Fitzroy

Top eight

to improve your pump’s energy efficiency PLUS the Industry Capability Guide Your guide to the industry’s leading providers in 2022 OIL MINING IRRI VAC WAS i OIL SAG TIONAIRRIG HV TERASTEWA MANUF CTURING PUMP INDUSTRY CAPABILITY GUIDE 2022 ISSUE 37 pumpindustry SPRING 2021

River Water’s flow prediction tool for variable speed pump stations

ways

AGRICULTURE

n:

MINING

ENERGY MUNICIPAL MILITARY The Trusted Choice For Use I

Hello all and welcome to the Spring Edition of Pump Industry Magazine the official voice of Pump Industry Australia, and thanks to those few who pointed out to me that the last edition mistakenly read the Autumn Edition - as if we would want to go through winter again.

I would like to say that with the advent of spring everything should be looking up, but am forced to admit that 2021 is turning out to be no better than 2020, as the recent outbreaks of the Delta variant across Australia and now New Zealand has introduced a high degree of uncertainty to the outlook for the second half of the year.

time to review and update what you currently have. Discount is available for bulk purchases.

Some information that will be of interest to QLD Members is that a subcommittee of PIA has approached the QBCC with a view to getting a better understanding of the QLD Legislative Acts defining works related to water and sewage installations and repairs covered by the Plumbing and Drainage Act 2018 (PD Act).

Pump Industry Australia Incorporated C/-340, Stuarts Point Road

Yarrahapinni NSW 2441 Australia Ph/Fax: (02) 6569 0160 pumpsaustralia@bigpond.com www.pumps.org.au

PIA Executive Council 2020

John Inkster – President Brown Brothers Engineers

James Blannin – Vice President Stevco Pumps & Seals

Kevin Wilson – Treasurer/Secretary Executive Officer

Alan Rowan – Councillor Executive Officer – Publications and Training, Life Member

Ken Kugler Executive Officer – Standards, Life Member

Geoff Harvey – Councillor Irrigation Australia Limited

Anant Yuvarajah – Councillor ASC Water Tanks

Joel Neideck – Councillor TDA Pumps

Matt Arnett – Councillor Ebara Pumps Australia

Michael Woolley – Councillor Tsurumi Australia

Steve Bosnar – Councillor Pioneer Pumps

Billie Tan – Councillor Regent Pumps

The pathway to improved work and lifestyle beyond the pandemic is vaccinations. Unfortunately, distribution and vaccine hesitancy have been major issues to getting the vaccine. Hopefully we will see new supplies speed up the rollout, reducing the frequency and severity of lockdowns. However, the recent outbreak will depress economic activity in the September Quarter, resulting in negative growth of somewhere between zero and one per cent instead of increasing by a similar amount. We know the Australian economy is quite resilient and hopefully we will see the economy rebound in Q4 as vaccinations increase and restrictions ease as it has done after previous lockdowns. The key is getting the vaccinations up to the 70 per cent or 80 per cent threshold so we can do away with lockdowns and open up both the economy and the country’s borders.

Meanwhile on the domestic front, PIA activities have been very subdued because of the current lockdowns. It is hoped we can hold another of our Pumps & Training Systems Courses in Perth in September, COVID permitted, so for all our WA Members please watch the Thursday weekly news releases from Monkey Media for more information. The July breakfast seminar planned by DAB Pumps Oceania in Melbourne was postponed.

You may have noticed recently in Monkey Medias’ weekly newsletter reference to our two Handbooks specifically designed for the Australian pump industry – the Australian Pump Technical Handbook and the Australian Pipe Friction Handbook, both in their fifth editions. These publications are industry standard reference volumes for those who work or are associated with the pump industry including consultants, designers, manufacturers, distributors, operators, users and educators. Both these publications have been recently updated so now might be a good

Our belief is that the Legislation relates more to the public health arena rather than mining, petrochemical, industrial process, marine, energy, stock water, irrigation, fire protection, golf courses, etc. but we seek further clarity regarding water and sewage work.

As you know, our industry consists of several hundred small to large enterprises employing thousands of people across the sector and this matter is extremely important to them. The initial response from the QLD Government to our request was both positive and helpful; we understand that this dialogue has a long way to play, but PIA will keep you up to date with events as they occur.

As the opportunity allows and we see a return to some form of normality, we plan to run two or three seminars in the coming months on topics of interest to the industry. In the meantime, please feel free to put forward any topics or discussion points you would like to see raised.

Even in these difficult times we are fortunate to be able to stay connected through our Pump Industry Magazine, which continues to be well subscribed to, providing excellent editorial and coverage of newsworthy events in our industry. In addition, there is the weekly e-newsletter which provides you with all the latest news and developments as they occur. I trust you find the quarterly magazine and the weekly news releases as a great way of remaining connected to the industry at large and a distinct benefit of your membership.

At the time of writing NSW, VIC and NZ were all in lockdowns, so I am hoping that by the time you get to read this edition the lockdowns will be lifted, the vaccination rates approaching the 70 per cent mark and we start to see some light at the end of the tunnel and a return to see some sort of normalcy. So for the good of all the community please get vaccinated and stay safe.

Best Regards

John Inkster President

2 pump industry | Spring 2021 | Issue 37 www.pumpindustry.com.au PRESIDENT’S WELCOME

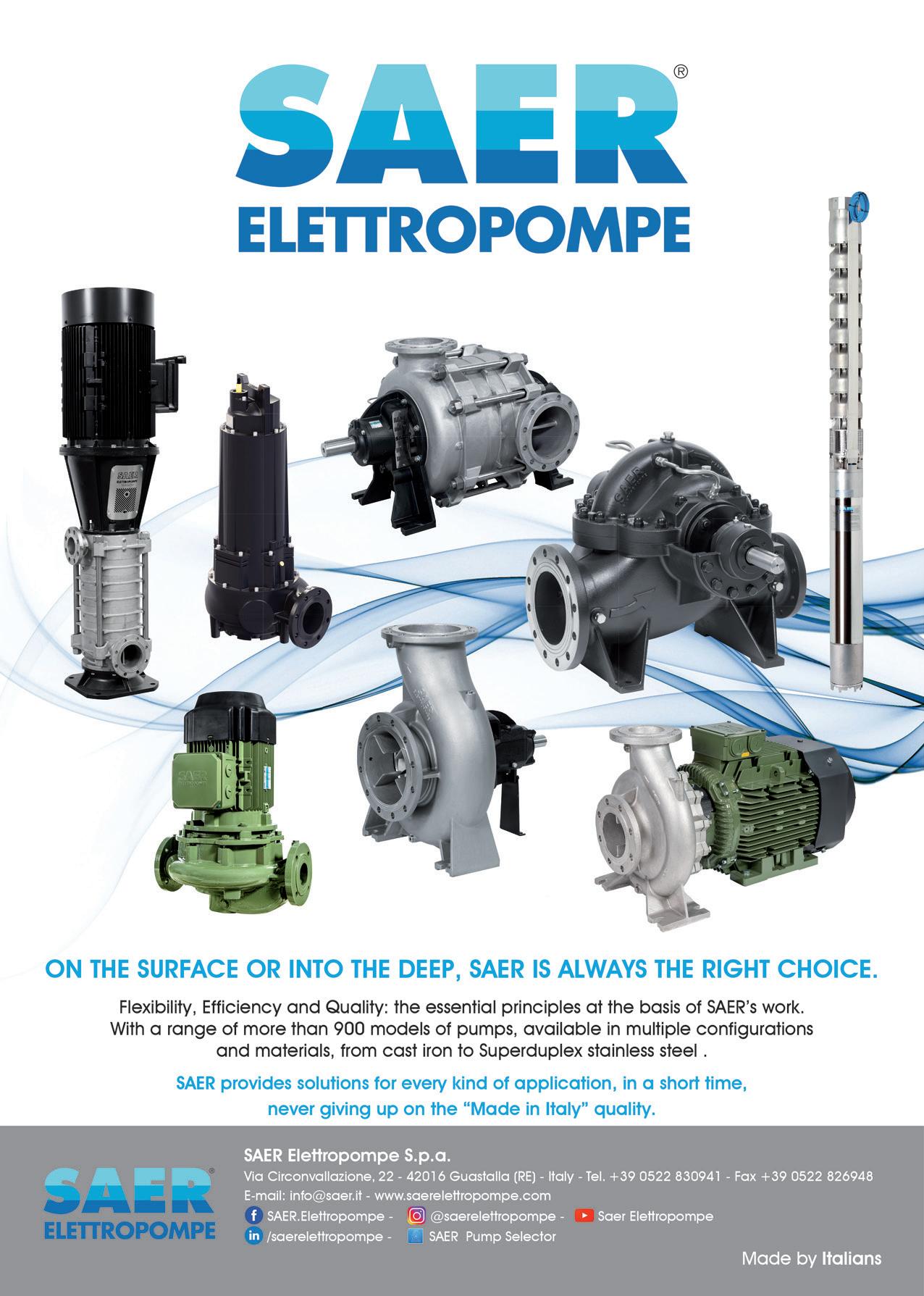

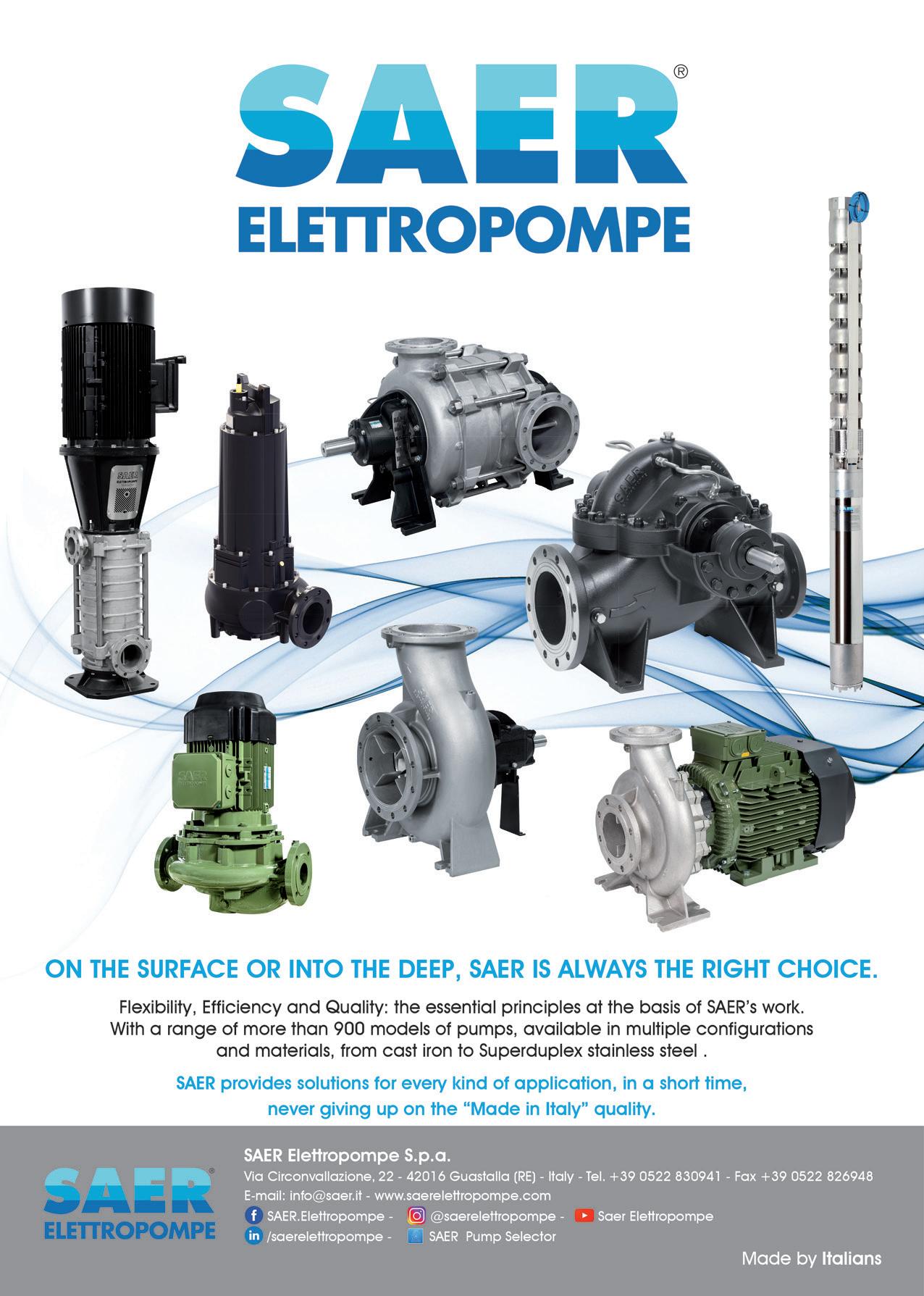

Hygienic Pumps & Mixers.

At Inoxpa, our focus is on ensuring the quality and suitability of our products (mixing skids, CIP skids, product recovery systems, pasteurizers, manifolds, process automation, pumps, agitators, blenders, mixers, valves and fittings) for each industry.

Stainless steel, sanitary centrifugal, rotary lobe and progressive cavity pumps, hygenic agitators and mixers for:

Dairy

Food and beverage

Chemical

Cosmetic

Pharmaceutical

Experience. Innovation. Quality. Reliability.

