Sorelle Trading, on 11 September at Swissôtel Sydney, the day before Asset Management for Critical Infrastructure begins.

This full-day workshop is a great addition to the conference and will equip delegates with the tools and insights to effectively influence the identified relationships that have a vital bearing on asset management project outcomes. To register for the workshop, head to www.assetmanagementevent.com.au/ workshop-and-conference.

September 2018 // Issue 8 www.infrastructuremagazine.com.au

28 ASSET MANAGEMENT

To register for Asset Management for Critical Infrastructure 2018, visit www.assetmanagementevent.com.au.

Steve Doran Director, Infrastream Chair, Sydney Chapter of the Asset Management Council

David Singleton Independent Director/Chair Infrastructure Sustainability Council of Australia

Bonnie Ryan Senior Manager GS1 Australia

Andrew O’Connor Partner, Engineering and Asset Management KPMG Australia

assetmanagement FOR CRITICAL INFRASTRUCTURE

12–13 September 2018 | Swissôtel Sydney

Rami Affan Executive Director, Asset Management Infrastructure NSW

Dr Lutfiye Manli Senior Asset Management Strategy Advisor Powerlink Queensland

Andrew Jones Senior Asset Integrity Engineer CNC Project Management

Darren Davis General Manager, Asset Management & Engineering Snowy Hydro

Gerard Reiter Executive Manager, Network Planning & Operations TransGrid

Mark Simister Head of Delivery Management Sydney Water

Mina Gerguis Manager, Asset Portfolio Victorian Health and Human Services Building Authority

Iain Pople Head of Asset Management Edify Energy

Kerry Brown Professor of Employment and Industry Edith Cowan University

Brad Dockrill Partner/Director Vinsi Partners Consulting Engineers

Louis de Groot Project Manager, Sustainable Infrastructure Solutions Unitywater

Paul Higham Head of Service Planning & Asset Strategy Sydney Water

Dr Carla Boehl Principal Consultant SNC-Lavalin

Simon Krismer Principal Consultant Krismer Consulting

Andrew Meier Executive Director/CEO Australian Centre for Rail Innovation

Kirsty Bauer Case Manager Infrastructure Sustainability Council of Australia

Jim Hickey Electrolysis Engineering Officer, Network Test and Measurement Ausgrid

Scott Stevens Principal Engineer Civil, Operations & Service Delivery Queensland Urban Utilities

Favotto Asset Planning Manager Transport for NSW

Martin Marerwa Senior Asset Investment Planner, Asset Investment Planning Metro Water Corporation

Supporting organisations

Di Genua Owner Tre Sorelle Trading

www.infrastructuremagazine.com.au September 2018 // Issue 8 29 ASSET MANAGEMENT assetmanagementevent.com.au assetmanagementevent.com.au

Lucio

Mirella

RUGGED TABLETS SMOOTHING OUT ROAD IMPROVEMENT PROJECTS

by Brett Gross

AIt can be frustrating when roads are in disrepair – or under constant repair. That is why Main Roads Western Australia is keeping one of the most widely geographically distributed road networks in the world in top shape for the millions of people and billions of dollars and goods that traverse the region every day.

s the state road authority, Main Roads WA is responsible for building, inspecting and maintaining more than 18,500km of main roads and highways covering over 2.5 million square kilometres. It’s no easy feat by anyone’s standards. Yet, this government-affiliated agency has found a way to simplify one of the most complex jobs in the public sector while simultaneously raising the bar for road quality standards for the world using just rugged tablets.

A little over five years ago, each Main Roads WA regional office was using its own system to document road inspections and track repair progress. The problem was that most of these systems were heavily reliant on paper-based documents or Toughbook notebooks that could not be safely mounted in vehicles.

Considering the sheer number of resources it requires to coordinate field-based teams, much less execute and track the high volume of projects in the works on any given day, these legacy “systems” were failing fast.

CONSOLIDATING WORKFLOW SYSTEMS

After doing its research about alternative technology-based workflow solutions and conducting extensive field tests, Main Roads WA realised that rugged tablet-based solutions were the best way forward. By giving every worker an Xplore rugged tablet, this transport authority was able to migrate its seven regional offices onto the same agency-wide workflow system. Everyone was able to login to the same software applications to manage assets, record, track road maintenance issues, and retrieve job requirements, whether they were on-site, on the road, or in the office.