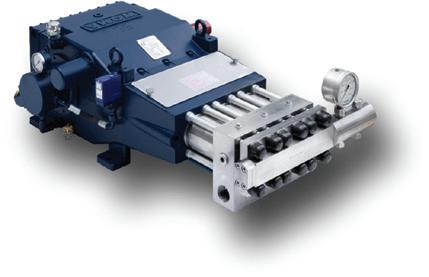

At Hammelmann Australia, our primary focus is on delivering customer-specific solutions for pumping high pressure liquids and gases in diverse applications and industries:

Offshore platforms

HPUs

FPSOs

Mining and minerals

Chemical Petrochemical Ship cleaning

Construction

Our positive displacement high pressure process pumps are used for a variety of industrial uses:

Chemical injection

Sea water reinjection

Flowline services

Dosing

Published

ABN: 36 426 734 954

C/- The Commons, Office 1, 36-38 Gipps St, Collingwood VIC 3066

P: (03) 9988 4950

F: (03) 8456 6720

monkeymedia.com.au

info@monkeymedia.com.au pumpindustry.com.au magazine@pumpindustry.com.au

Editor: Lauren Cella

Client Services Manager: Stephanie Di Paola

Business Development Manager: Rima Munafo, Jacob Trad

Design Manager: Alejandro Molano

Designers: Jacqueline Buckmaster, Danielle Harris, Luke Martin

Publisher: Chris Bland

Managing Editor: Laura Harvey

ISSN: 2201-0270

PIA NEWS

PIA MEMBER

CONTENTS This magazine is published by Monkey Media in cooperation with the Pump Industry Australia Inc. (PIA). The views contained herein are not necessarily the views of either the publisher or the PIA. Neither the publisher nor the PIA takes responsibility for any claims made by advertisers. All communication should be directed to the publisher. The publisher welcomes contributions to the magazine. All contributions must comply with the publisher’s editorial policy which follows. By providing content to the publisher, you authorise the publisher to reproduce that content either in its original form, or edited, or combined with other content in any of its publications and in any format at the publisher's discretion. NEWS Mitiamo pipeline project reaches completion 6 $77 million for Rockhampton water and sewerage infrastructure ........... 7 New pump station to be constructed for $3.5 million project ................. 8 $20 million federal funding to improve TAS water security 9

Australian Pipe Friction and Pump Technical Handbooks: vital resources for pump professionals ................................................... 12

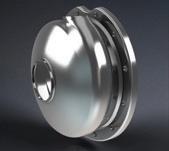

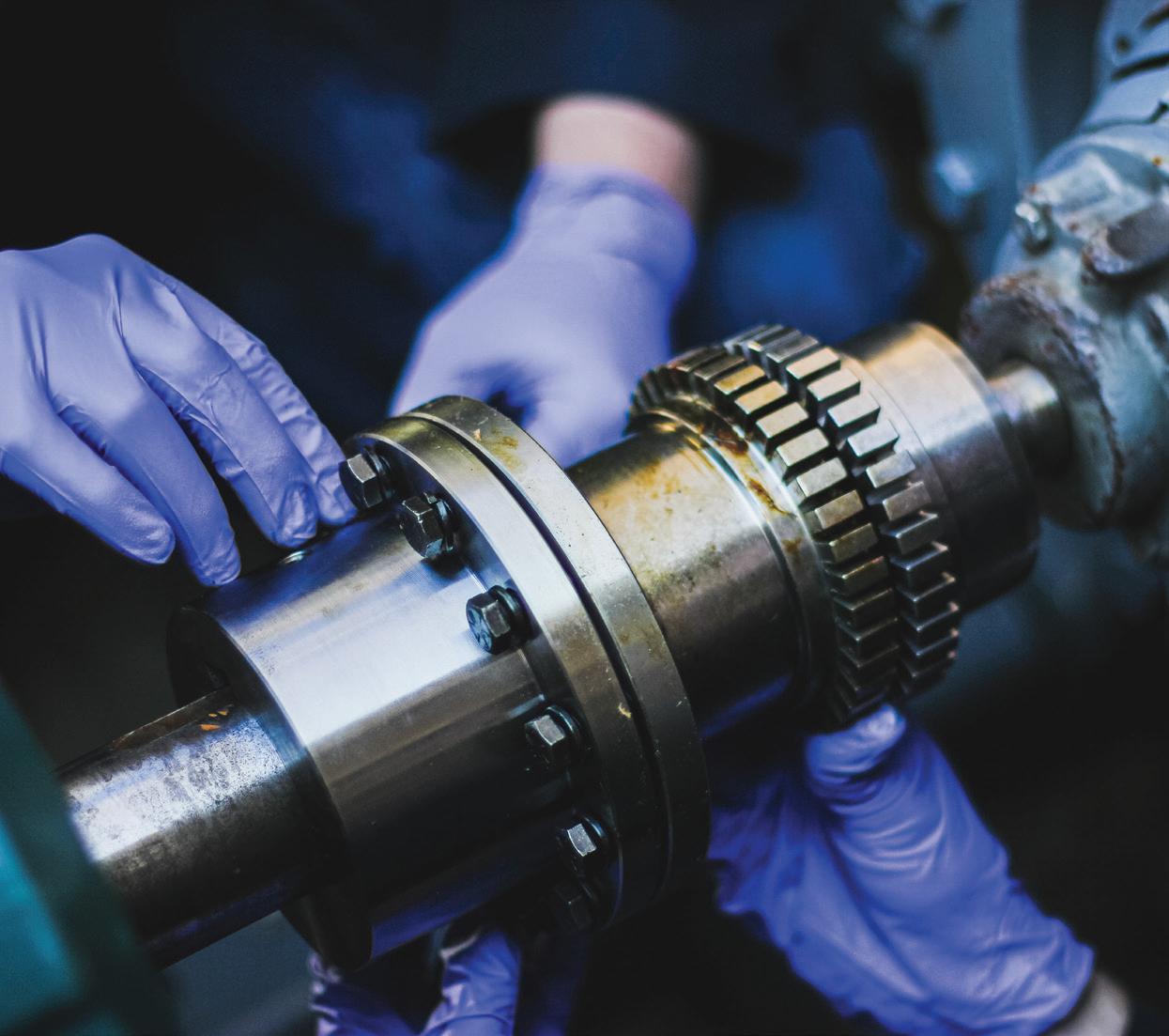

The future of booster set technology 14 Perkins® My Engine App: taking service and capability to a new level 16 Hydroforming Process: world-first technology ...................................... 18 Flexidrag® – the premium drag hose for your broad acreage irrigation 20 Cover image highlights our article in the Industry Capability Guide about the basics of pump types, and operation and maintenance. Fitzroy River Water’s flow prediction tool for variable speed pump stations Top eight ways to improve your pump’s energy efficiency

PLUS the Industry Capability Guide Your guide to the industry’s leading providers in 2022 PUMP CAPABILITY 2022 ISSUE 37

NEWS

pumpindustry

by Monkey Media Enterprises

SMART PUMPS

5 www.pumpindustry.com.au pump industry | Spring 2021 | Issue 37 pumpindustry INDUSTRY NEWS Austworld advancing Australian-based facilities ...... 22 Major acquisition creates Australia’s largest pump rental company 24 Temporary solution for a wastewater plant............... 26 What to look for when purchasing positive displacement pumps 28 ENERGY EFFICIENCY Top eight ways to improve energy efficiency in pumps......................................... 30

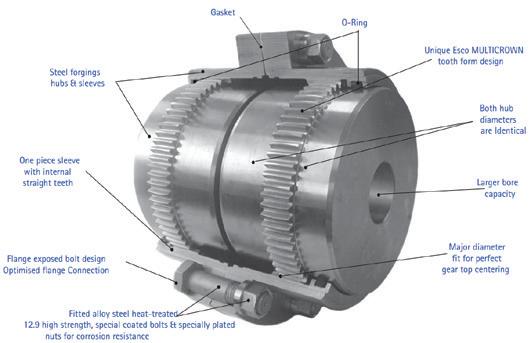

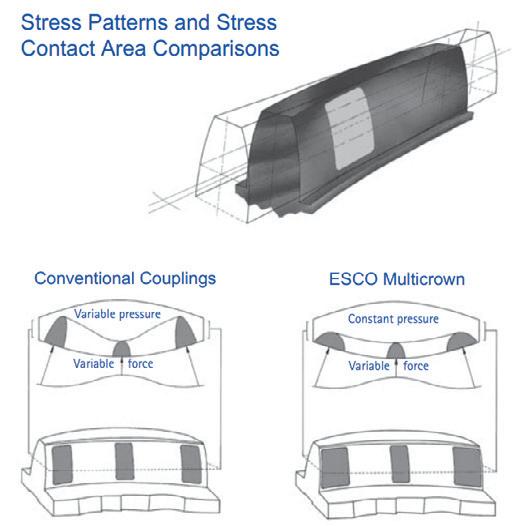

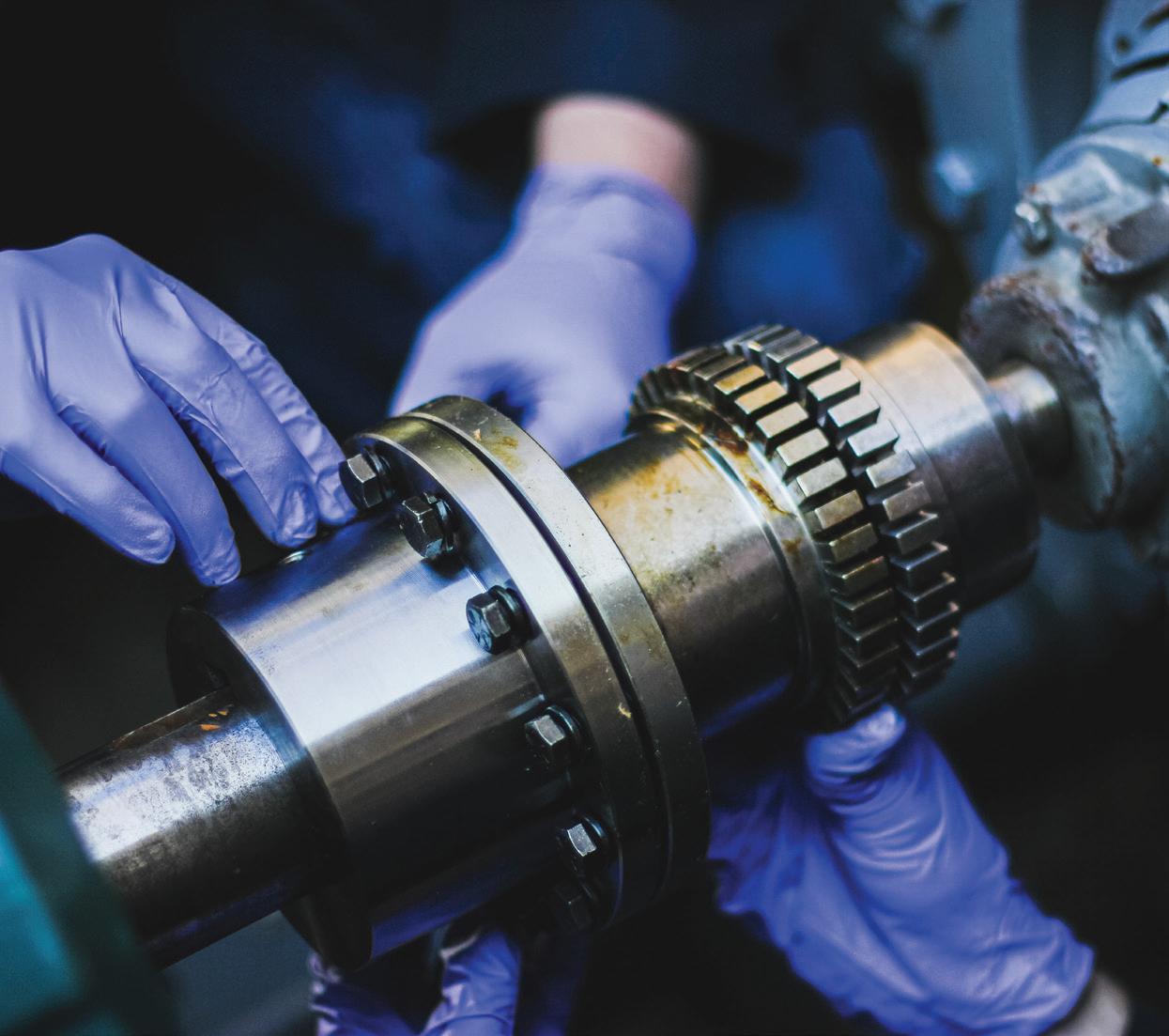

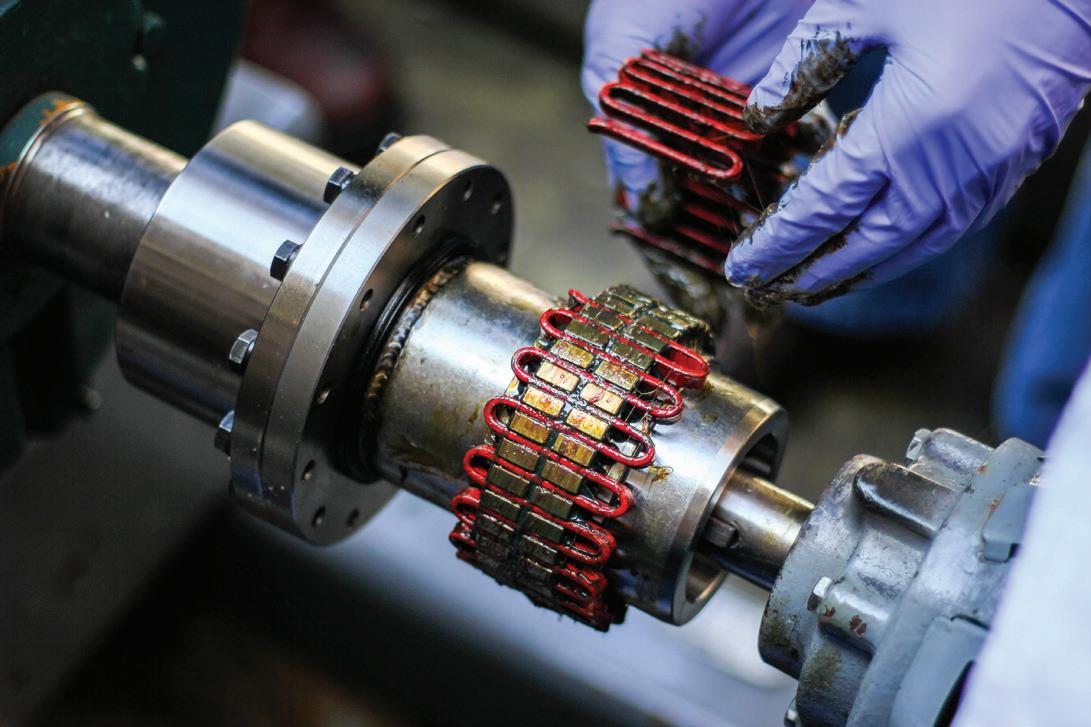

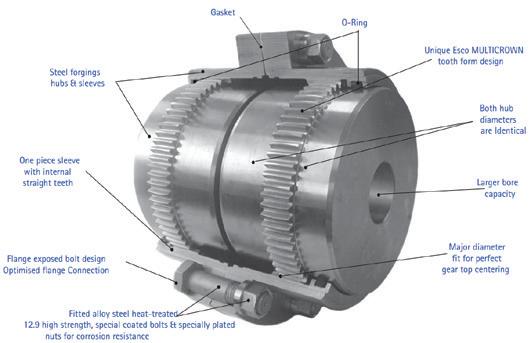

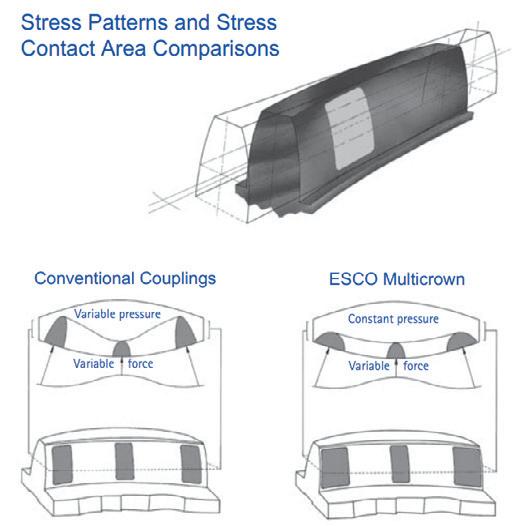

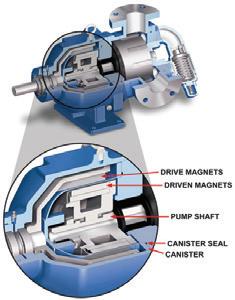

Efficient priming and Anti-Spit technology: AllightSykes’ recipe to the smart pump .................... 34 Flow prediction tool for variable speed pump stations 36 Pump Genius ............................................................... 40 COUPLINGS ESCO flexible gear couplings with Multicrown tooth form for longer life from Drive Systems 42 Flexible coupling selection for improved pump and motor efficiency and operation 44 TECHNICAL: Successful project management (Part 4) 48 REGULARS: President’s welcome 2 Ask an expert: This edition of Ask an Expert will look at digitalisation and its influence on the pump industry 52 PUMP SCHOOL: Magnet Drive Pumps 54 Editorial schedule 56 Advertisers’ index ....................................................... 56

Mitiamo pipeline project reaches completion

The Federal and Victorian Governments have announced that the Mitiamo Pipeline Project has been completed, supplying more reliable water supply and less water evaporation to irrigators across the state.