By using mobile technology to directly improve the quality of its data management, Main Roads was able to improve the performance of its maintenance and inspection management systems and, therefore, improve the quality of the region's roads.

INCREASING WORKFLOW CONTINUITY

Main Roads WA is a great model for every public and private sector organisation to follow, especially those with highly mobile workforces charged with managing disparate transportation fleets or infrastructure assets. It is highly inefficient and certainly not cost-effective to invest in multiple devices, and therefore multiple software platforms and configurations, to deliver critical workflows to every employee and job site. You would not give one employee two different desktop computers, so why give them multiple computers at all?

As Main Roads WA can advocate, today’s government, transportation and field-based agencies – especially those responsible for building and maintaining infrastructure – need a single mobile computing platform for workflow continuity between the traditional office, the vehicle and the field.

That requires some strategy and planning, as not all mobile computers are going to be well-suited for your workflow software. There are always other considerations when deploying mobile technology on the road, with safety being the primary one.

However, with the right mobile tools in place, both government-affiliated organisations and private sector companies can improve worker productivity – which accelerates project timelines, making your customers happy – and eliminate wasteful operational expenditures, which is especially critical when taxpayer dollars are driving these projects.

September 2018 // Issue 8 www.infrastructuremagazine.com.au 30 ASSET MANAGEMENT // PARTNER SOLUTIONS

MAKE THE SMART RUGGED CHOICE

Protect Your Most Important Assets with These Field-Proven, HazLoc-Certified Mobility Solutions

Xplore’s powerful mobile devices are engineered from the inside out to survive common environmental hazards and hostile field conditions.

Whether you are responsible for paving new roads, inspecting new buildings, repairing railroad tracks, or maintaining utility infrastructure, Xplore’s mobile computers will stay by your workers’ sides to help them effectively plan their day and power through mandatory logistical and compliance tasks without error.

Learn more about the benefits you gain when you build your mobility solution upon Xplore’s rugged tablet, handheld or 2-in-1 mobile computer.

Built for Rugged Extremes Power of Intel ® Core Real-time Data Communications Outdoor Viewability C1D2 / ATEX Protection Peripheral Connectivity OS Application Flexibility www.xploretech.com/infrastructure

MOBILITY AS A SERVICE IN AUSTRALIA: CUSTOMER INSIGHTS AND OPPORTUNITIES

by Susan Harris, CEO, ITS Australia

There’s much discussion these days about once-in-a-generation change; digital disruption, major demographic and societal shifts, and mega-projects offering improvements unimagined by our grandparents or sometimes even our parents.

What has not been seen before though is the kind of unprecedented potential for change in transport that we are currently experiencing.

During interviews with more than 80 leaders in the transport and technology sectors, across government, industry and academia, a strong theme emerged; that not since the mass production of private vehicles around 1920 has there been such potential for revolutionary change in the transport sector.

Transport innovation like ‘Mobility as a Service’, or MaaS, offers the potential to drastically improve customer choices, reduce travel costs, increase network capacity and transport sustainability while improving social and environmental outcomes.

While the mass production of private vehicles obviously had a stunning impact on society and the built environment, the advent of connected and automated vehicles and other revolutionary technologies offer the potential for even greater levels of disruption. Concepts like MaaS are ways we can adapt to, and positively leverage, this societal and technological disruption.

This research project was led by ITS Australia and made possible with support from project partners through the iMOVE CRC. Project partners were supported by a Steering Committee of industry and government experts from the following organisations collaborating on the project and providing invaluable advice and input: Cubic; Department of Infrastructure; Regional Development and Cities; HMI Technologies and Ohmio; GHD; Keolis Downer; MaaS Australia; PTV; RACV; and Transdev.

With these organisations and our project partners, and the perspectives gathered through extensive interviews, a robust discrete choice customer survey instrument was designed to test the thoughts and expectations of a demographically representative sample of Australians.

PROJECT GOALS AND METHODOLOGY

As found in the recent Transport for London report, Attitudes towards car-ownership and MaaS, both Londoners and Australians strongly prefer a MaaS product that includes public transport. This indicates how important it is that relevant authorities explore how public and private offerings can be integrated effectively.