Deputy Prime Minister and Minister for Infrastructure, Transport and Regional Development, Barnaby Joyce, said the completion of the Mitiamo and District Water Supply project came as part of the $3.5 billion National Water Grid which aims to secure Australia’s water future.

“This project is fantastic news for the local economy which is strongly backed by agriculture, with project construction also having supported 170 jobs here in regional Australia,” Mr Joyce said.

The completed project includes 300km of new pipeline which will supply a new district covering in excess of 58,000 hectares of land north of Bendigo and southwest of Echuca, helping to provide a year-round service to around 170 rural properties.

Historically, more than 80 per cent of water supplied via the channels in the region is lost before use and only two-thirds of the project area is currently serviced, with farmers incurring high water cartage costs.

Victorian Acting Water Minister, Richard Wynne, said the project will reduce public and private water losses by more

than 1,000ML per year by replacing the old leaking channel with pipes, a pump station and 85ML storage facility to provide year-round water supply.

“A lack of reliable, quality water has constrained the expansion of agriculture in the Mitiamo region – this project will address this and help farming grow in northern Victoria,” Mr Wynne said.

Water saved will be used to improve the health of rivers and wetlands in line with Victoria’s obligations under the Murray Darling Basin Plan, with no socio-economic impacts.

Federal Member for Mallee, Anne Webster, said with around a gigalitre of water savings to be achieved each year, the completion of this project allows farmers to invest with certainty for the future.

“This is a fantastic project that will support agricultural benefits for farmers through improved stocking rate and livestock productivity,” Dr Webster said.

“The completion of this project is great news for the local communities, as it will provide a secure and stable water supply.”

The Mitiamo and District Water Supply Project received $14.5 million from the Federal Government, $10.2 million from the Victorian Government and $4.3 million from Goulburn Murray Water.

THE INTELLIGENCE OF THE PUMP PUMP MONITOR

Pump Monitor turns the progressive cavity pump into an intelligent fi eld device.

NEWS pump industry | Spring 2021 | Issue 37 www.pumpindustry.com.au 6

Performance analysis to optimize the pump and process Alarm notifi cation Process protection through continuous monitoring Transparent pump performance Optimized operating costs

SEEPEX Australia Pty. Ltd. T +61 2 43554500 info.au@seepex.com www.seepex.com

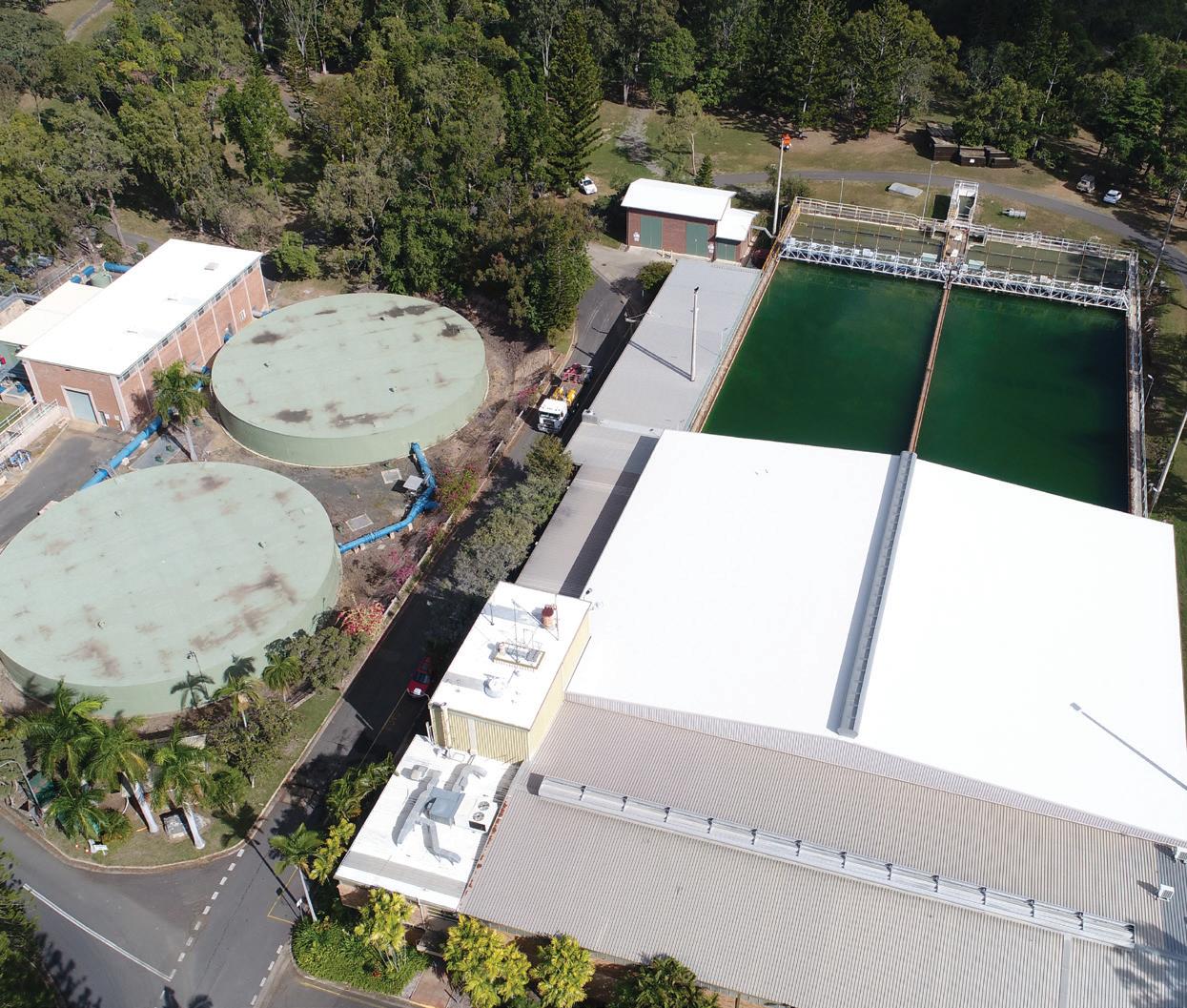

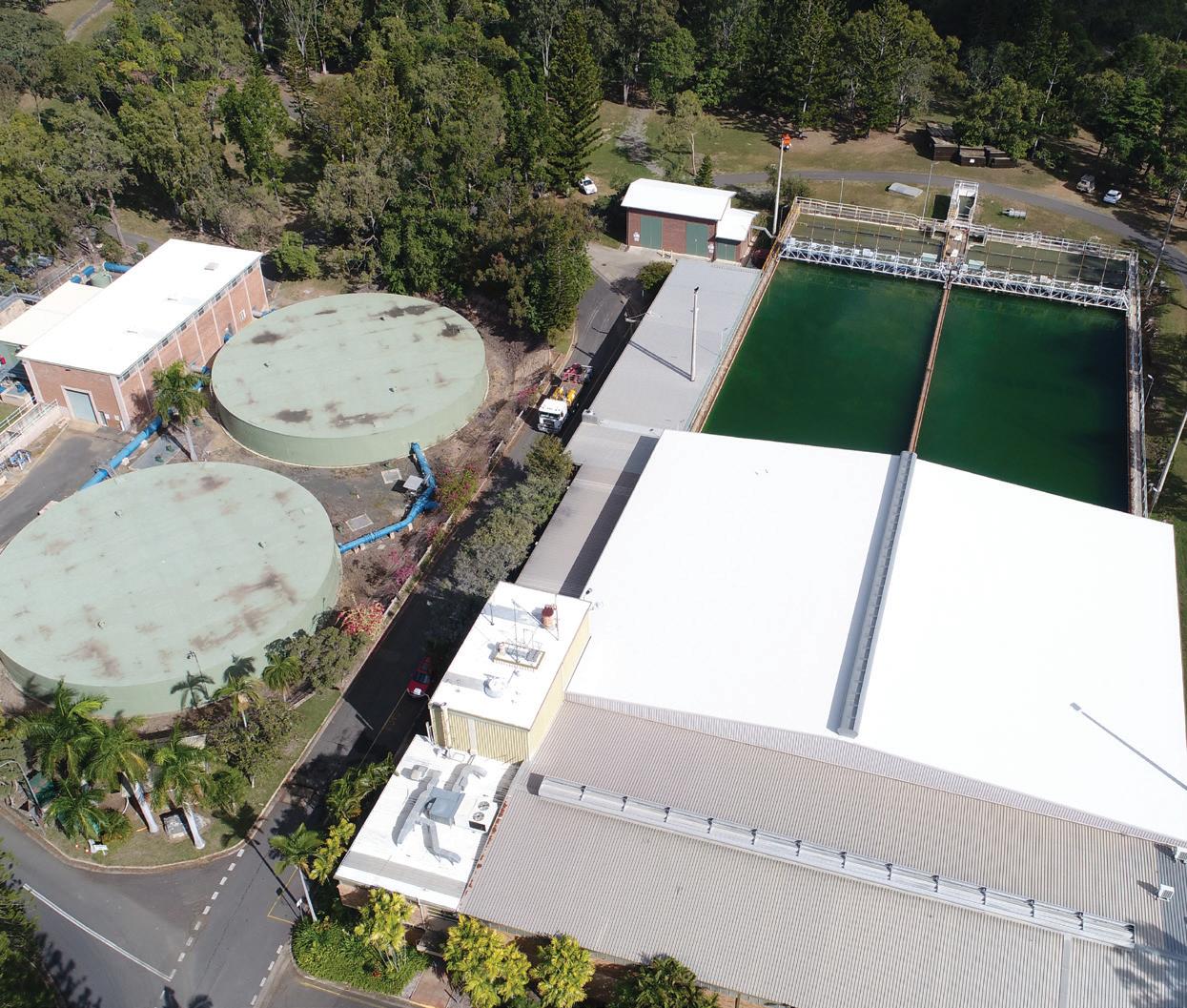

$77 million for Rockhampton water and sewerage infrastructure

Rockhampton Regional Council has allocated $77 million over the next three years for water and sewerage infrastructure in its latest Budget.

Rockhampton Mayor, Tony Williams, said the next three years would see the Council invest heavily in essential infrastructure so that the services are in place for more housing, more industry and more people calling Rockhampton home.

“This Budget contains a major investment in three catalyst infrastructure projects – the North Rockhampton Sewage Treatment Plant (NRSTP), the Gracemere Sewage Treatment Plant (GSTP) and the Glenmore Water Treatment Plant (GWTP),” Mr Williams said.

“These projects are the key to unlocking a bigger and better Rockhampton because they allow us to service an additional 16,000 homes.

“Without them, we’ll find ourselves constrained to grow substantial new housing development in as little as three years.

“At the same time, economic modelling predicts these projects will create a benefit to the local economy with 300 local jobs generated and $107 million added to the local economy.

“We have already received some support from other levels of government towards these projects but, given the cost and the benefits they will deliver to our region, we will keep talking to them to see how we can partner on these projects going forward.”

Rockhampton Water Councillor, Donna Kirkland, said these upgrades would deliver not just bigger services, but better ones.

“As part of the sewage treatment plant upgrades, we’ll be changing the style of aeration during the treatment process,” Ms Kirkland said.

“This will mean that the process of treating the sewage is more effective and energy efficient resulting in lower energy cost.

“These three projects are all at different stages with the NRSTP design completed and set to go to tender in the coming months for commencement of construction before Christmas.

“The Gracemere STP project will commence a detailed design stage in the coming months and the Glenmore WTP

Upgrade Project is already underway with the project awarded to Alliance Automation for the completion of a design and construct project.

“Expenditure on all three projects is expected to ramp up significantly over the next 12 months.

“About 65 per cent of the connected population in Rockhampton relies on the NRSTP day in, day out, and it is approaching its design capacity now.

“That’s why we’ll be looking at progressing this one first, with the

upgrades set to increase capacity by 50 per cent, meaning it will be able to service 75,000 people alone.

“I’m also very pleased that these projects will drive better environmental outcomes – less nutrients and effluent will go back into the environment, reduced carbon dioxide emissions through energy efficiency gains, and we expect to see more opportunities for reuse of treated water in irrigation.”

Thousands of Pumps Have Never Seized Thousands of Pumps Have Never Seized Yonkers, NY USA Pumps fitted with GRAPHALLOY® wear parts survive upsets. • Run dry and keep running • Self-lubricating • Non-galling • Won’t swell • Corrosion resistant • Dimensionally stable • Improved efficiencies • -400˚F to 1000˚F (-240˚C to 535˚C) +1.914.968.8400 • www.GRAPHALLOY.com GRAPHITE METALLIZING CORPORATION Graphalloy_Pumps_122x185mm.qxp_Layout 1 2/10/21 10:53 AM Page 1 7 www.pumpindustry.com.au pump industry | Spring 2021 | Issue 37 NEWS

New pump station to be constructed for $3.5 million project

Construction of a new sewage pump station at Hallidays Point began in early August as part of a $3.5 million project that aims to increase the operational efficiency of the region.

The new pump station will allow for sewage to be diverted from a number of nearby pump stations and transferred directly to the Hallidays Point Sewage Treatment Plant via a new rising main.

The New South Wales Midcoast Council’s Director of Infrastructure and Engineering Services, Rob Scott, said,

“This will reduce the volume of sewage the existing pump stations are required to process, giving our system more local capacity.

“As a result, we won’t need to upgrade these pump stations to keep up with future growth in the area, and there’ll also be less chance of any sewage overflows occurring during wet weather events.”

Mr Scott said a permanent generator would also be installed at the new pump station to protect against power outages, and an odour control system would be put in to ensure the community didn’t experience any unwanted odours.

While the work will take place close to Blackhead Road, there will be minimal disruption to traffic or the community.

The project is expected to be completed by March 2022.

Layne Bowler vertical turbine and submersible pumps have a proven record under the most demanding and toughest of conditions.

VERTICAL TURBINE PUMPS

• Flows to 7,500 L/Sec

• Heads to 500 m

• Power to 1000+ kW

• Temperatures to 150°C

• Bowls Diameter up to 45 inch

Applications

• Irrigation

• Water supply

• Process water

• Geothermal

• Cooling towers

• Fire protection

• Marine

• Water treatment

• Dewatering

SUBMERSIBLE PUMPS

• Flows to 140 L/Sec

• Heads to 200 m

• Power to 110 kW

• Bowls Diameter in sizes 6”, 7”, 8” and 10”

Applications

• Irrigation

• Deep well water supply

• Inline booster

• Service water

• Dewatering

Brown Brothers Engineers have innovative solutions whatever your application. Contact us today about your requirements.

NEWS pump industry | Spring 2021 | Issue 37 www.pumpindustry.com.au 8

DELIVERING PUMPING SOLUTIONS Ph: 1300 4 BBENG www.brownbros.com.au 05/21

$20 million federal funding to improve TAS water security

As part of the $108 million National Water Grid Connections funding pathway, the Tasmanian Government has received $20 million in federal funding for four water projects to improve water quality and efficincy, including upgrades to sewerage pump stations, and water and irrigation scheme expansions.

These four new projects will each receive $5 million of federal funding to deliver enhanced water reliability while also promoting regional economic growth and sustainability.

The successful projects are:

• $5 million for the augmentation of the Greater Meander Irrigation Scheme

• $5 million for Shellfish Lease Water Quality Improvement Program to upgrade sewerage pump stations close to shellfish lease areas

• $5 million for an expansion of the Penna Recycled Water Scheme

• $5 million for the South Arm Recycled Water Pipeline, which is a reuse scheme to deliver irrigation water to the South Arm Peninsula

The National Water Grid Connections initiative is designed to deliver the construction of smaller-scale projects to provide short-term economic stimulus, and to support primary production and unlock potential in regional communities.

Up to $20 million was made available for each state and territory to deliver projects over the next two years, with an Australian Government contribution of up to $5 million per project.

Assistant Minister for Industry Development, Jonno Duniam, said the Government was delighted to support the

South Arm Recycled Water Pipeline in Tasmania, which will transfer water from Blackmans Bay Water Treatment Plant to the South Arm Peninsula.

“The pipeline will improve the resilience and reliability of South Arm’s water infrastructure, ensuring a stronger future for water security across the region,” Mr Duniam said.

“It will strengthen the local economy of South Arm, support agricultural production and lead to new investment in economic activities in the region.”

Deputy Prime Minister and Minister for Infrastructure, Transport and Regional Development, Barnaby Joyce, said through this funding pathway, the Australian Government is investing in packages of water infrastructure projects brought forward by states and territories right across the country to improve water reliability and efficiency.

“The National Water Grid Connections is all about driving the construction of smaller-scale projects over the next two years to provide short-term economic stimulus,” Mr Joyce said.

“The cumulative impact for the National Water Grid will be significant. Collectively, these projects are expected to support over 7,000 hectares of irrigable land and connect 400 new customers. An additional 13,000 customers are expected to benefit from improved water access or reliability.

“Up to 1,175 jobs will be supported during construction, with over 2,550 ongoing and up to 500 more seasonal jobs set to be created nationally.

“The $3.5 billion National Water Grid Fund is paving the way to national water security, while promoting local economic activity and job creation along the way.”

NEWS 9 www.pumpindustry.com.au pump industry | Spring 2021 | Issue 37

52 Woodlands Drive, Braeside Victoria 3195 PO Box 876, Braeside Victoria 3195 Tel: (03) 9588 6900 Fax: (03) 9588 6999 Email: info@lkdiesel.com.au Web: www.lkdiesel.com.au • Petrol engines up to 13 HP • Diesel engines up to 83 HP • Generating sets up to 30 KVA We provide diesel engine solutions to EMPOWER your business WATER PUMPS ALSO AVAILABLE

AUSTRALIA AS-NZS4020-2005 APPROVED

UK WRAS APPROVAL to BS6920

USA NSF61 LISTED

GERMANY KTW-DVGW APPROVED

POLAND PZH APPROVED

Australian Pipe Friction and Pump Technical Handbooks: vital resources for pump professionals

Pump Industry Australia (PIA) publishes two handbooks which are specifically designed for the Australian pump industry: the Australian Pump Technical Handbook and the Australian Pipe Friction Handbook. These publications are handy reference volumes for those who work and are associated with the pump industry such as manufacturers, distributors, educators, designers, operators and users. Both of the books are easy to follow and can be readily understood with a minimum of technical expertise. It is PIA’s constant aim to ensure that these publications comply with the very latest pumping practice and standards, and as a result both publications have recently been reviewed and updated.

Australian Pipe Friction Handbook

The Australian Pipe Friction Handbook is currently in its fifth edition, having been reviewed and brought into line with the latest Australian Pipe Standards in 2020.

The handbook is split into two sections – the first section covers a series of friction tables which cover the following pipes and tubes, including:

• Commercial steel and stainless pipe

• Large fabricated steel pipe

• Medium and heavy duty galvanised steel pipe

• Uncoated and cement lined ductile iron pipe

• Copper tube

• Brass tube

• Stainless steel tube

• Series 1 and 2 PVC pipe

• Polyethylene pipe

• Rural polyethylene pipe

• Aluminium irrigation tube

• Elastomeric rubber hose

• Concrete pipe

All the above listed tables are based on current Australian pipe and tube standards, except for the commercial steel and stainless steel pipe, a very common pipe used in Australia, which conforms to ASME/ANSI B36:10M-2013 and ASME/ANSI B36:19M-2013

The main changes for this edition are; firstly, the recalculation of the two ductile iron pipe table sets, as the latest standard upgrade involved a change to many internal pipe diameters. Secondly, the addition of an extra page at the start of the commercial steel pipe tables to explain that the tables in this section can be used up to 250mm N.B., for stainless

steel pipe as well as wrought steel pipe.

In addition to the above tables, there are tables for the friction loss of viscous liquids in commercial steel pipe and a chart for the calculation of friction loss in layflat hose.

The second section covers how to calculate the friction loss in a wide range of pipe fittings, valves, etc., together with instructions on how to calculate a pump system total head using the tables in the first section and the fittings in section two. In addition, this section has a range of tables which are useful to the pump engineer.

In summary, the Australian Pipe Friction Handbook covers all you need to know on how to calculate the total head of a pump system.

Australian Pump Technical Handbook

The fifth edition of the Australian Pump Technical Handbook is a widely recognised text that has been produced and designed for the Australian pump industry. The handbook is for those wishing to learn about pumping and to acquire the technical knowledge of pumps and their operation including the overall pump system.

The handbook begins by outlining the units, notations and terms used in pumping, followed by details of the classification of both centrifugal and positive displacement pumps.

The next chapters comprehensively cover the characteristics, selection and application of centrifugal, positive displacement and slurry pumps.

The efficient operation of pump

systems is covered in a chapter detailing where pump and system efficiency losses can occur and how they can be minimised.

The chapter ‘What are pumps made of?’ discusses the metallic and non-metallic materials that pumps are constructed from and provides basic pump material selection data for applications other than water. A table of Australian, European and American material standards is included.

Pipe systems are covered including how to calculate system head which is done in conjunction with the PIA Australian Pipe Friction Handbook

Good intake design is critical to the correct and efficient operation of a pump system and is extensively covered together with how to construct a wide variety of intakes. The common problems to be avoided with intakes – as well as solutions – are discussed.

The pump test chapter covers the standard to which pumps are tested, what data comes from a pump test and the applicable test tolerances.

There are two chapters covering Installation, Commissioning, Operation and Maintenance and Troubleshooting, which discuss what should happen to a pump after site delivery, to the point where the pump is in full operation.

Finally, there are sections covering conversion tables and pumping formulae.

The above illustrates the comprehensive nature of the Australian Pump Technical Handbook, which we recommend to all those with an interest in pumping.

12 pump industry | Spring 2021 | Issue 37 www.pumpindustry.com.au PIA NEWS

revised

updated editions of PIA’s Australian Pipe Friction Handbook and Australian Pump Technical Handbook are available for purchase via the PIA

at

The

and

website

https://pumps.org.au/publications/

A POWERFUL PARTNERSHIP

Volvo Penta. Robust, fuel efficient industrial diesel engines that keep running even in the toughest conditions. Easy to install, operate and maintain. A powerful partnership you can trust all the way from the drawing board throughout the operational life of your engine. Competitively priced complete power-pack units ready for delivery Australia wide with a local support team on hand 24/7. To find your nearest dealer visit www.volvopenta.com

105-515 KW

The future of booster set technology

“When we started to think about Esybox Max, we asked ourselves how to manage the evolution of the Esybox range. It was clear from the very beginning, it could not just be something bigger. We felt we had to bring forward the path of evolution, completely changing the rules of the game for booster sets in residential and commercial buildings. Esybox Max is the outcome of listening to and communicating with many different people who will be in direct contact with the product.”

Introducing a new concept and industry-first in the booster set industry, Esybox Max is an integrated pumping system for pressurisation in commercial building services. Available in two power sizes, it consists of modular elements that allow different configurations to cover the needs of medium/large apartment blocks and high buildings (even over 14 floors). Each unit consists of the single, double or triple connection base and the pumping units – a four-pump system is available with the additional kit to connect two double bases.

Large energy savings are achieved with the DAB inverter combined with a brand new permanent magnet motor. DAB also designed completely new hydraulics, making it leaps ahead in terms of energy efficiency. But it is not just energy efficiency that is at the forefront of this new technology.

Esybox Max will improve the storage efficiency in the warehouse. Where there was once one booster occupying space, you can now fit three twin pump booster sets in its place. This allows people to store the full range on one pallet, meaning a customer can pick up an off-the-shelf booster solution of up to four pumps, the same day.

Keeping it flexible, DAB has the on-site assembly concept. So if you have difficulties getting to the pump's location, due to narrow stairways and corridors etc., you can choose to assemble your booster on-site which will only require moving smaller, lighter boxes into the location then carrying out a quick and easy assembly.

DConnect

The Esybox Max also offers full connectivity and control using DAB’s DConnect technology, which is built into the pump and offers many more advantages than typical BMS systems.

Performance, data storage and remote monitoring support users, and facility managers can control their pumps from anywhere, making sure that the running parameters of the pumps follow project specifications exactly and avoiding any possible site issues for complete peace of mind.

14 PIA MEMBER NEWS | PARTNER SOLUTIONS pump industry | Spring 2021 | Issue 37 www.pumpindustry.com.au

1 Display 2 Inverter 3 Module Wifi/Bluetooth 4 Pressure sensor (delivery side) 5 Pressure sensor (suction side) 6 Non-return valve 7 Two Litre expansion tank 8 Impellers 9 Hydraulic connections 10 Fast connection tool 11 Water cooled permanent magnet motor 12 Handles

LINE UP FOR THE FUTURE

Modular Integration

The most compact and integrated booster set on the market. Connect 1, 2, 3 or 4 Esybox MAX units.

Easy to maintain

Connect and control from anywhere with DConnect.

Easy to move & install

Quick On-Site Assembly.

State of the art efficiency

Leaps ahead in terms of energy efficiency with the DAB inverter, brand new permanent magnet motor and new hydraulics.

0 100 0 20 40 60 80 100 H (m) 200 300 400 500 600 700 800 900 1000 1100 Q (l/min) Esybox Max 60/120 T Esybox Max 85/120 T 2Esybox Max 60/120 T 2Esybox Max 85/120 T 3Esybox Max 60/120 T 3Esybox Max 85/120 T 4Esybox Max 60/120 T 4Esybox Max 85/120 T

MORE

LEARN

DABPUMPS.COM.AU

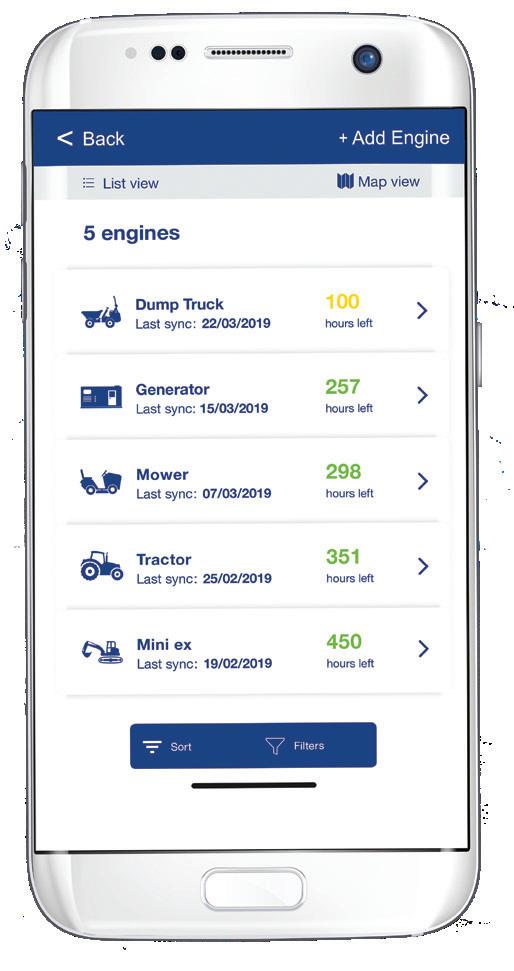

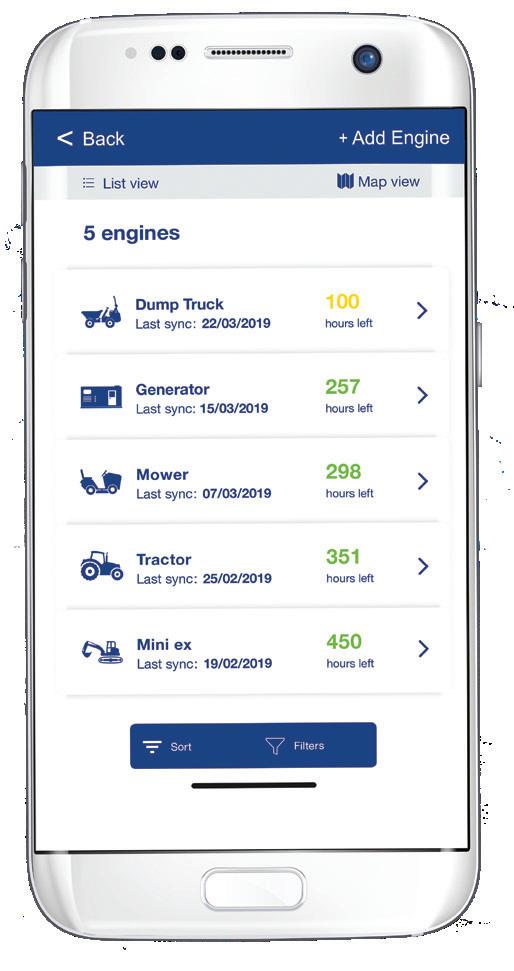

Perkins® My Engine App: taking service and capability to a new level

With Perkins recognised as one of the world’s leading diesel engine manufacturers, AllightSykes is proud to be the authorised distributor of its engines in Australia.

AllightSykes offers both mechanical and fully electronic Perkins engines, with build specification that can be tailored to customers’ needs and applications. This versatility brings engines to the Australian market that are flexible, high performing, fuel efficient and durable – ideal for the harshest of environments.

Perkins engines are also used across AllightSykes range of dewatering pumps, which provide efficient water management solutions to a variety of industries, including mining and construction.

Making monitoring easier

Perkins’ most recent innovation, the Perkins® My Engine App, has just made monitoring service and maintenance history a whole lot easier.

From the convenience of a mobile phone or tablet device, operators are now capable of checking their Perkins engine’s service and operating manuals.

AllightSykes National Aftersales Manager for engines, David Whincup, described the app as “the next level in digital accessibility” for the Australian pump engine market.

“The Perkins My Engine App is an extremely useful tool to have. By simply entering the engine’s serial number into the app, operators are granted access to all the service manuals* for that engine, as well as parts books,” Mr Whincup expressed.

“It is easy for operators to keep track of what needs replacing at the next service and send the information straight to their local dealer. The whole process is now very seamless.”

What is the flow on benefit of this? Saved costs from unplanned maintenance downtime, which can quickly accumulate into significant losses, according to Mr Whincup.

“Not only do Perkins engines help mining operators save in the space of less unscheduled maintenance, but also with the cost of the engines themselves,” Mr Whincup explained.

“To reduce engine operational costs across the lifetime of the machine, Perkins offers low installation costs and fuel consumption.”

An ideal pumping solution

With a design specific for the needs of off-highway machines and a global product support network to minimise downtime, Perkins engines are the ideal solution for pumping applications.

“Perkins has a service life commitment of 8-12 years, following the last engine leaving the production line, depending on application. In addition to this, Perkins will continue to offer parts for older engines if it is commercially viable,” explained Mr Whincup.

“In the unlikely event that you do experience a problem, your local dealer or distributor will be able to assist, providing all necessary information. The Perkins helpdesk is also available as a resource, in which you can liaise directly with Perkins should the need arise,” Mr Whincup concluded.

For more information on Perkins engines and Perkins genuine parts, contact AllightSykes at www.allightsykes.com, csc@allightsykes.com or 1300 255 444.

16 PIA MEMBER NEWS | PARTNER SOLUTIONS pump industry | Spring 2021 | Issue 37 www.pumpindustry.com.au

* Available on UN ECE R96 Stage IIIA and below. Must subscribe to marketing permissions.

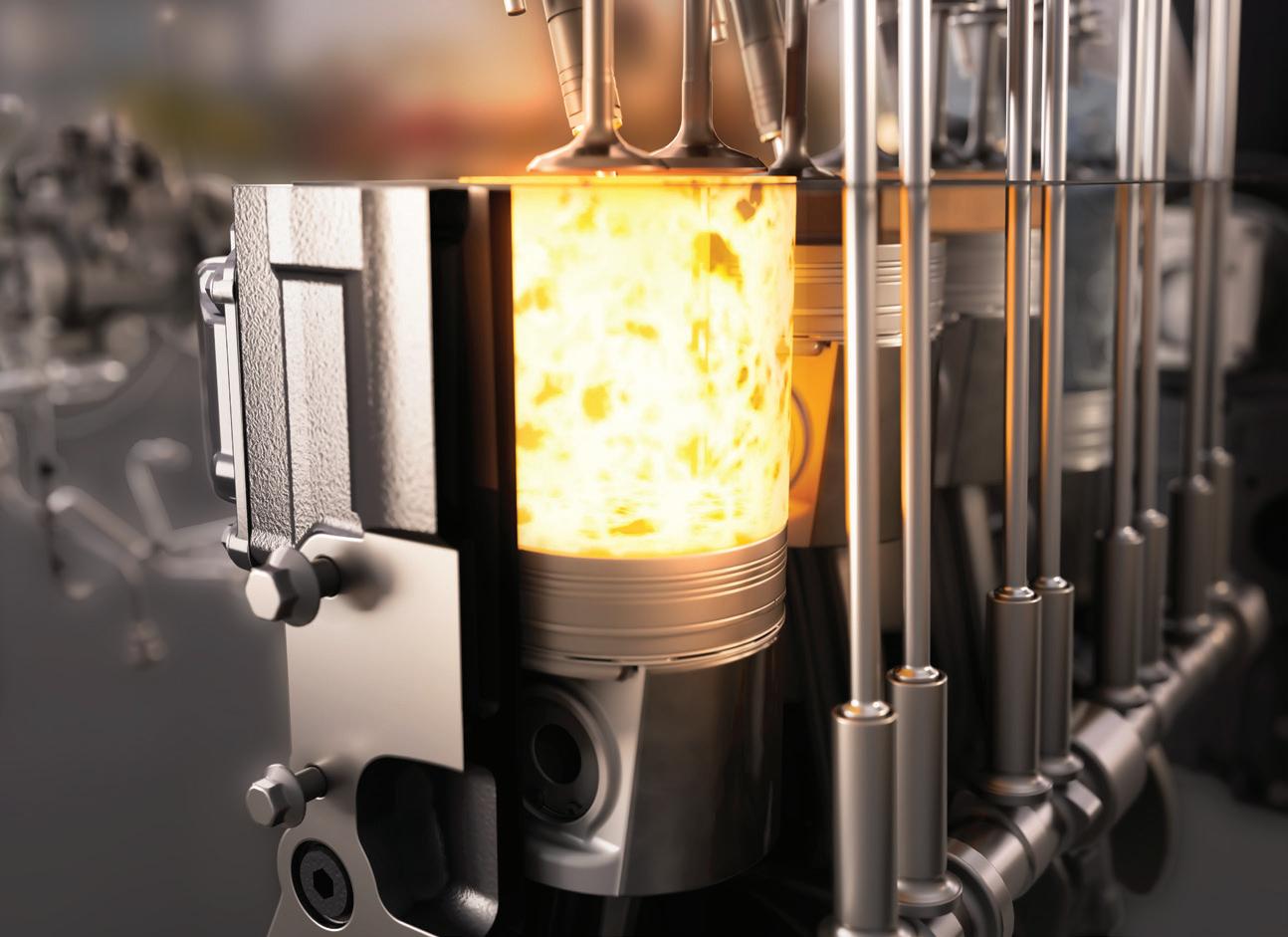

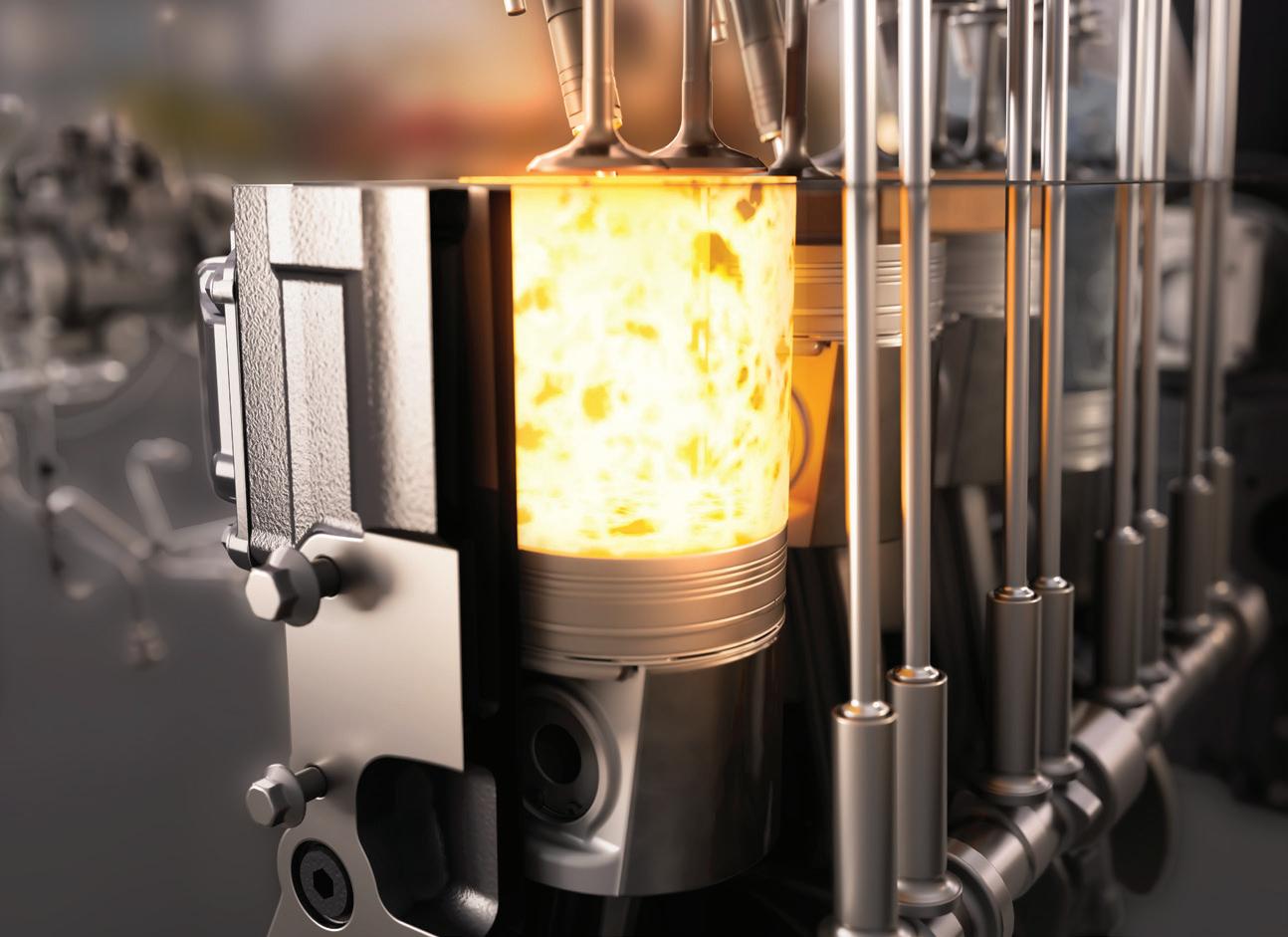

Perkins Parts and Service

The difference is in

Combustion pressure on a piston head is equivalent to 13 tonnes. It’s the same as 12 cars pushing on a 75 mm metal bar, 750 times a minute. That’s why we run billions of hours of tests on our engines and parts.

With genuine Perkins parts, you also get a network of expertly trained technicians to give you the advice and support you need.

AllightSkyes Pty Ltd.

12 Hoskins Road, Landsdale Western Australia, 6065 + 61 8 9302 7000

csc@allightskyes.com

www.allightskyes.com/perkinsenginesfacts

ALLIGHTSYKES PTY LTD. is the appointed Perkins distributor for Australia

the detail

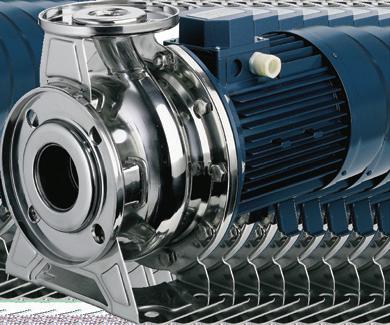

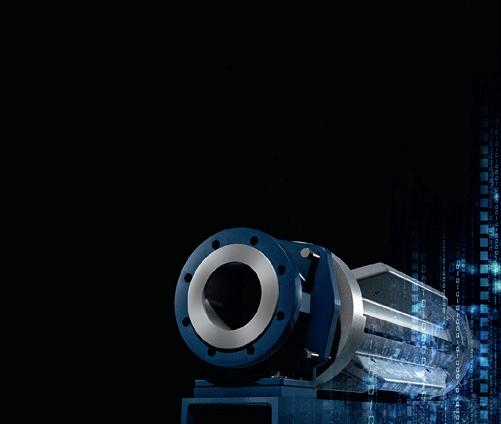

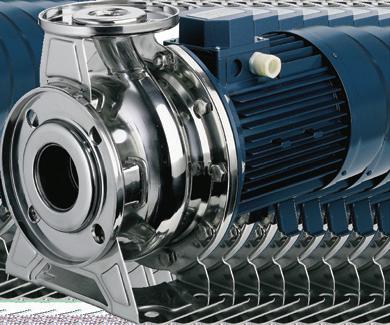

HYDROFORMING PROCESS

OWORLD-FIRST TECHNOLOGY

When Ebara Corporation established its factory in Northern Italy, its main purpose was for the production of stamped stainless steel pumps. As well as utilising the most modern manufacturing techniques and equipment of the time, Ebara also developed and patented their own world-leading processes. The most prominent example of this is the hydroformed one piece volute casing.

nce the product and technique was designed by utilising the latest computer programs, it underwent a strenuous testing program. This included the casings undergoing one million cycles of pressure pulsations between six and 12 bar.

The internal deflection due to pipe strain was also measured to ensure the success of the support structure design.

This technology is clearly seen in Ebara’s 3' series of end suction pumps. These have proven their reliability and value for many years now, and continue to be another world-leading product from Ebara.

To complement the success of the Hydroformed Ebara 3LS (all 316 SS) and 3M (304 SS) series of pumps, Ebara Pumps Australia hase recently introduced the low cost 3D series of pumps.

The 3D model uses the same stamped stainless steel components as the 3M but comes with a cast iron casing. This economical close coupled motor pump to EN733 (DIN 24255) dimensions is available in sizes 32mm 1.1kW up to 50mm 11kW at 2900 RPM.

The pumps are an extended motor shaft design and are fitted as standard with high efficiency IE3 motors (three phase versions).

The 3D pump is made at the Ebara factory in Italy and options include high temperature and hard face mechanical seals.

About Ebara Corporation

Ebara Corporation was founded in Japan in 1912 and consists of more than 88 companies around the world, with a workforce of more than 15,000 people on five continents.

Ebara is now one of the world’s largest pump manufacturers, and its products have been sold and used in the Australian market for over 30 years.

The huge scale of production and distribution is matched by constant commitment to the research, development and design of new products; and the modern technologies for manufacturing them. Ebara products have gained a worldwide reputation for their technology and quality.

Contact your local Ebara dealer or Ebara Pumps Australia for more information visit www.ebara.com.au

Ebara continues to expand the range of products they stock and supply in Australia with two recent additions. For more details contact us at Ebara Pumps Australia or visit our website.

Very economically priced cast iron end suction motor pumps to EN733. They are based on the well proven 3M using the same extended shaft motor and stainless steel impeller, but with a cast iron casing.

A range of robust submersible grinder pumps with a high torque motor & powerful grinding mechanism. Another quality product in the well regarded and proven D’ series of Ebara submersible sewage & wastewater pumps.

18 PIA MEMBER NEWS | PARTNER SOLUTIONS pump industry | Spring 2021 | Issue 37 www.pumpindustry.com.au

MODEL 3 D MODEL DG with powerful grinding mechanism

EBARA STAMPED STAINLESS STEEL PUMPS

Since Ebara developed and patented the hydro forming process, our 3' series of pumps have proven to be very reliable, providing exceptional value.

one piece hydro formed volute

www.ebara.com.au EBARA PUMPS AUSTRALIA PTY. LTD. 7 Holloway Drive Bayswater, VIC. 3153 Ph: 03 9761 3033 sales@ebara.com.au

Looking ahead, going beyond expectations

Robust stamped volute casing

One piece stamping with no weld lines. Supported against pipe strain

Model 3M 304 stainless steel with

economical

extended motor shaft design

MadeinItaly

Model 3LS 316 stainless steel with stub shaft and IEC standard motor

FLEXIDRAG® – THE PREMIUM DRAG HOSE FOR YOUR BROAD ACREAGE IRRIGATION

When getting ready for spring irrigation, you can’t go past Flexidrag®, the premium irrigation drag hose by Crusader Hose. Its world-class revolutionary manufacturing process gives it all the features and benefits you would expect, while assisting farmers in maximising productivity as well as cost efficiency.

Designed to handle Australian conditions

Crusader Hose has been manufacturing layflat hose for over 35 years, and earned the respect and recognition of being a company dedicated to innovation and continuous improvement. One of the toughest hoses to get right, said Francois Steverlynck, Managing Director of Crusader Hose, is the drag hose.

“One of our greatest challenges to-date has been the manufacturing of a truly high-quality drag hose for Australian conditions. Maintaining a low bend radius, an easy-to-roll compact coil, and non-cracking exterior with the high-level UV exposure, all contribute to the demand on the manufacturing of this hose.”

Flexidrag® is an innovative product designed and manufactured to world’sbest standard, after a heavy investment in R&D and factory upgrades. The polyurethane encased linear move and

Australian-made Flexidrag® irrigation hose, the new force in irrigation, is enjoying its second spring season.

Crusader Hose is dedicated to helping Australian and New Zealand farmers get the most efficient use of their travelling, boom and lateral irrigators with its worldstandard drag hose. The improvements made are keeping farmers, like Jay Drew, happy customers.

travelling irrigator hose can withstand high pressures on water guns as well as remain flexible at low pressures. It has a tight bend radius and can withstand extremely high UV conditions. The popular sizes are ~20 per cent lighter to drag around compared to rubber hose, for extra energy-consumption savings.

Flexidrag® in action

The Gippsland region in Victoria maintains 35 per cent of its farms to dairy cattle, and growing their food relies on efficient and consistent irrigation of the broad acreage fields. For this, no wonder travelling and lateral move irrigators are such a frequent sight across the region.

Jay Drew, a dairy farmer in the Traralgon/Sale area, has been using the original Crusader Hose irrigation hose for many years. When it came time to purchase 220m more for his pneumatic laterals, Jay received the newly designed Flexidrag®.

Delighted with the improvements made with the new Flexidrag® hose, Jay said, “I’m really pleased with its capability to work so well under low pressures as it requires a lot less energy. The bend radius is perfect, never had an issue with kinking. It’s hard wearing. It’s great!”

The working pressures at 2.8 bar translates to the low pumping costs associated with Flexidrag®. Since then, Jay has purchased Flexidrag® shorts to use as special joiners for his 4”, 5” and 6” pump outlets.

A range of options to suit various needs

Crusader Hose manufactures Flexidrag® in a large range of diameters from 40mm to 152mm, and in continuous lengths of up to 350m. This Australian-made hose is suitable for lateral or winch irrigation, effluent pumping, as well as feed hose to pivot, and general farm use. It is ultra-flexible, UV-stabilised and quality tested. The warehouse is well stocked with 3” and 4” hose ready for despatch to assist farmers in getting the stock they need on time, every time.

“For farmers seeking a reliable drag hose for their broad acreage irrigation needs, you can’t go past Flexidrag®”, said Francois, “Australian made here in Victoria, Flexidrag® is of world standard and designed for Australian conditions.”

20 PIA MEMBER NEWS | PARTNER SOLUTIONS pump industry | Spring 2021 | Issue 37 www.pumpindustry.com.au

Flexidrag®

The new force in irrigation!

Flexidrag® irrigation hose is Australia’s leading drag hose for lateral and travelling irrigators. It’s a smooth, flexible layflat hose that can be easily stored when not in use – either on an irrigator or in a shed.

With a large range of sizes and lengths available, the Flexidrag® features a perfect blend of superior materials with high-quality construction techniques.

FEATURES

✓ Very flexible at low pressures

✓ Tight bend radius

✓ ≈ 20% Lighter than rubber hose

✓ Abrasion resistant

✓ Low coil volume for easy handling

✓ UV treated

✓ 10-Year pro-rata warranty

✓ Custom lengths

Proven to deliver results in the Australian Agricultural industry!

“I’ve been using the new Flexidrag® hose since March 2020. The hose has a great feel and is easy to wind up on my irrigator. I have been dealing with Crusader Hose since 2007 and their products have helped me grow into the leading potato grower in the Thorpdale Region.”

When you need irrigation hose solutions that are tough, robust, cost-effective, and efficient, choose Flexidrag ®

Contact us today on +61 3 9720 1100 to learn more or request a quote here! https://www.crusaderhose.com.au/flexidrag-irrigation-hose/

Carpenteri Farms, Sam Carpenteri

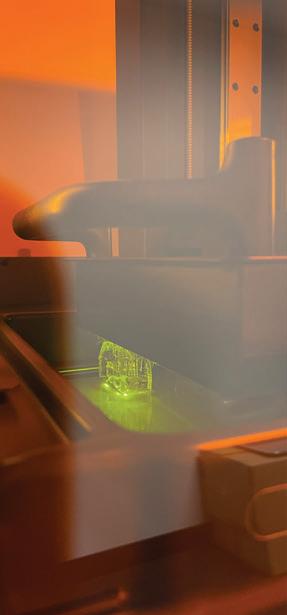

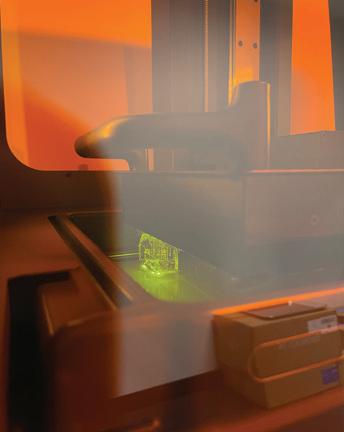

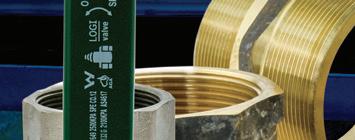

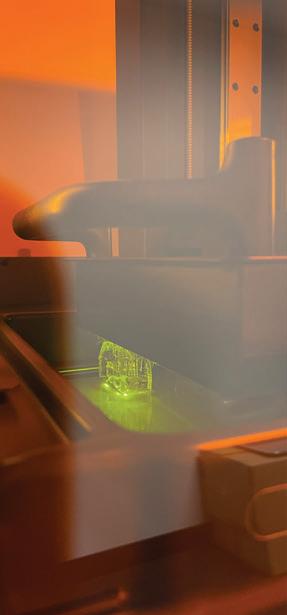

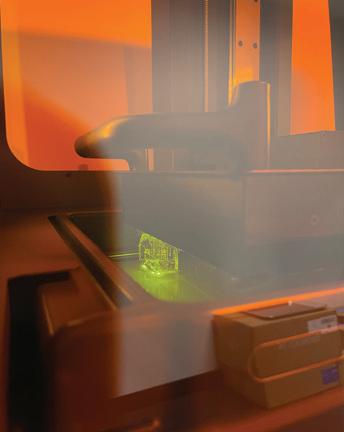

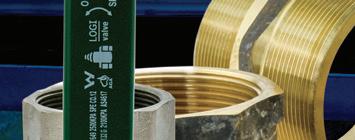

AUSTWORLD ADVANCING AUSTRALIAN-BASED FACILITIES

As one of Australia’s largest family-owned manufacturing, wholesaler and distributor of plumbing solutions, Austworld continues to grow its capabilities across the nation.

Expanding its head office in the booming Gold Coast City industrial district, Austworld is adding over 1000m² of under-roof floor space to accommodate a stateof-the-art testing and engineering facility. With dedication to expanding the manufacturing, engineering and quality assurance divisions of the Austworld team, the new development will assist in delivering high-quality, innovative products with exceptional longevity.

The Queensland facility will include rainwater collection tanks, and leverage solar technologies to support the recycling and the reuse of test water – in best efforts to align consistently with an eco-friendly corporate initiative.

The Austworld multi-function laboratory, research and development centre will extend the level of testing and evaluation of Austworld products beyond that required of simply conforming to Australian standards, but by exceeding them.

Using the latest technologies

Approximately eight unique testing rigs will be coordinated via wireless, and touchscreen smart technologies equipped with data-logging capabilities. Each specifically calibrated to tackle both performance and endurance testing. Premium pressure and temperature rigs will allow Austworld to rigorously evaluate its expansive range of brassware, valves and components, reinforcing their competitive edge in the market.

Additionally, the facility boasts a spectrometer, allowing the Australian team to regularly test the composition of local and imported raw materials to maintain Austworld’s highest standard of integrity.

The latest CNC machines will be a complimentary addition, allowing the teams to machine both brass and plastic to continuously develop

upon the functionality of existing and new products.

Allowing Austworld to remain competitive by bringing innovations to market rapidly, the latest 3D printing capability has been installed and further enhances the ability to design and produce prototypes for customers and industry giants. This technology also enables Austworld to develop stylish, fully functional engineering concepts that can be used for design validation and market feedback. Once models are printed, a surface coating provides an exact representation of the final launched product.

Providing quality products to the Australian market

Austworld provides collaborative, quality design and development services, ranging from concept to high volume manufacturing. Now complemented by the enhanced head office facility, Austworld positions itself to leverage its location and Australian-experienced engineering specialists to drive growth from supporting local tank, irrigation, solar and heating manufacturers with proprietary components.

With limited time delay from technical drawing to 3D sample, Austworld also looks forward to driving the new and replacement tapware market with fashionable designs that meet rigorous standards in anti-vandal materials. Maintaining the ability to adapt swiftly to market trends in interior design and the commercial residential housing sectors, Austworld now builds upon a reputation of durability and after sale support, generated from 40 years strong in the industry.

During the demand from the COVID 2020 residential housing boom, Austworld continued to maintain supplies to both large retail and independent stores. Additionally, the business expanded many of its core commodity ranges and brassware fittings. The 2021 financial year will see Austworld continuing to grow its product variations and lines by investing in Australian infrastructure, competing strongly in the civil and council arenas.

22 INDUSTRY NEWS | PARTNER SOLUTIONS pump industry | Spring 2021 | Issue 37 www.pumpindustry.com.au

Major acquisition creates Australia’s largest pump rental company

The pump industry was abuzz with news of the National Pump & Energy acquisition in August.

NPE had acquired Vortex Group – bolstering its hire fleet, national footprint and personnel count. NPE’s service capabilities expanded to include water treatment and lab services.

NPE managing director, Dave Campbell, said this was a very exciting development for both organisations and indeed the broader pump and power rental industry in Australia.

“This latest acquisition by National Pump & Energy now secures its position as the largest pump rental and specialty dewatering company in Australia,” Mr Campbell said.

National Pump & Energy’s hire fleet now has more than 6,000 dewatering pumps and generators. The company spans 12 branches across five states and one territory, and the team has grown to more than 450 employees.

The acquisition of Vortex allows NPE to strengthen its market offering by:

• Enhancing NPE’s pool of leading technical experts

• Expansion of the NPE national branch footprint

• Assembling the largest ready for rent pump fleet in Australia

• Continuing its Clean Energy, Clean Water and Clean Waste Vision for the future

Specialist dewatering services

NPE is undoubtedly Australia’s largest and most proficient dewatering specialist. Servicing mining, construction, municipal and heavy industry across the country, NPE offers professional customised solutions for:

• Mine dewatering

• Civil construction

• General construction

• Heavy industry

• Site drainage

• Slurry pumping

• Stream diversions

• Process water supply

• Main drainage

• Wastewater

• Emergency water management

• Sewage bypass

• Emergency containment

• Transfer systems

• Infrastructure upgrades

• Wellpoint dewatering

• Sludge removal

• Water Treatment

The experienced team have expertise in all facets of water management and dewatering.

Trust the experts at NPE.

Call NPE today on 1800 PUMP RENTAL.

24 INDUSTRY NEWS | PARTNER SOLUTIONS pump industry | Spring 2021 | Issue 37 www.pumpindustry.com.au

Adelaide | Brisbane | Darwin | Kalgoorlie | Karratha | Mackay | Melbourne

Mount Isa | Newcastle | Perth | Port Hedland | Sunshine Coast | Sydney

WATER SUPPLY & SELF PRIMING PUMPS

VARIABLE SPEED DRIVE PUMPS

CIRCULATOR PUMPS

SUBMERSIBLE PUMPS

PACKAGED PUMP SETS

PACKAGED PUMP STATIONS

“ Maxijet is a great organisation with quality pumps and products. The staff are professional and always very helpful. Thanks for the help and support you have always provided.”

Steven Pavlic - The Pump Guy

AUSTRALIA PTY LT D

CALL US FOR EXPERT ADVICE TO HELP YOU CHOOSE THE RIGHT PRODUCT OR SOLUTION FOR YOUR PROJECT Systems, Solutions, Capability Phone: 03 9336 1000 Fax: 03 9336 1099 Email: sales@maxijet.com.au Web: www.maxijet.com.au 32 McGregors Drive, Keilor Park Vic 3042

WATER PUMPS MADEIN ITALY

Temporary solution for a wastewater plant

The Dungog Wastewater Treatment Plant (WWTP) in New South Wales’ Hunter Region was commissioned in 1938 – making it over 80 years old – and was acquired by Hunter Water Corporation (Hunter Water) from Dungog Shire Council in 2008. This plant services a township of just over 2,000 residents (just north of Newcastle) and is smack in the middle of dairy and timber country. The existing plant has just completed a $28 million upgrade project to improve water quality, with Polymaster supplying two self-bunded chemical tanks with a dosing system which played a critical role in ensuring wastewater continued to be treated during the build.

The new upgrades will replace the plant's aging infrastructure and provide the town of Dungog and surrounding areas with a modern wastewater treatment plant, allowing for better reuse of effluent and recycled water, and improved water quality for the community. Hunter Water Managing Director, Darren Cleary, said the major upgrade would also help deliver improved environmental outcomes.

Client requirement

The project brief was to build a temporary plant off to the side while the client demolished the old plant and built a modern facility without disrupting the treatment plant.

One critical component was the dosing of sodium hydroxide into the wastewater. The build team required a complete solution they could connect and turn on without building unnecessary infrastructure around it, which ultimately would need to be torn down in the new build.

Solution provided

With any new build, there are complexities that need to be thought through. This particular design team had an added challenge of 'shoe-horning’ a new plant on the same site as the existing plant, which had to remain operational at all times.

Polymaster provided two 30kL selfbunded chemical tanks with a dosing system to help dose sodium hydroxide into the wastewater. A fully integrated dosing system was housed within each cabinet of the 30kL self-bunded tanks. As sodium hydroxide is suitable for Polymaster’s polyethylene tanks, it was a perfect solution.

The designers provided Polymaster with a detailed P&ID for the dosing system to ensure they received a system that ideally suited their application. Polymaster’s self-bunded tanks comply with AS3780 (bund capacity of 110 per cent), so the installation crew did not require the expensive and unnecessary construction of a concrete bund.

Ultimately, the end solution

Polymaster provided is a cost-effective and efficient one – saving time and money. In addition, the installers were able to connect the 'turnkey system' with minimal on-site works, enabling the plant to operate continually. Great job to all involved!

The Dungog plant is now complete, and Polymaster is super pleased to have played a little but crucial part in keeping the operation humming along during the build.

The plant is a showpiece of modern technology and innovative design.

Scope of work

• Product design

• Product manufacture

• Engineering

• Delivery

26 INDUSTRY NEWS | PARTNER SOLUTIONS pump industry | Spring 2021 | Issue 37 www.pumpindustry.com.au

Secure IBC storage & decanting solutions

Polymaster’s unique Enclosed IBC Bund solves many of the problems associated with IBC storage and chemical/fluid decanting in a weather resistant, purpose-built enclosure.

Æ Full weather protection – stops rain entering the enclosure

Æ Easy forklift loading with wide forklift access from both side and back

Æ 250ltr day tank

Æ Lockable cabinet to keep system secure

Æ Venting by two sides

Æ Viewing windows incorporated into the doors

Æ 110% bund capacity complies with AS3780

Æ Sight tube and low-level alarm available

Æ Chemical resistant – high grade polyethylene construction

1800 062 064 | polymaster.com.au

View Video

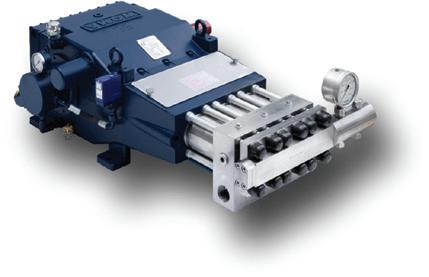

What to look for when purchasing positive displacement pumps

When it comes to choosing the right positive displacement pump for an application, efficient, reliable and trusted products are integral qualities to look for. Finding a manufacturer with established expertise and knowledge can make the process a lot easier, saving you time and money.

For Roto Pumps – a global manufacturer of positive displacement pumps – a strong foundation of experience; efficient, reliable and readily available stock; and cost-effective solutions have seen it become a global leader in the pump industry.

Celebrating 20 plus years in Australia

In 2001, Roto Pumps established a local branch in Australia with warehouse, assembly and marketing infrastructure to provide expertise in positive displacement pumping solutions to various industries across Australia.

This followed on from the Roto Product being accessed in Australia via a distributor network for over several years prior to this. This gave it a very good understanding of the Australian market when its office was established and knowing that, as with any market, success is driven by having a quality product, stock levels to meet the market requirements, good prices, technical support at all levels, and readily available spare parts, Roto Pumps started to see success.

Its initial strategy was to support local distributors, original equipment manufacturers, contractors and select end users in their endeavors to meet their varied process requirements, and 20 years later Roto Pumps still has very strong significant relationships with most of these early customers.

Understanding and supporting local requirements became more critical, and

in order to provide localised expertise, this led it to establish Territory Managers in the states of Victoria, New South Wales and Queensland in 2006.

Considered investment in key personnel has allowed Roto Pumps the opportunity to consistently improve its level of customer support over the years which, when combined with its expansive market-proven product range, has seen continued growth of the company over the years.

This philosophy, focused on customer service, is not new to Roto Pumps Ltd; the company has been providing a high level of service worldwide for over 52 years and will continue to pursue the highest standards possible in order to meet ever-changing customer requirements.

A pioneer in manufacturing

Known for pioneering the manufacturing process of progressive cavity pumps in India in 1968, Roto Pumps has continued to grow into one of the most trusted global leaders in the field. Today, the company supplies pumps to more than 10,000 customers across 50 countries and has installed over 250,000 pumps globally.

Throughout its five-decade journey, Roto Pumps has also established operations in the UK, South Africa, US, Germany and Malaysia thanks to its highly dedicated team and passion towards research and development of highly efficient positive displacement pumping solutions. Now, with 20 years of experience in the Australian market,

Roto Pumps has established itself as experts in application engineering i.e. understanding complex pumping requirements, handling critical media, and optimising pump lifecycle cost. It is also credited with supplying customised pumps in different materials like Hastelloy, Super Duplex, Tungsten Carbide Coatings, and Double Hard Chrome Plating, etc. In addition to pumps, its stators are world-famous for their stringent quality.

Roto Pumps' in-house captive elastomer manufacturing unit manufactures world-class quality stators conforming to international standards. To deliver quality stators, Roto Pumps procures raw material from certified vendors and has implemented strict process control and quality checks.

A leader of innovation

Roto Pumps is also a leader of innovation in pumping solutions. Some of its key innovations include: Roto KwikMaintenance in Place Pumps for quick maintenance of Roto Progressive Cavity Pumps without removing pipelines; the Tirrana Agriculture Progressive Cavity Pump range for agriculture and light industrial duties; and the upgraded Biomix and Biomass Progressive Cavity Pumps. Roto Pumps believes in customer satisfaction and has a team of experienced application and sales engineers in Australia who completely take care of every customer’s concern, right from receiving the inquiry to providing prompt after sales support.

Roto Pumps Australia's capabilities

• 20+ years of strong presence in Australia's robust supply chain network

• Strong sales and service support team in Australia

• Readily available pumps and parts stocks

• Cost-effective and customised engineered packages

28 INDUSTRY NEWS | PARTNER SOLUTIONS pump industry | Spring 2021 | Issue 37 www.pumpindustry.com.au

Launching E-shop Portal for shopping Tirrana Range of Agricultural Pumps Celebrating 20+ Years Of Successful Operations In Australia eshop.rotopumps.com.au Buy Conveniently With Just A Click Surface Agri Pump Roto Spares Complete Pump Package Multipurpose Pump RetroFit Spares CALL US TO KNOW MORE : 0397945200 I nd ust ries We Serve: Sug ar • Biogas • Pap er • Wast ewat er • Oil & Gas • Marine • • Paint s • C • Fo o d & Beverag e Mining & Exp lo sives hem icals RO TO PUM PS L TD . (AUSTRALIA) Gl o b al Pr es en ce : Au s tral i a | I n d i a | Un i ted Ki n g d om | S ou th Afr i ca | USA | Ger m any | Malaysia w w w . r o to p u m p s . co m . au | Em ai l : s al es @r o to p u m p s . co m . au 20+ years o f st ro ng p resence in Aust ralia Ro b ust sup p ly chain net wo rk St ro ng sales & service sup p o rt t eam Read ily availab le p um p s & p art s st o ck Co st-effect ive & cust o m ized eng ineered p ackag es YEARS IN AUSTRALIA

TOP EIGHT WAYS TO IMPROVE

ENERGY EFFICIENCY IN PUMPS

30 pump industry | Spring 2021 | Issue 37 www.pumpindustry.com.au ENERGY EFFICIENCY

Pumping systems are energy intensive, accounting for nearly 25 per cent of the energy consumed by electric motors, and 20 to 60 per cent of total energy usage in a number of industrial, and water and wastewater treatment facilities. While system changes in pumping requirements, normal wear and tear, and build up in pipes can lead to decreased efficiency over time, specification of the right pump for a particular application that looks beyond the initial cost is commonly overlooked, leading to long-term problems and higher than needed power costs. By pump manufacturers, end users and design engineers working closely together to properly match pump performance and system requirements, pump energy costs can be reduced by an average of 20 per cent in many cases. Here, we look at the top eight things pump users can do to improve energy efficiency.

1. Be wary of oversizing a pump

A pump is generally considered to be oversized when it is not operated within 20 per cent of its Best Efficiency Point (BEP), but if the duty point falls within 50 and 110 per cent of the BEP flow rate, it is usually considered acceptable. This range allows for a margin of error in case the actual resistance curve is overestimated.

There are a number of reasons a pump can be oversized. One reason is that the pump is sized early in the planning and design phase using estimated values for pipework and fitting losses. Due to the need to estimate the equipment requirements, as well as the possibility of the published literature having different reference values for flow resistance coefficient or fittings losses, there is a certain degree of error that can occur when specifying the pump.

Another reason a pump may be oversized is to account for the system design to potentially be expanded in a few years, a correctly sized pump for the current conditions would be unable to meet possible future additional demand. Sometimes a “safety margin” will be added and a larger pump procured and installed to cater for a future expanded system.

There are a few other reasons oversizing may occur, including:

• A pump was urgently needed and the right size was out of stock

• A pump was selected from the spares inventory due to budget constraints

• A new pump was bought to replace an existing pump that was already oversized

• A pump as oversized to account for expected build up of corrosion products on the pipe interior, which

would increase the pump total head requirement

• A “safety factor” may be added to increase pump capacity and head to counter the effects of wear

However, whatever the reason for oversizing, it will have the knock on effect of having higher energy costs due to a higher performance in terms of flow and pressure requiring, more power from the motor, which can lead to unnecessary energy consumption. It is not uncommon to find applications where oversized pumps are being used, as engineers will often specify a pump with a margin of safety in terms of the pump’s duty compared to what the application actually requires. For example, rotodynamic pumps, such as centrifugal pumps, are known to be typically oversized by 20 to 30 per cent. While some oversizing can be good to compensate for uncertainties in the design process as noted previously, a pump that will be operating as close as possible to its BEP will significantly improve its energy efficiency and reduce energy use.

An oversized pump can be identified in a number of ways, including:

• If it needs to be throttled to achieve system requirements

• Has a high bypass flow rate

• Has a flow rate that varies more than ten to 20 per cent from the pump’s BEP flow rate

• If there is excessive flow noise

• If bearings and seals need frequent replacement

• It has intermittent operation, such as pump cycling

2. Trim or replace the impeller If a pump is oversized, rather than replace the entire pump and avoid

31 www.pumpindustry.com.au pump industry | Spring 2021 | Issue 37 ENERGY EFFICIENCY

costly operating procedures such as throttling to improve energy efficiency, a relatively cost-effective way to reduce the pressure and flow produced is to trim or replace the impeller. Trimming involves machining the impeller to reduce its diameter. However, it should be limited to about 75 per cent of the pump’s maximum impeller diameter, and as the impeller is shaved, the clearances between it and the casing become larger, resulting in greater flow recirculation and reduced pumping efficiency if it is shaved excessively.

By trimming the impeller, its top speed is reduced, which reduces the amount of energy imparted to the pumped fluid, resulting in the pump’s flow rate and pressure to decrease. Therefore, in applications where the current impeller is creating excessive head, a smaller or trimmed impeller can improve efficiency.

Pump casings and shafts are designed to accommodate impellers in a range of sizes, and many pump manufacturers provide pump

performance curves indicating how various models will perform with different impeller diameters or trims. The impeller should not be trimmed any smaller than the minimum diameter shown on the curve.

3. Use a variable speed drive (VSD)

VSDs allow the pump to operate near its BEP at any head or flow by varying the rotational speed of the motor to achieve the actual head and flow demand of the application, rather than what the pump can produce.

One of the main reasons for using a VSD is to improve energy efficiency by reducing unnecessary energy consumption in the scenario where it slows the motor down on a pump that was oversized at the specification stage. The second major reason for using a VSD for increased energy efficiency is where the application requires vastly differing duty demands on the pump at different times.

The amount of energy that can be saved by using a VSD is dependent on

the application and its requirements. In the water and wastewater industry it can often save more than 30 per cent of energy usage; when used with irrigation pumps, power consumption can be reduced by up to 75 per cent; and when fitted to a vacuum pump for use in dairy applications, energy savings of between 40 to 63 per cent can be made. Therefore, while VSDs do come at a cost, as can be seen, in many cases the cost savings they can provide justify the investment.

4. Pumps in parallel

An alternative to using VSDs for a system where there are multiple different duty requirements is to install multiple pumps to provide the flexibility in the flow rates that need to be delivered. Compared to a single pump, installing multiple pumps provides the system with greater operational flexibility, it will have a higher efficiency, the system can continue to function if one pump fails, and there are lower maintenance requirements. One of the

32 pump industry | Spring 2021 | Issue 37 www.pumpindustry.com.au ENERGY EFFICIENCY

common configurations for this setup is to install a small pump to operate low flow rates and large pumps to cope with the maximum design flow. This ensures none of the pumps need to operate far from their BEP.

However, key to achieving these benefits is correct pump selection as reliability and overall system efficiency can be compromised if the pumps are not properly selected for parallel pumping, or they are not operated in the most optimum combination. This problem is not uncommon and can cause issues such as one of the pumps operating at shut off, resulting in overheating and failure. In order to select the most optimal pump combination, the energy effectiveness (gmp/kW) of each pump should be calculated and then the single pump or pump combination that yields the highest energy effectiveness should be selected.

5. Optimise piping

While piping can be optimised once installed, it can be difficult to fix so it is important to spend time during the design phase of a pumping system to get it right from the start to ensure pressure drops are minimised by avoiding sharp bends and sudden changes in pipe sizes. Low loss valves and fittings should be used and pipe selection should balance the initial cost of the pipe with the cost of pumping fluid through it, for example large pipes might be more expensive, but pumping costs are lower as there are less friction losses.

By optimising the piping, frictional pressure drops will be limited, which in turn will improve energy efficiency as the energy required by the pump to overcome such losses is reduced.

6. Review the motor

Like oversized pumps reduce the energy efficiency of the system, oversized motors can also contribute to this. There are a number of reasons an oversized motor may be specified, including catering for a possible future increase in pumping capacity, where there are load fluctuationsor voltage imbalances, and where the correct sized motor is not available when sourcing equipment.

There are options on the market to avoid oversizing the motor, with some being developed that are able to accommodate short-term overloads and therefore preventing the need to oversize. High efficiency motors can also be installed which provide a range of benefits, including energy cost savings, reduced breakdowns from improved design and construction, and reduced sensitivity of power factor and efficiency to voltage and load fluctuations.

7. Control systems

It is not uncommon for pumps to be operating unnecessarily, resulting in more energy being used than is needed. Installing a control system will enable the pumping systems to be controlled remotely, allowing them to be started and stopped depending on the pumping requirements at the time. For example, where multiple pumps are in operation but only one is required for the current flow rates, the other pump(s) can be stopped and restarted at a later time when a high flow rate is needed.

8. Pump wear and maintenance

Pump wear is a key area where energy efficiency is reduced, with losses ranging from 10-25 per cent. Most wear will occur in the first few years of operation

and will cause a pump’s BEP to move to the left on the pump curve. Signs of wear include cavitation, increased clearance between fixed and moving parts, wear in rings and bearings, and packing adjustment on the pump shaft.

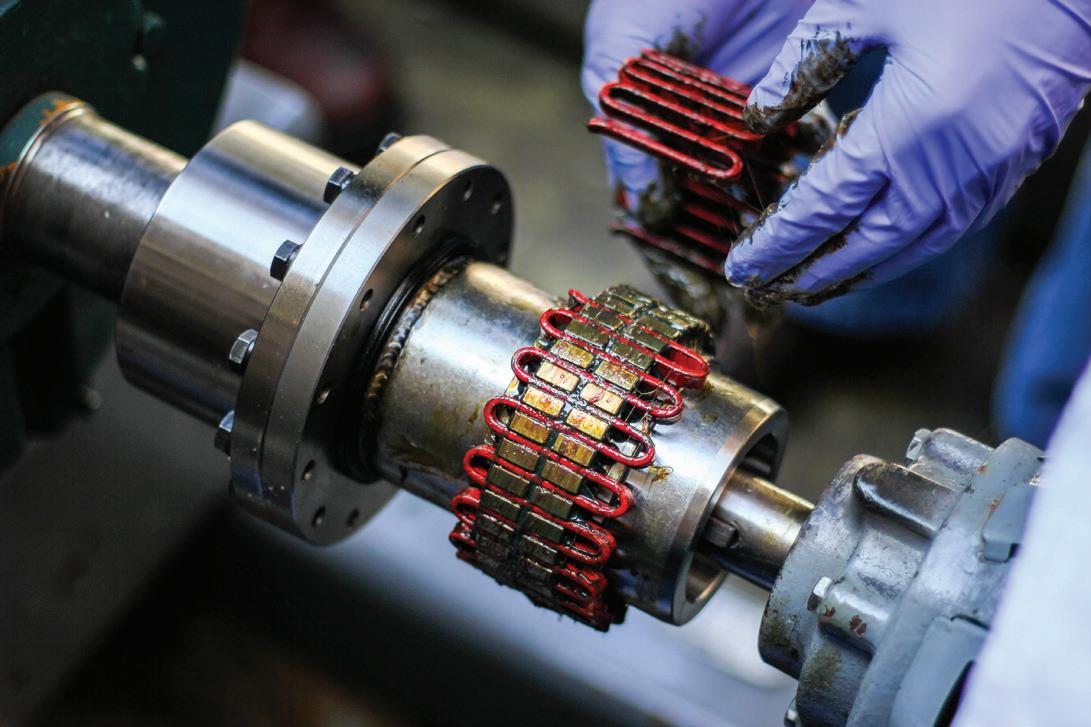

While wear is inevitable, ensuring routine maintenance is undertaken will help reduce the efficiency losses caused by wear, and slow down the wear process. This can result in energy savings between 2-7 per cent. Proper upkeep and maintenance includes replacement of worn impellers, bearing inspection and repair, bearing lubrication replacement, inspection and replacement of packing and mechanical seals, wear ring replacement, and pump/ motor alignment check. When the pump gets to the stage where it’s running too inefficiently and maintenance is not improving it, then replacing the pump is the best option to reduce the long-term energy costs.

As well as maintaining the pump, cleaning and maintaining the pipework will also influence the energy efficiency of the system.

Prioritising changes

This article has looked at eight ways that energy efficiencies can be realised in a pumping system, however, not all points will be suitable or achieve the same amount of energy efficiency for all applications. Any changes need to be prioritised depending on the degree of energy efficiency likely to be realised for a certain application and its individual requirements, as well as the type of pump in operation, e.g. centrifugal pumps typically have the best overall potential for energy savings compared to other pumps.

UNITED PUMPS

33 www.pumpindustry.com.au pump industry | Spring 2021 | Issue 37 ENERGY EFFICIENCY Specialising in custom design, manufacture, repair and service of centrifugal pumps for over 30 years • Complete range of API 610 (ISO13709) • Hydraulic and mechanical design • Custom engineering, retro-fit, redesign • Performance testing • Service and repair

www.unitedpumps.com.au T: +61 3 9464 9500 31 Western Avenue, Sunshine Victoria 3020, Australia E: unitedpumps@unitedpumps.com.au

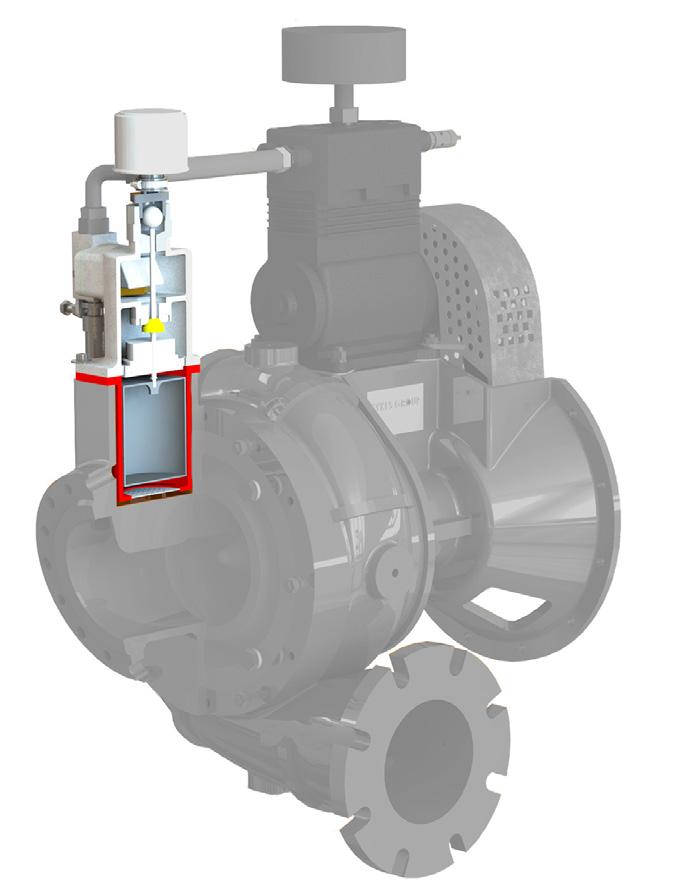

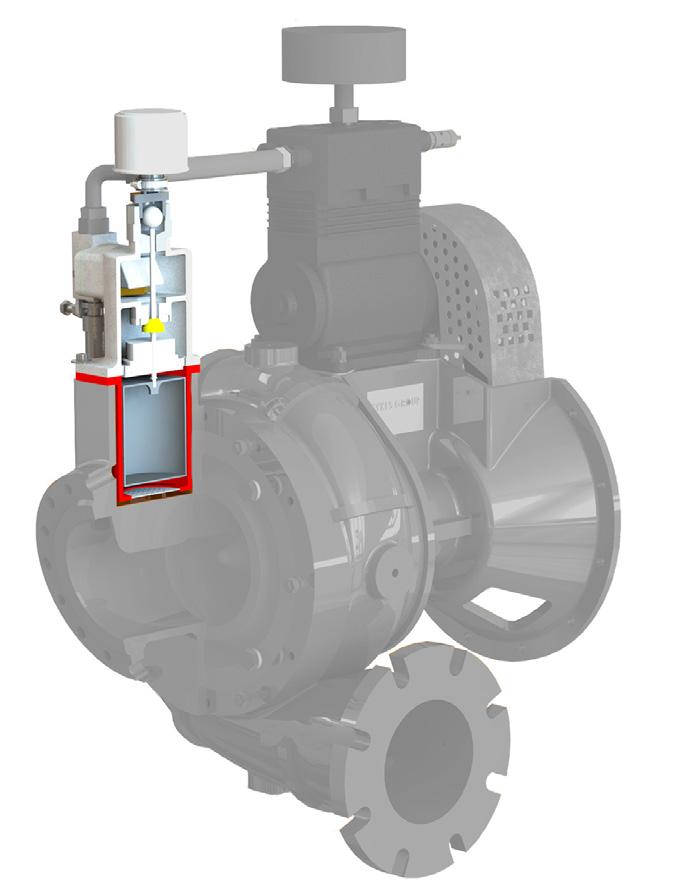

Efficient priming and Anti-Spit technology: AllightSykes’ recipe to the smart pump

It is widely known that priming a dewatering pump is crucial, both for its ability to meet the intended application and to reduce unplanned maintenance. Failure to do so can result in mechanical seal leakage and significant damage to the pump’s components.

AllightSykes’ compressor priming system allows customers to dry prime their pump without the need to manually fill the suction line or use a wet prime tank.

The compressor prime design employs compressed air which is passed through a Venturi Jet and nozzle that evacuates air from the suction and pump, creating a vacuum and allowing atmospheric pressure to force water into the pump.

This allows the pump to automatically prime and reprime without the need to manually fill the pump with water.

As any pump specialist knows, once the pump has been primed, the nozzle constantly spits out a small amount of the pumped fluid. This discharge from the priming system is usually discharged to the ground and the surrounding environment.

AllightSykes’ new Anti-Spit technology mounts on top of the pump’s priming tee and prevents water discharging out the nozzle once the pump is primed. This allows the pump to be used on environmentally-sensitive applications such as sewage bypass, contaminated water and harsh chemicals without the need to run a hose from the nozzle discharge back to the sump.

The Anti-Spit system not only creates a more efficient pump, but also addresses the market’s need to be more environmentally conscious. With environmental responsibility in mind, AllightSykes’ Anti-Spit technology has come to fruition.

Through innovative design, the Anti-Spit technology can now be retrofitted to any of AllightSykes’ existing products.

For more information, contact AllightSykes at www.allightsykes.com, sales@allightsykes.com or 1300 255 444.

34 pump industry | Spring 2021 | Issue 37 www.pumpindustry.com.au SMART PUMPS | PARTNER SOLUTIONS

LEADING THE WAY WITH NEW TECH

Over 50 years. This is how long we’ve been producing some of the worlds toughest dewatering pumps. The driving force behind our reputation as a global front runner in water management? Quality engineering and extensive experience. AlllightSykes’ latest innovation, Anti-Spit, is making our pumps more intelligent than ever.

ANTI-SPIT TECHNOLOGY

The new anti-spit technology mounts on top of the pump’s priming tee and stops water from discharging out of the nozzle after priming the pump. This means that sewage bypass, contaminated water and harsh chemicals, no longer discharge to the ground and surrounding environment.

Through clever design, AllightSykes antispit technology brings to you a more efficient and environmentally conscious pump. The best part about this new tech? Even your older pumps can be young again - with retrofit being available to all of our existing products!

AUSTRALIA | NEW ZEALAND | NORTH AMERICA | SOUTH AMERICA | DUBAI | ASIA | AFRICA W allightsykes.com E sales@allightsykes.com T 1300 255 444

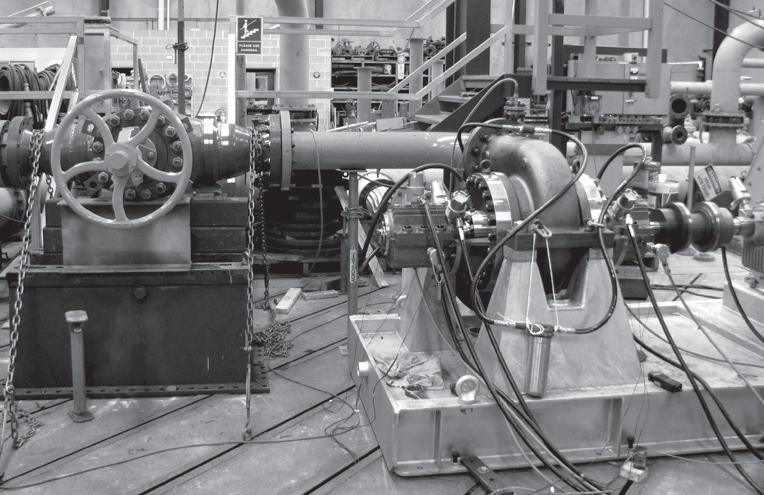

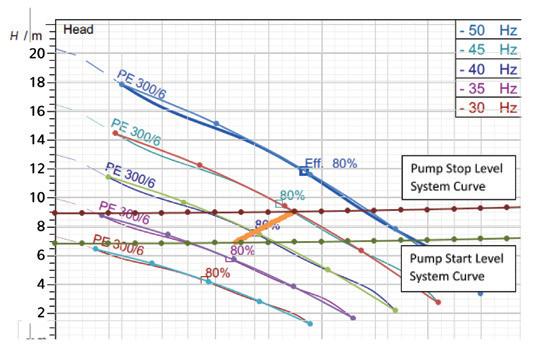

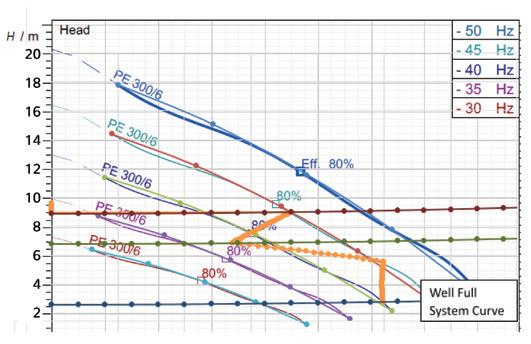

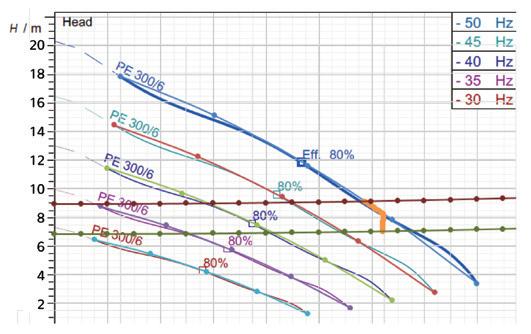

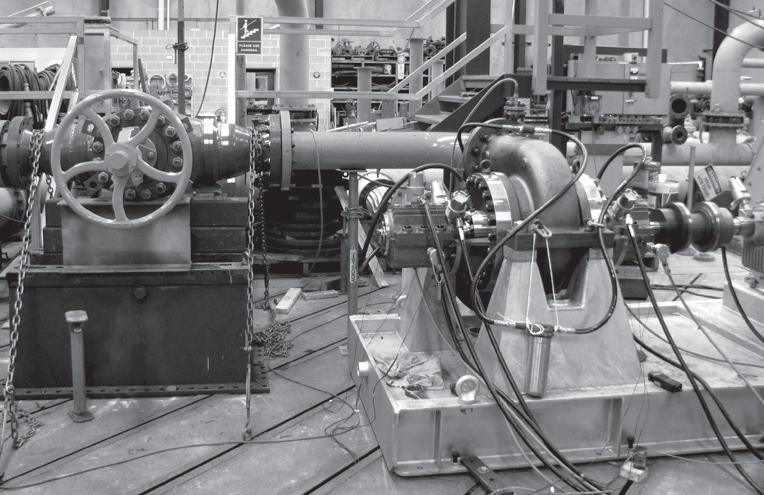

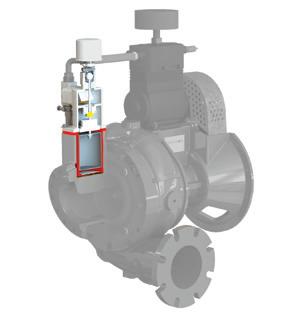

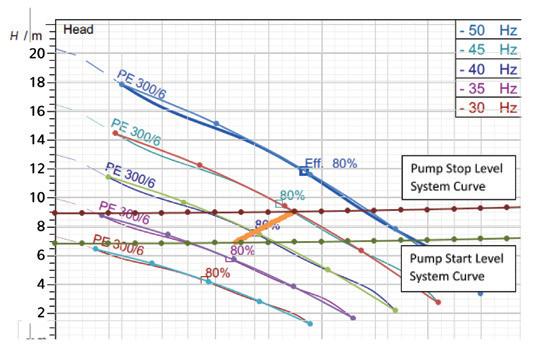

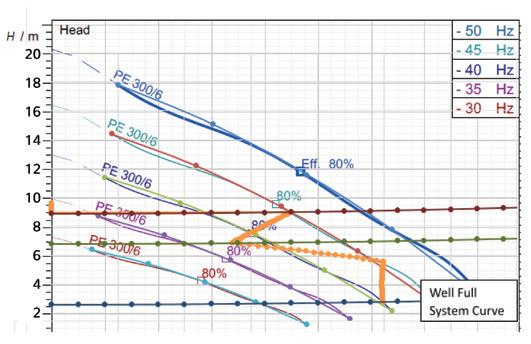

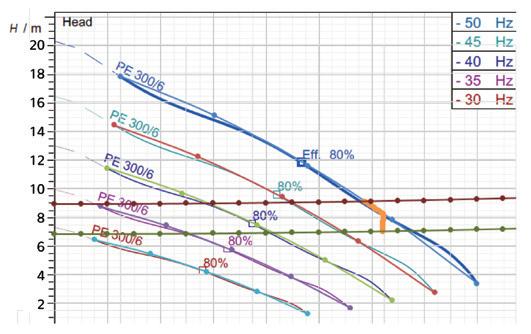

FLOW PREDICTION TOOL FOR VARIABLE SPEED PUMP STATIONS

Variable Speed Drives (VSD), also known as variable voltage variable frequency drives or pulse width modulation, are commonplace in water pump stations where they allow reliable pressure or flow regulation and substantial energy savings simultaneously. In sewage pump stations, the use of VSDs is less widespread, but through the use of daily cleaning cycles, high torque settings and reverse-run subroutines, the major obstacles to widespread acceptance are being overcome.

36 pump industry | Spring 2021 | Issue 37 www.pumpindustry.com.au SMART PUMPS

By Troy Leyden, Operations Engineer, Fitzroy River Water (a business unit of Rockhampton Regional Council)